8 User Instruction ManualKingspan SafePro 2

Anchor and Cable System

5.1 Inspection and General Maintenance

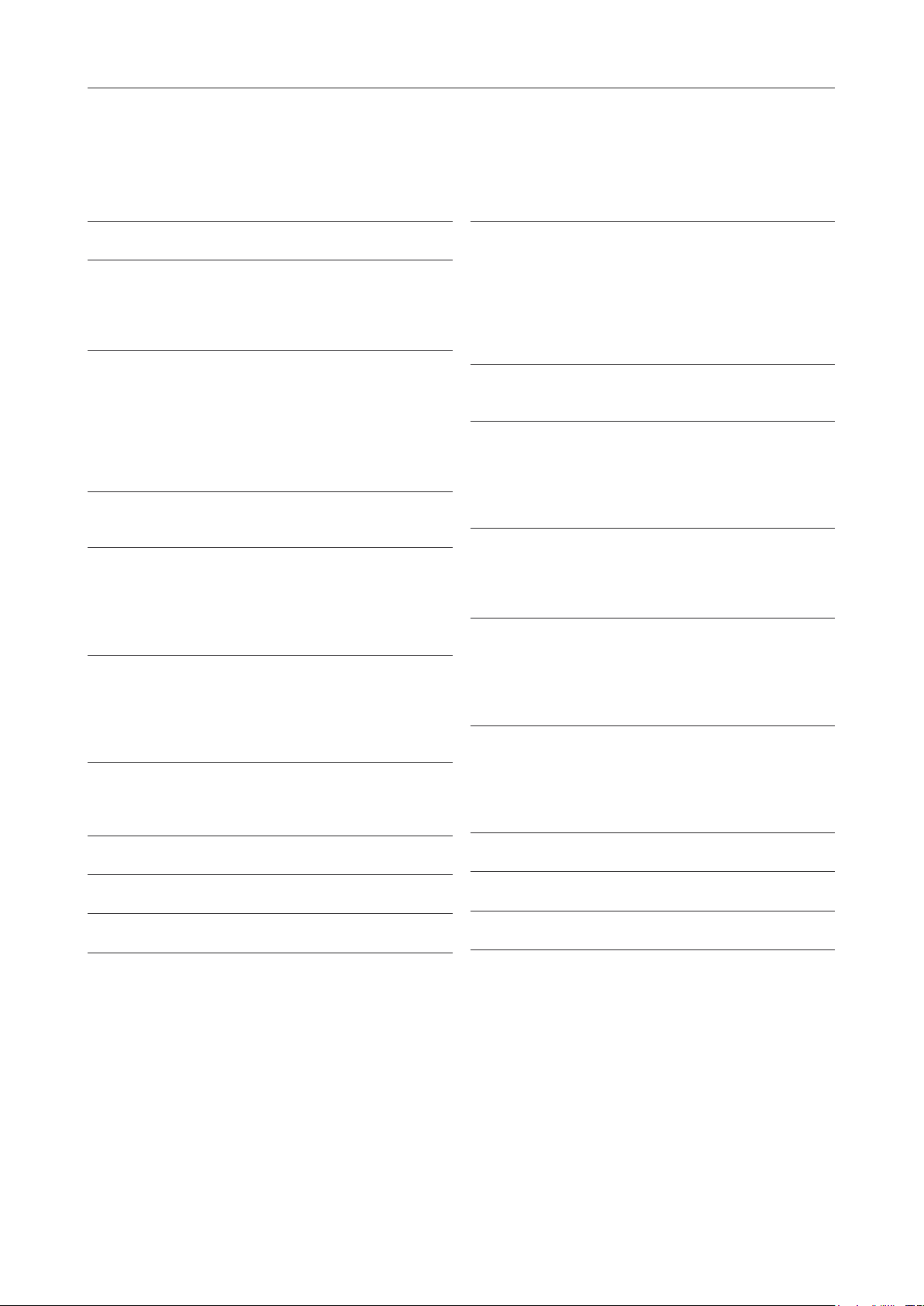

The Kingspan SafePro 2 Anchor has been designed to be used

under a variety of conditions. It uses high-grade components

that are corrosion resistant. However, the Anchors working life

depends on factors such as correct care and maintenance and

the environment in which the system is installed. Before each

occasion of use a visual check must be conducted to ensure the

Anchor is fit for purpose.

The Anchor attachment eye should be free to rotate and all the

fixing should be firmly secure. If the anchor is bent or deformed

in a way which is uncharacteristic of the Anchor you should not

use it. Report the faults to the Kingspan Certified Installer and

schedule a maintenance visit.

DO NOT attempt to repair the Anchor(s) yourself, as this may

invalidate performance warranties and put personnel in danger.

The SafePro 2 Anchor is virtually maintenance free dependent

on environment. Occasionally the Anchor may need cleaning.

This should be done with a soft brush, warm water and a

mild detergent. Ensure the parts are thoroughly rinsed with

plenty of clean water. Although highly resistant to chemicals

and environmental conditions, take all precautions to avoid

contaminating the Anchor(s) with acids, bitumen, cement,

chloride, paint or aggressive cleaning fluids.

Stainless Steel parts are particularly susceptible to pitting

corrosion from chlorine, so avoid exposure in this type of

environment.

If the system is likely to be contaminated, please contact your

Kingspan Certified Installer or Kingspan for advice.

5.0 Inspection, Maintenance, Servicing &

Warranty

5.2 Servicing

In accordance with manufacturers recommendations and

current national standards, an Anchor that is in regular use

should be inspected at least once a year by a Certified Kingspan

Installer. In very high use applications or aggressive environments

the servicing interval should be more frequent as determined

by the installer. The Anchor(s) is unlike other anchorages and

has many unique features, therefore only Certified Kingspan

Installers who have been trained and certified should inspect this

product.

A maintenance checklist is provided to our trained installers to

use during annual inspections. Please see Section 9.0 in this

manual.

If the Anchor(s) has sustained a fall arrest impact, has been

damaged, or is defective in any way, it must be immediately

categorised as unfit for use. The use of the system must be

discontinued, and servicing should be arranged as soon as

possible. All servicing requirements should be directed to

Kingspan or their Certified Installer.

5.3 Warranty

Full details of the warranty terms and exclusions are available

under the SafePro 2 Cable System warranty, which is available as

a separate document.