KIRLOSKAR RKB Programming manual

Other KIRLOSKAR Water Pump manuals

KIRLOSKAR

KIRLOSKAR KPDS Programming manual

KIRLOSKAR

KIRLOSKAR DB 32/13 Installation and operating instructions

KIRLOSKAR

KIRLOSKAR RKB Programming manual

KIRLOSKAR

KIRLOSKAR KOSN Series Instruction manual

KIRLOSKAR

KIRLOSKAR CPHM Programming manual

KIRLOSKAR

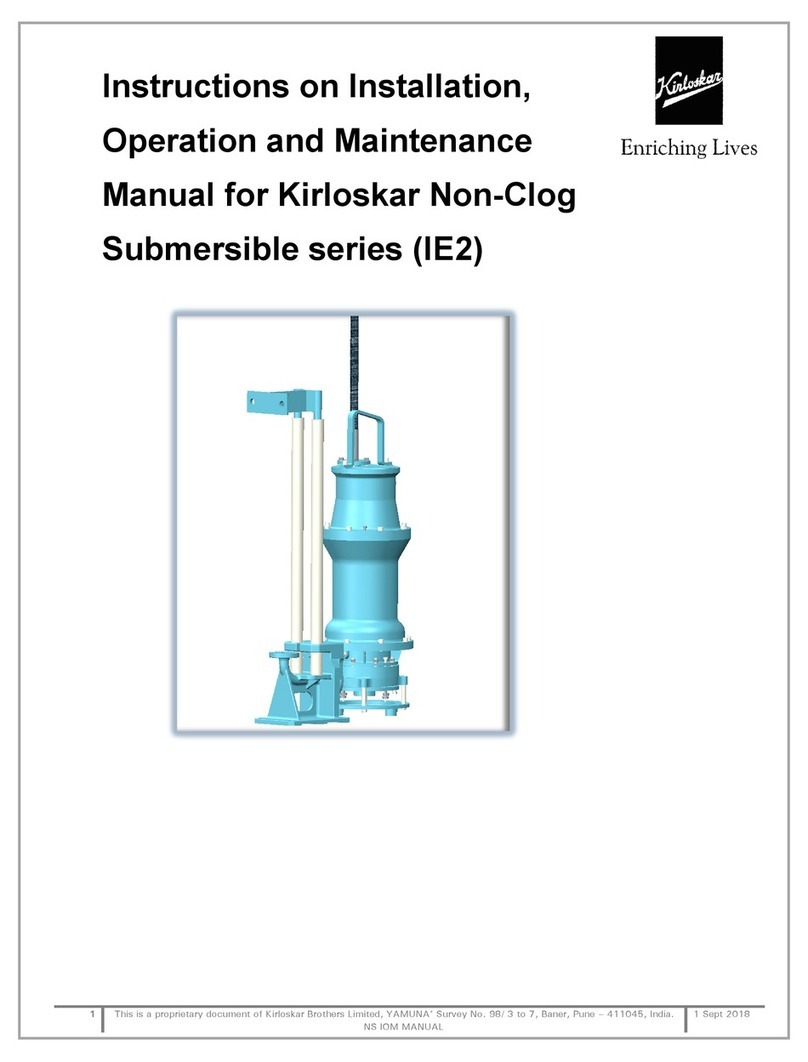

KIRLOSKAR Non-Clog Submersible Series Programming manual

KIRLOSKAR

KIRLOSKAR i-HT Programming manual

KIRLOSKAR

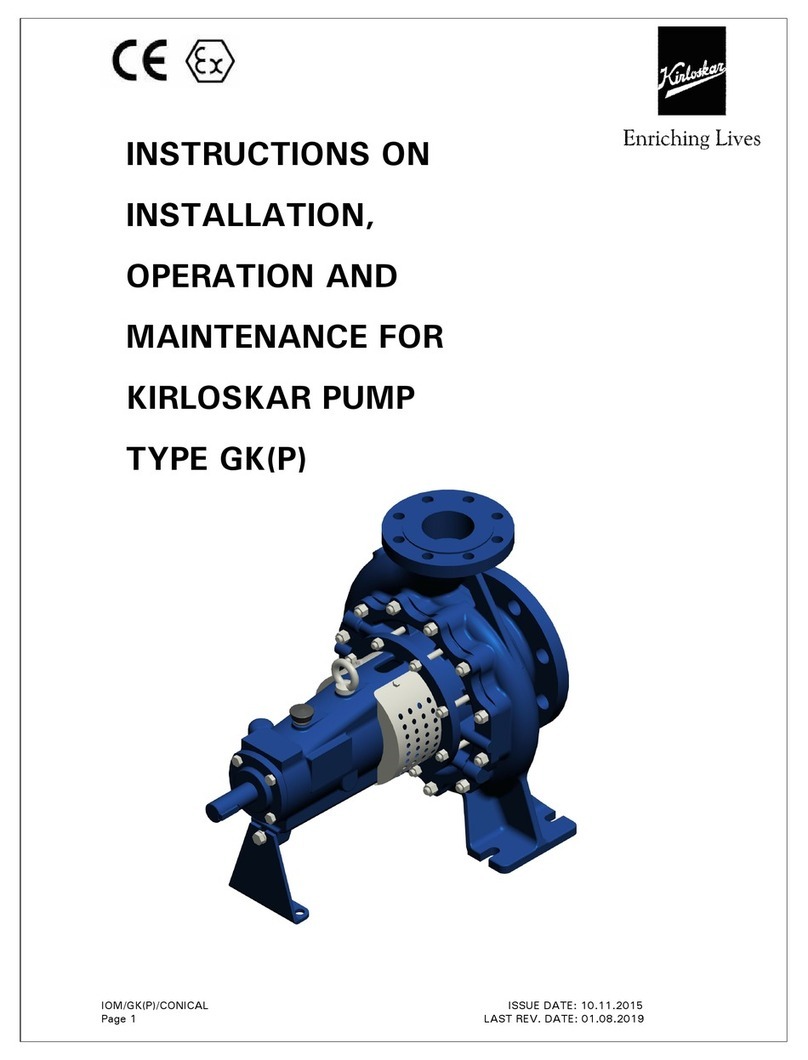

KIRLOSKAR GK Series Programming manual

KIRLOSKAR

KIRLOSKAR HSC LLC User manual

KIRLOSKAR

KIRLOSKAR DSM Series Programming manual

KIRLOSKAR

KIRLOSKAR i-CM32/13-0.75kW/2P User manual

KIRLOSKAR

KIRLOSKAR Non Clog NS Series Programming manual

KIRLOSKAR

KIRLOSKAR CF Series Programming manual

KIRLOSKAR

KIRLOSKAR SHS Programming manual

KIRLOSKAR

KIRLOSKAR GOLD JALSENA User manual

KIRLOSKAR

KIRLOSKAR RKBV Programming manual

KIRLOSKAR

KIRLOSKAR IN 40/160 IL Programming manual

KIRLOSKAR

KIRLOSKAR GK Series Programming manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual