Kirby Morgan One Way Valve User manual

Other Kirby Morgan Diving Instrument manuals

Kirby Morgan

Kirby Morgan M-48 SuperMask User manual

Kirby Morgan

Kirby Morgan M-48 MOD-1 User manual

Kirby Morgan

Kirby Morgan SuperLite 27 User manual

Kirby Morgan

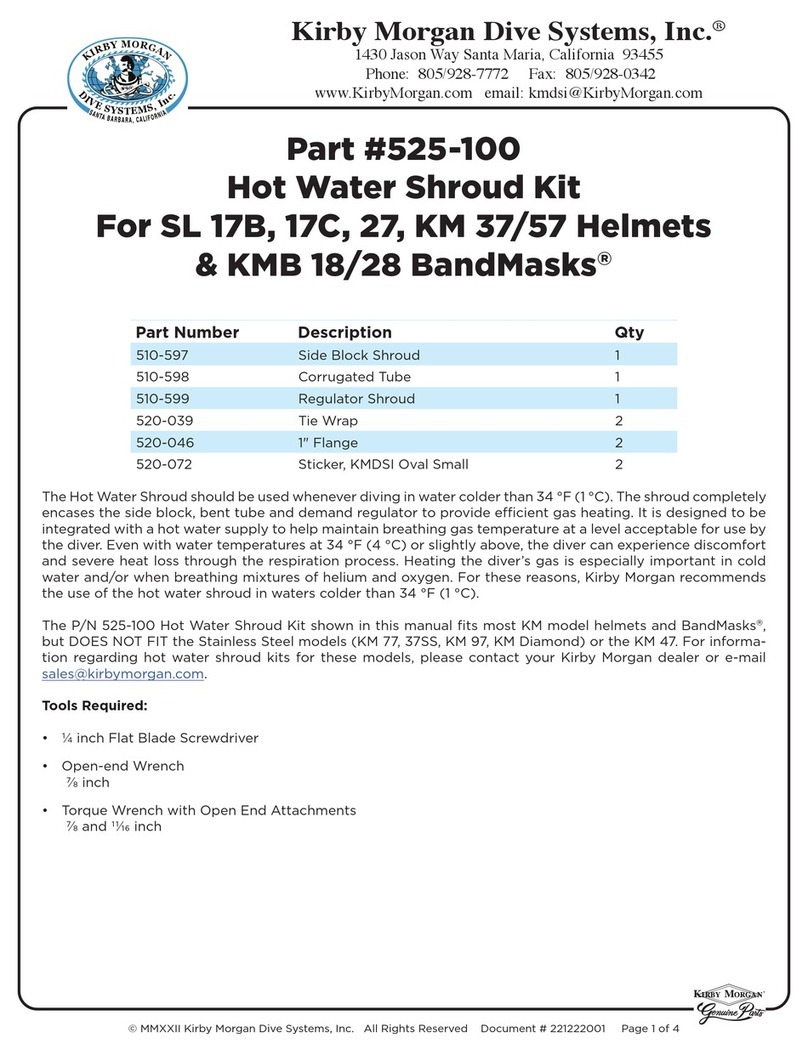

Kirby Morgan 525-100 User manual

Kirby Morgan

Kirby Morgan 17A/B User manual

Kirby Morgan

Kirby Morgan MOD-1 User manual

Kirby Morgan

Kirby Morgan 37 User manual

Kirby Morgan

Kirby Morgan KMB 18 Operating instructions

Kirby Morgan

Kirby Morgan EXO Full-Face Mask Manual

Kirby Morgan

Kirby Morgan EXO original Manual

Kirby Morgan

Kirby Morgan KM 97 User manual

Kirby Morgan

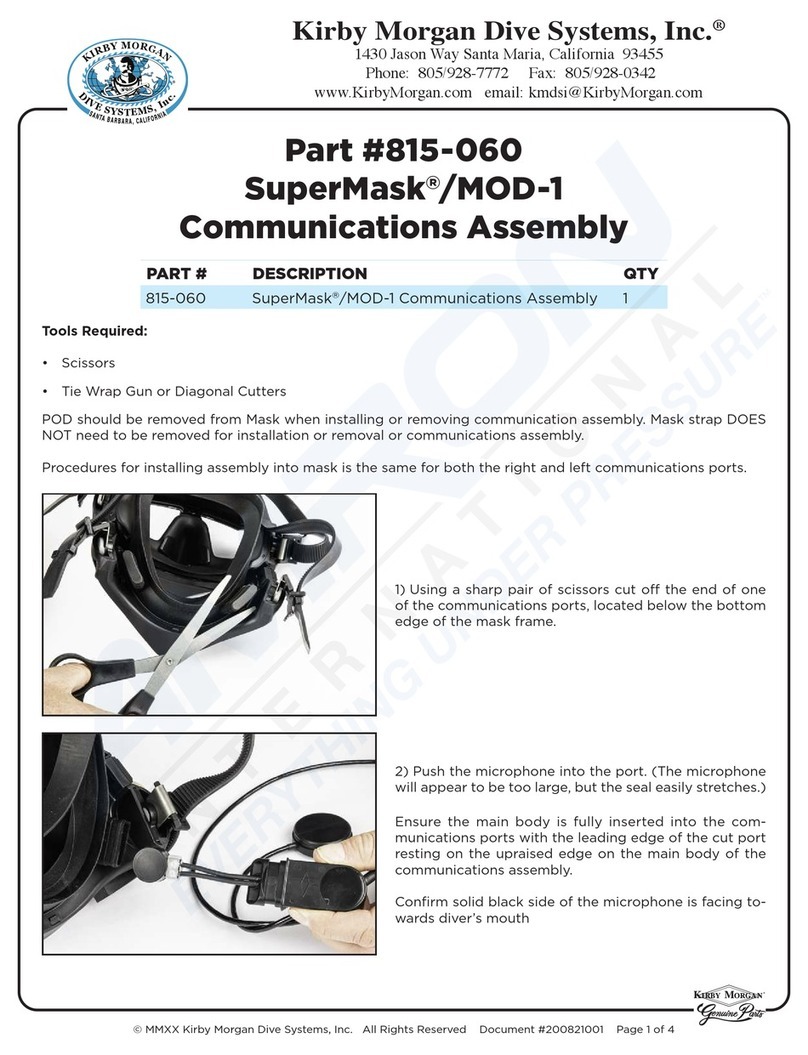

Kirby Morgan SuperMask MOD-1 User manual

Kirby Morgan

Kirby Morgan 525-769 User manual

Kirby Morgan

Kirby Morgan 37SS User manual

Kirby Morgan

Kirby Morgan SuperLite 27 User manual

Kirby Morgan

Kirby Morgan SuperLite 17C Helmet User manual

Kirby Morgan

Kirby Morgan SuperFlow 525-757 User manual

Kirby Morgan

Kirby Morgan M-48 MOD-1 User manual

Kirby Morgan

Kirby Morgan M-48 SuperMask User manual

Kirby Morgan

Kirby Morgan 77 User manual