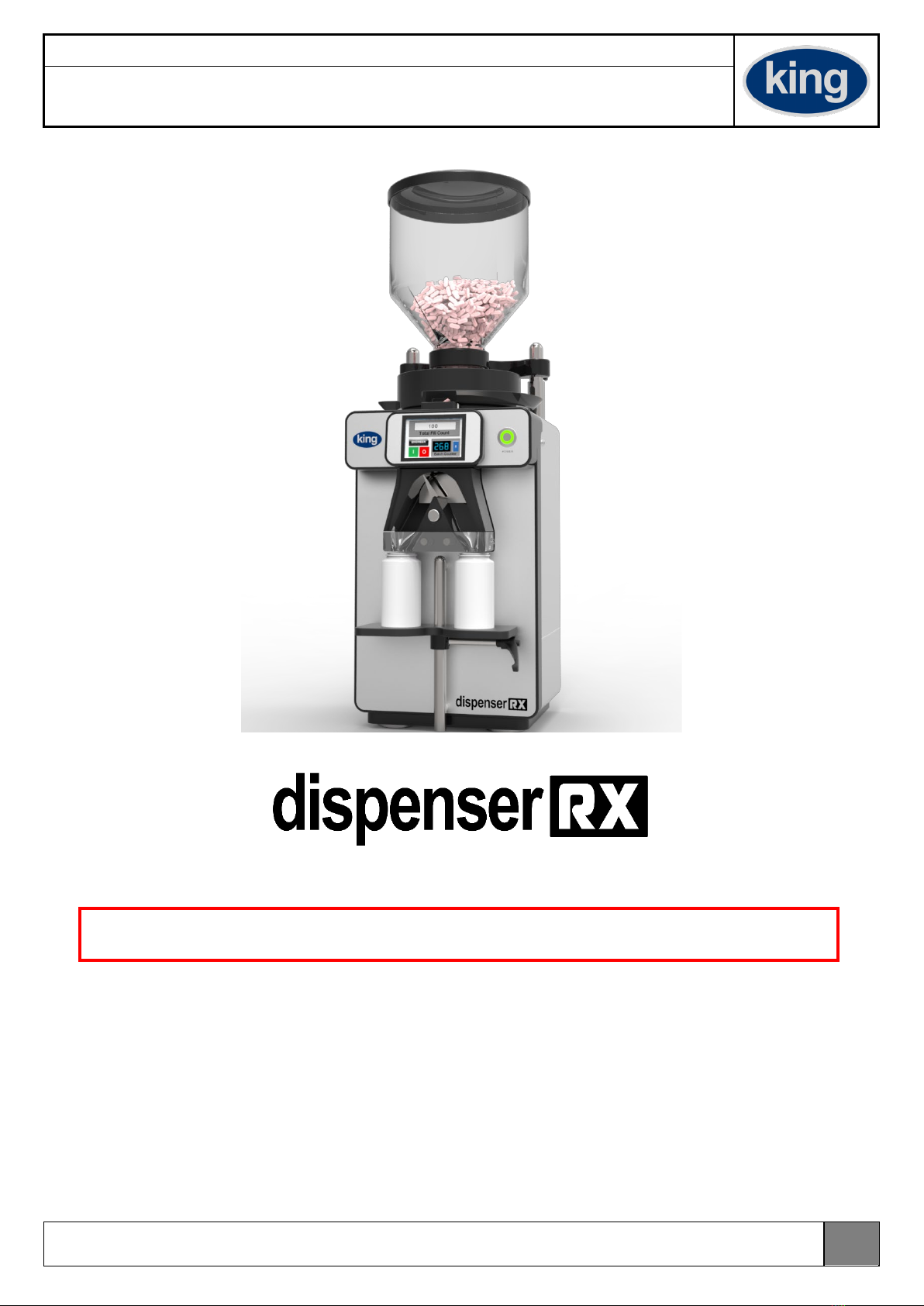

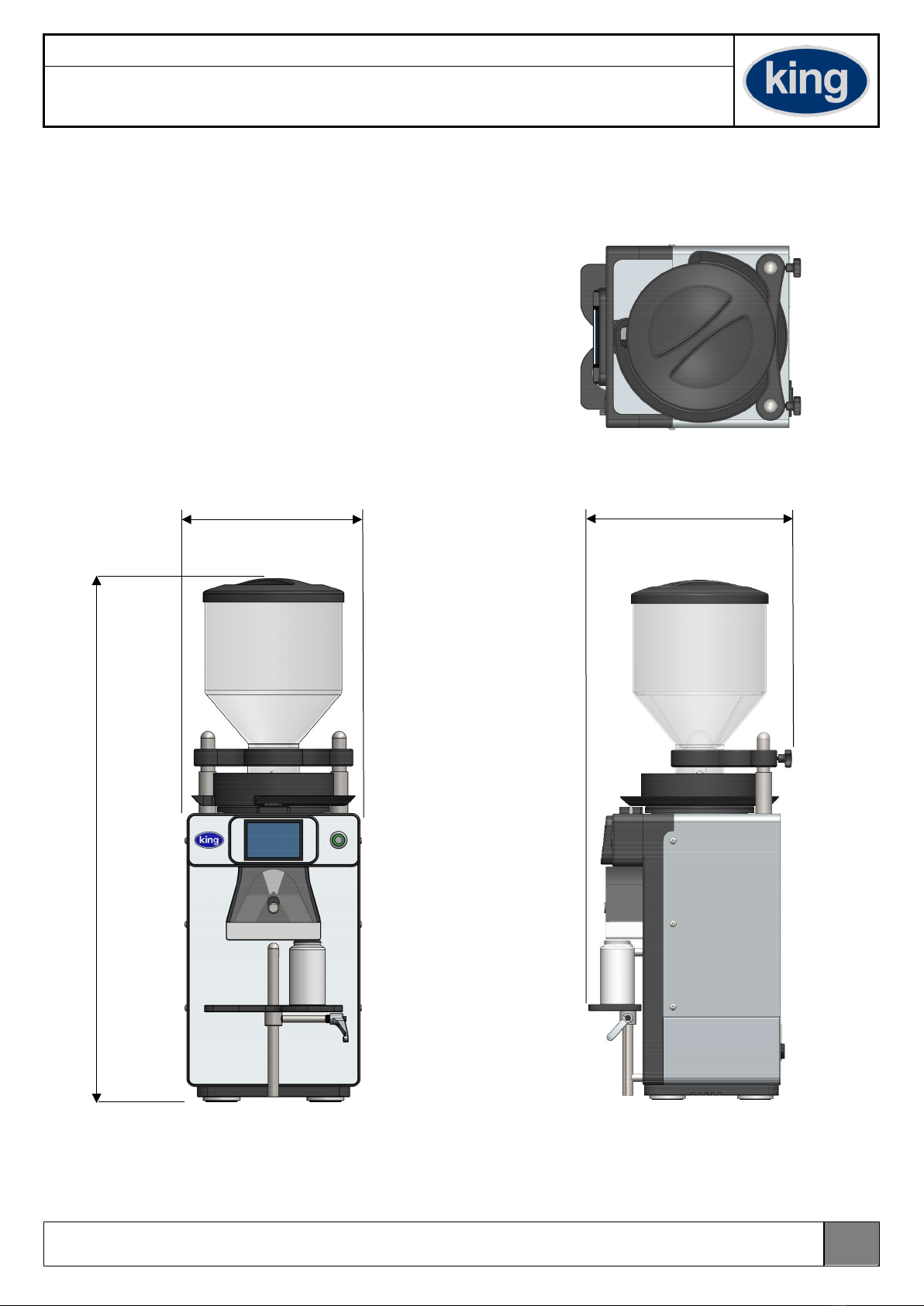

Model: Dispenser Rx

Serial Number: 5780/14

Instructions Manual Dispenser Rx Tablet and Capsule Counting Machine Edition v2.1

EC DECLARATION OF CONFORMITY

Compatibility of equipment design & manufacturing standards to current acceptable European

community CE marking standards.

C.E.King Limited hereby declare that the following machine complies with the essential health

and safety requirements of the Machinery Directive 2006/42/EC, (Formally 98/37/EC replacing

89/392/EEC) and its amendments (93/68/EEC, 93/44/EEC and 91/386/EEC), the Low Voltage

Directive 2006/95/EC (Formally 73/23/EEC) and its amendment (93/68/EEC), the requirements of

the Electromagnetic Compatibility Directive 2004/108/EC (Formally 89/336/EEC) and its

amendments (93/68/EEC and 92/31/EC)

Machine Model: Dispenser RX

Description: Electronic Tabletop Tablet and Capsule Counting Machine

Serial Number: 5780/14

The following transposed harmonised European standards have been used:

BS EN ISO 12100:2010 - Safety of Machinery - Safety of machinery. General principles for design.

Risk assessment and risk reduction.

BS EN ISO 13857:2008 - Safety of machinery. Safety distances to prevent hazard zones being

reached by upper and lower limbs.

BS EN 349:1993+A1:2008 - Safety of Machinery - Minimum gaps to avoid crushing parts of the

human body.

BS EN ISO 13850:2015 - Safety of Machinery - Emergency stop function. Principles of design.

BS EN 60204-1:2006+A1:2009 - Safety of Machinery - Electrical equipment of machines. General

requirements.

BS EN 61000-6-4:2007+A1:2011 - EMC, Generic Standards. Emission standard for Industrial

Environments

BS EN 61000-6-2:2005 - EMC, Generic Standard, Immunity for Industrial Environments

In addition, this machine has been designed and manufactured in accordance with British Standard

PD 5304:2014 - Guidance of Safe Use of Machinery

A technical construction file for this machinery is retained at the following address:

C.E.King Limited

3000 Hillswood Drive

Hillswood Business Park

Chertsey

Surrey

KT16 0RS

United Kingdom

Signature…………………………………..

Name………………………………………..

Position…………………………………….