K115sm1e1.doc

1-3

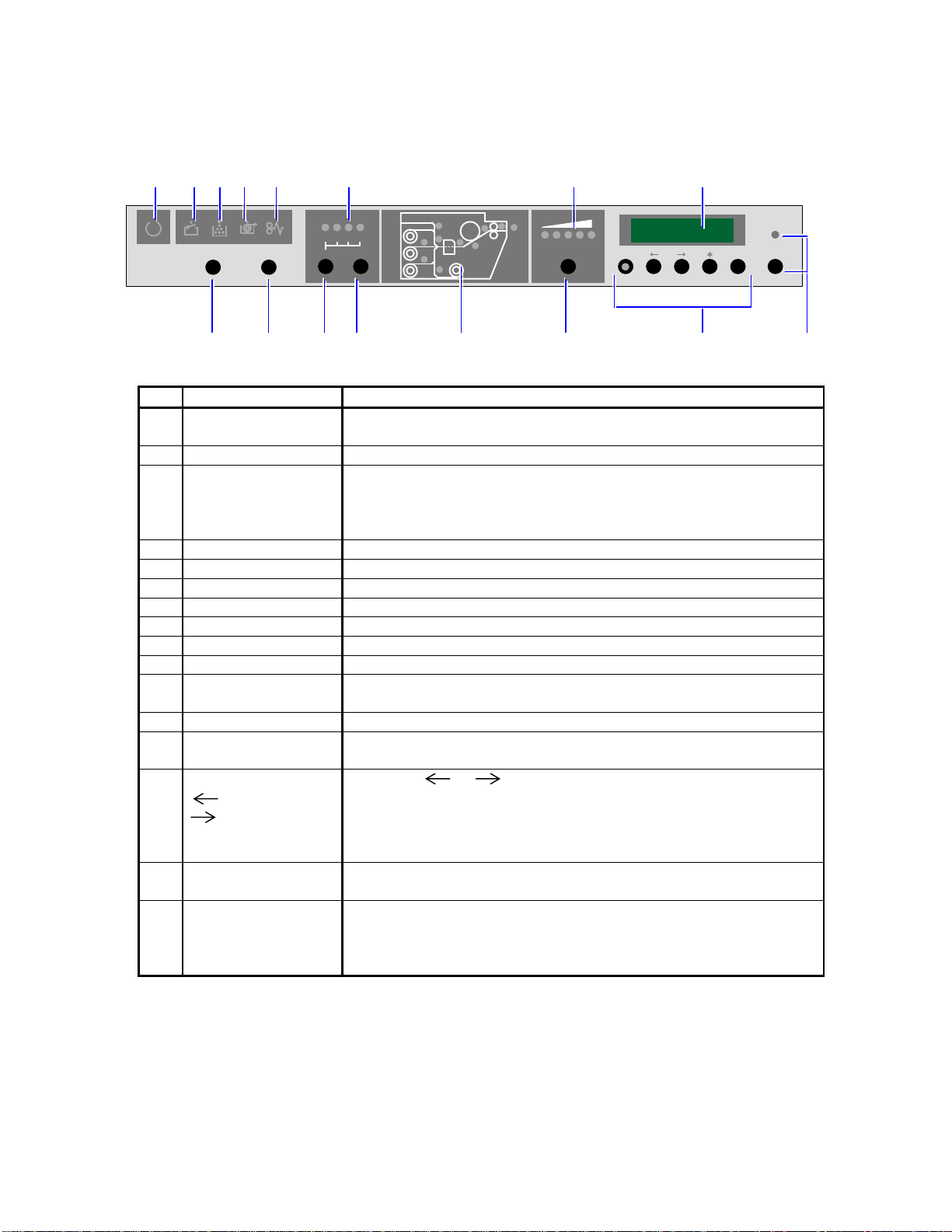

1. 2 Specifications

Subject Specification

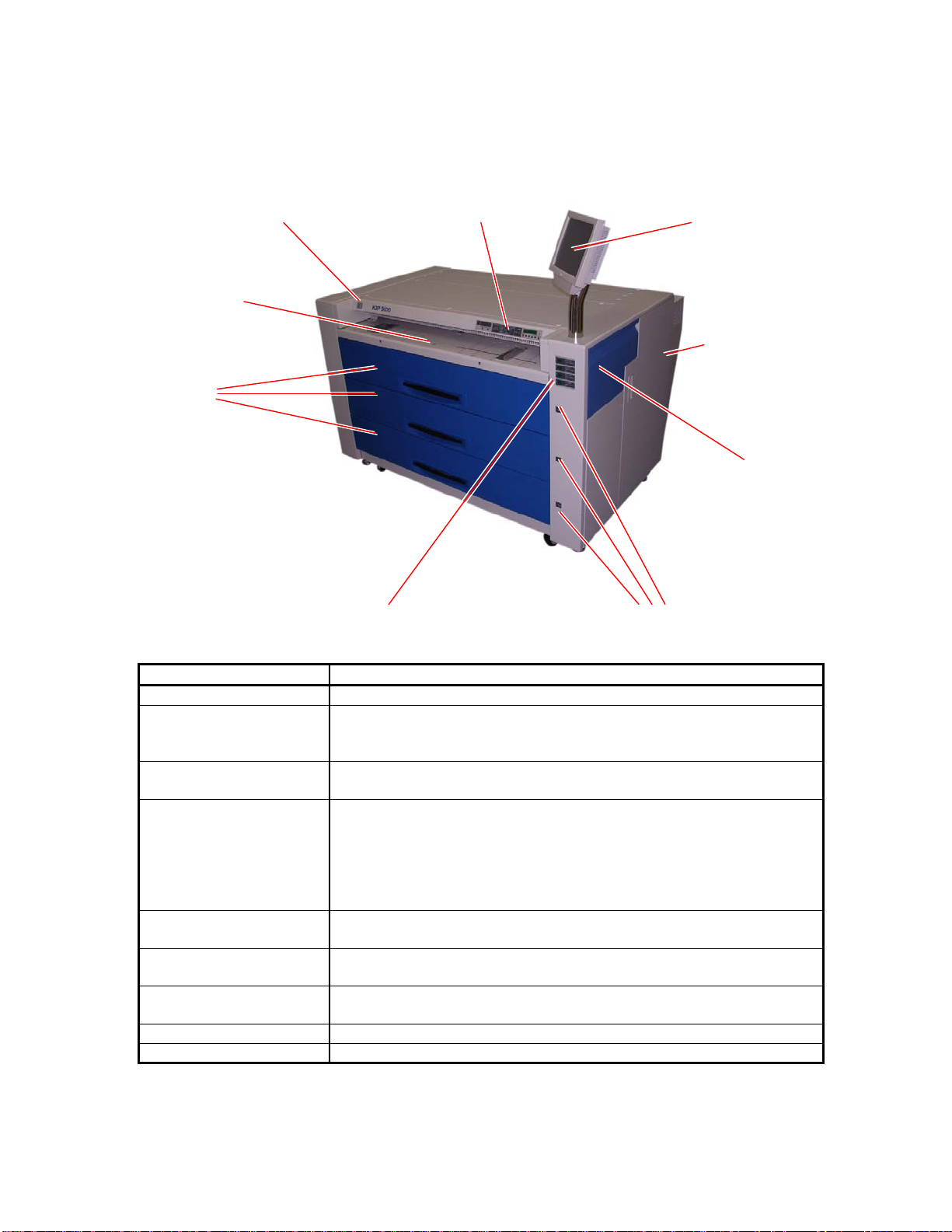

Model KIP 9000

Type Console

Printing method LED Array Electro Photography

Photoconductor Organic Photoconductive Drum

Print speed 240mm / second (11 A0 or E /minute - 22D/minute)

Exposure method LED Print Head

Resolution 600dpi x 600dpi

Print width Max : 914mm (36 inches)

Min : 297mm (11 inches)

Print length Max : Plain paper 6m (19.7’) with A0 or 36” wide

Tracing paper A0 / 48 inch

Film A0 / 48 inch

NOTE : Longer print than the above specified maximum lengths

is available. However, KIP does not guarantee any result

including image quality and media feeding if the print is

longer than the above specified lengths.

Min 210mm (8.5”)

Warm up time Shorter than 6 minutes

(At 23 degrees centigrade, 60% RH and 230V)

First print time Shorter than 12 seconds (A0 / E)

Fusing method Heat roller fusing

Development Contact type mono component non-magnetic development system

(One toner cartridge contains 500g.)

Charging method Corona

Media feeding method Automatic roll feeding (4 Roll Decks)

Manual bypass feeding

NOTE : Multiple cut sheet feeding (50 sheets max) is available

when the size is narrower than A2 (594mm) or 24”.

Transfer method Corona

Separation method Corona and LED

Input power 220 - 240V (+6% / -10%), 16A and 50/60Hz in U.S.A. and Europe

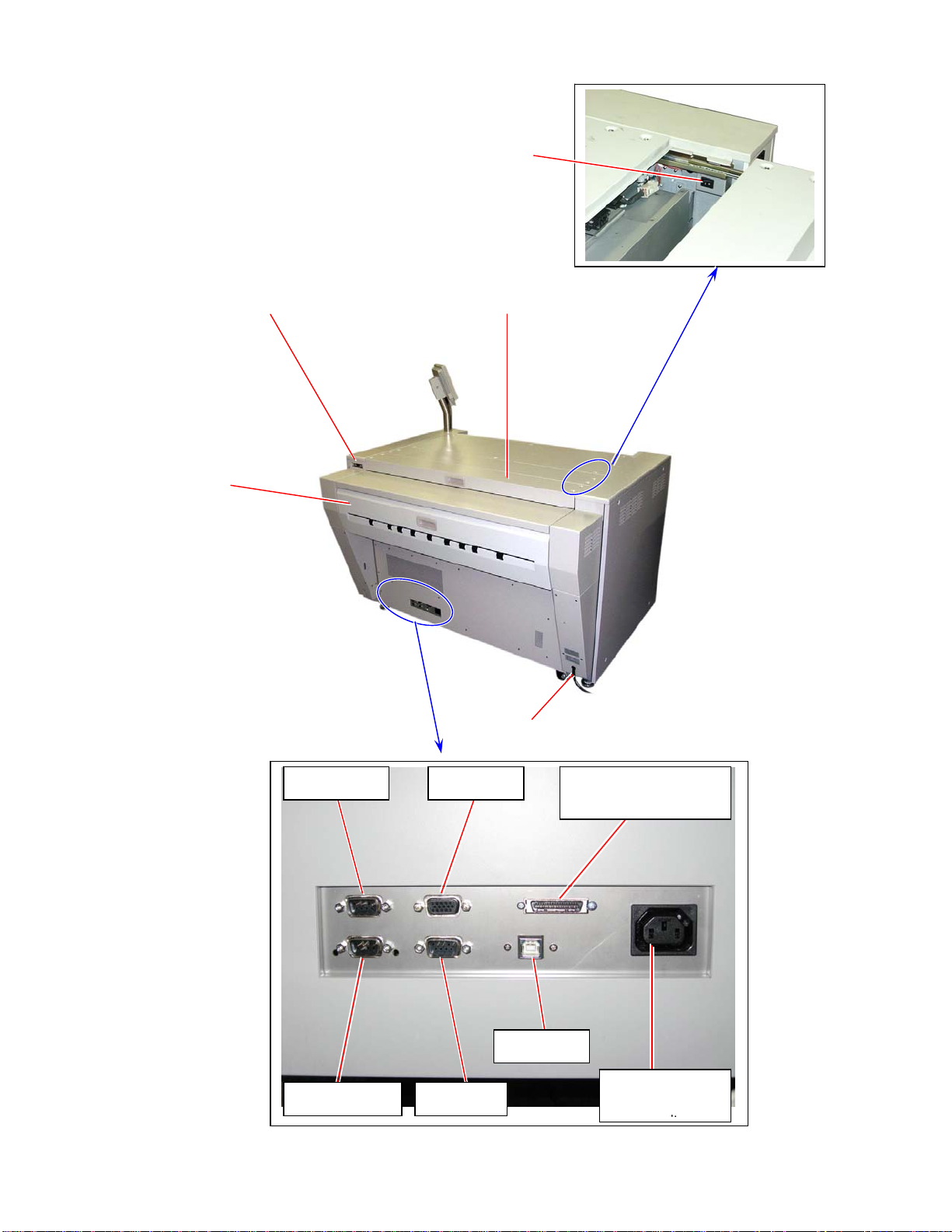

Interface KIP Interface 8 (LVDS)

USB2.0 (5VDC max)

RS-232C (12VDC max)

Maximum power

consumption When 230V, 50/60Hz and Dehumidify Heater is ON

Stand by 0.9 Kwh

Printing 3.0 Kwh

Warm up 3.5 Kwh

Acoustic noise Less than 70db (Printing) NOTE : Impact noise is excluded.

Less than 55db (Stand by)

Ozone Less than 0.05ppm (Average of 8 hours)

Dimensions 1360mm (Width) x 980mm (Depth) x 1265mm (Height) (54x39x50)

Weight About 400kg (880lbs)

Media Specified media

Plain paper 18 - 24# 70 - 90g/m2

Tracing paper 18 - 24# 70 - 90g/m2

Film 100 micrometer (4mil) or thinner..