9

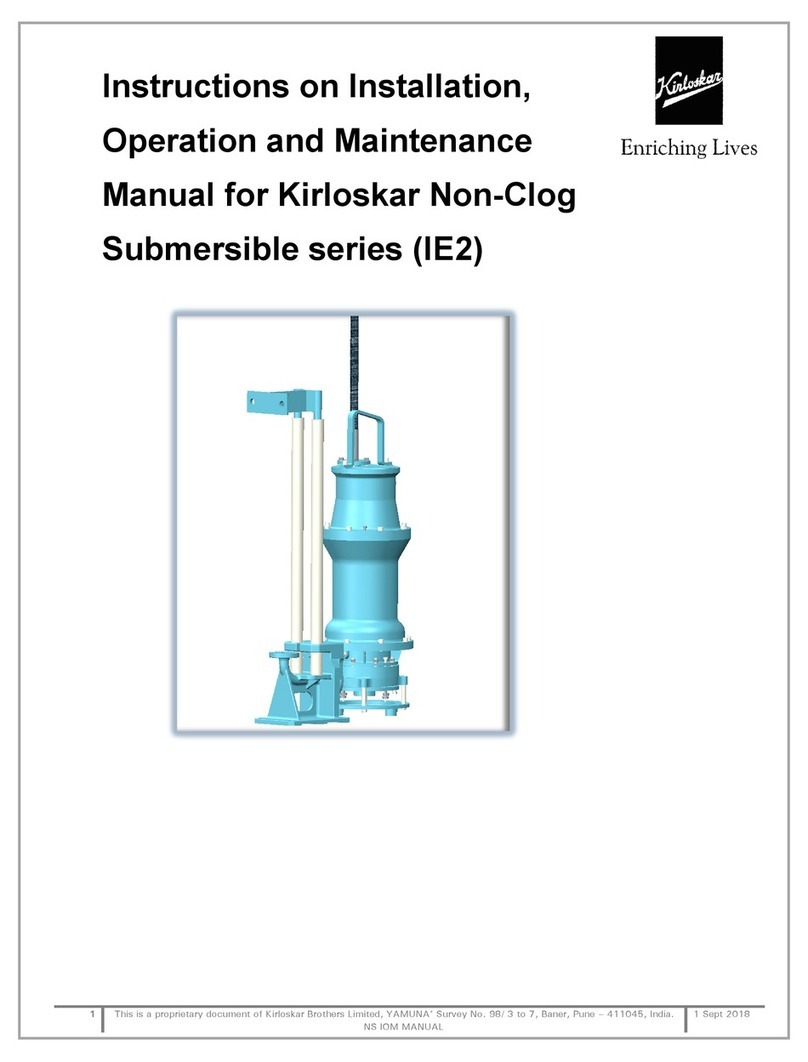

This is a proprietary document of Kirloskar Brothers Limited, Kirloskarvadi

3.1.3

Fix the guide pipe in the support bracket and locate the vertical position of guide pipe holder at

the top of the pit. Now the grout the guide pipe

3.1.4

Insert the above assembly in the guide pipe by dismantling the guide pipe holder & refit the holder

in the guide pipe.

3.1.5 Check-

Lower the pump with the help of chain. While sliding over the guide pipe into the sump,

check that the cable is not slagg

3.1.6

Ensure that the pump position is exactly vertical on the support bracket. Check by giving a jerk.

3.1.7

Before taking the pumping station into use, check that there are no loose solid pieces or other

material on bottom of sump tha

3.1.8

DO NOT LIFT THE PUMP WITH THE HELP OF CABLES.

3.2

The NS pumps supplied for

delivery pipe line is well supported and its weight is not acting on pump casing direct

3.3

Use chain with intermediate hooks for holding to lower or lift the pump. This type of chain is

specially design to avoid the tendency of the operator to lift the pump with the help of cable

causing damage & replacement of the cable unit. While selecti

the pump given in chart (6). and chain capacity as per below chart (2)We recommend use of non

return valve in delivery pipe line located before sluice valve.

3.1.1

As per IS: 2429 the following sizes of chains can be used

mentioned in the below chart

4. OPERATION :

4.1

Prior to commissioning of the pump, check the following.

FILL THE OIL INSIDE THE MECHANICAL SEAL HO

(5) OF CLEAN OIL FREE FROM MOISTURE. ENSURE THE MECHANICAL SEAL HOUSING OF THE

PUMP IS DULY FILLED AS PER CHART NO. (6). CHECK THE OIL PLUG OF THE MECHANICAL SEAL

HOUSING IS INTACT.

4.1.1

Check the insulation resistance of

winding should not be less than 10 mega

beyond 45kW at phase to phase and phase to Earth. This test should be carried out at free end of

the cable

. If the insulation resistance is found less than mentioned above then please consult our

service personnel.

For continuity test, connect the two wires of megger between the two ends of the same phase of

motor. It should show zero resistance. This test sh

The resistance across two moisture sensing wires M1 and M2 should be above 5 M

to remove control cable connections from terminal board [M1 and M2] before testing this. If the

resistance found less, please co

phase and phase to Earth should be conducted serially. The megger test should show insulation

resistance above 10 MΩ

for motor rating upto 45kW and 50 M

This is a proprietary document of Kirloskar Brothers Limited, Kirloskarvadi

NS IOM MANUAL

Fix the guide pipe in the support bracket and locate the vertical position of guide pipe holder at

the top of the pit. Now the grout the guide pipe

holder.

Insert the above assembly in the guide pipe by dismantling the guide pipe holder & refit the holder

Lower the pump with the help of chain. While sliding over the guide pipe into the sump,

check that the cable is not slagg

ing and is not under tension.

Ensure that the pump position is exactly vertical on the support bracket. Check by giving a jerk.

Before taking the pumping station into use, check that there are no loose solid pieces or other

material on bottom of sump tha

t would damage the pump.

DO NOT LIFT THE PUMP WITH THE HELP OF CABLES.

The NS pumps supplied for

portable installation

requires no foundation. Only ensure that the

delivery pipe line is well supported and its weight is not acting on pump casing direct

Use chain with intermediate hooks for holding to lower or lift the pump. This type of chain is

specially design to avoid the tendency of the operator to lift the pump with the help of cable

causing damage & replacement of the cable unit. While selecti

ng size of the chain, refer weight of

the pump given in chart (6). and chain capacity as per below chart (2)We recommend use of non

return valve in delivery pipe line located before sluice valve.

As per IS: 2429 the following sizes of chains can be used

mentioned in the below chart

.

Prior to commissioning of the pump, check the following.

FILL THE OIL INSIDE THE MECHANICAL SEAL HO

USING WITH PROPER GRADE REFER CHART

(5) OF CLEAN OIL FREE FROM MOISTURE. ENSURE THE MECHANICAL SEAL HOUSING OF THE

PUMP IS DULY FILLED AS PER CHART NO. (6). CHECK THE OIL PLUG OF THE MECHANICAL SEAL

Check the insulation resistance of

winding by using 500 V megger. The insulation resistance of

winding should not be less than 10 mega

-ohms for mot

or rating upto 45kW and 50 mega

beyond 45kW at phase to phase and phase to Earth. This test should be carried out at free end of

. If the insulation resistance is found less than mentioned above then please consult our

For continuity test, connect the two wires of megger between the two ends of the same phase of

motor. It should show zero resistance. This test sh

ould be carried out for the phases.

The resistance across two moisture sensing wires M1 and M2 should be above 5 M

to remove control cable connections from terminal board [M1 and M2] before testing this. If the

resistance found less, please co

nsult our service department. The megger test for phase to

phase and phase to Earth should be conducted serially. The megger test should show insulation

for motor rating upto 45kW and 50 M

Ωbeyond 45kW

.

Lifting capacity (Tonnes)

0.5

0.8

1.25

2.0

Fix the guide pipe in the support bracket and locate the vertical position of guide pipe holder at

Insert the above assembly in the guide pipe by dismantling the guide pipe holder & refit the holder

Lower the pump with the help of chain. While sliding over the guide pipe into the sump,

Ensure that the pump position is exactly vertical on the support bracket. Check by giving a jerk.

Before taking the pumping station into use, check that there are no loose solid pieces or other

requires no foundation. Only ensure that the

delivery pipe line is well supported and its weight is not acting on pump casing direct

ly.

Use chain with intermediate hooks for holding to lower or lift the pump. This type of chain is

specially design to avoid the tendency of the operator to lift the pump with the help of cable

ng size of the chain, refer weight of

the pump given in chart (6). and chain capacity as per below chart (2)We recommend use of non

-

USING WITH PROPER GRADE REFER CHART

(5) OF CLEAN OIL FREE FROM MOISTURE. ENSURE THE MECHANICAL SEAL HOUSING OF THE

PUMP IS DULY FILLED AS PER CHART NO. (6). CHECK THE OIL PLUG OF THE MECHANICAL SEAL

winding by using 500 V megger. The insulation resistance of

or rating upto 45kW and 50 mega

-ohms

beyond 45kW at phase to phase and phase to Earth. This test should be carried out at free end of

. If the insulation resistance is found less than mentioned above then please consult our

For continuity test, connect the two wires of megger between the two ends of the same phase of

ould be carried out for the phases.

The resistance across two moisture sensing wires M1 and M2 should be above 5 M

Ω. Make sure

to remove control cable connections from terminal board [M1 and M2] before testing this. If the

nsult our service department. The megger test for phase to

phase and phase to Earth should be conducted serially. The megger test should show insulation