03

TEFC (Totally Enclosed Fan-cooled) Motor

ü

Capacitor start and run motor (Single Phase).

ü

‘F’ Class of insulation.

ü

Specially processed steel shaft for corrosion resistance and durability

ü

Fitted with Thermal Overload Protector (TOP) for safety of motor.

ü

Both side double shielded ball bearings. No Need of external lubrication.

ü

Sturdy and rigid in construction.

ü

Aluminum extruded motor body for better heat dissipation and corrosion.

ü

Motor can withstand wide voltage fluctuations

ü

Keep strainer end at least one foot above the bottom of the well or tank.

ü

Suitable for use with clean water that does not contain abrasive particles and liquid that are not

ü

chemically aggressive towards the material from which the pump is made.

During cleaning of well or tank, do not suck residual muddy water through pump.

ü

Do not use any gate valve for throttling the delivery pipe, as this will result in overloading of the

ü

pump and subsequently burning of motor.

Do not run the pump dry to avoid the damage to mechanical seal.

ü

Read the operation manual carefully before installing the pump.

ü

Your pump is provided with broad based feet and hence does not require any special foundation

ü

for installation.

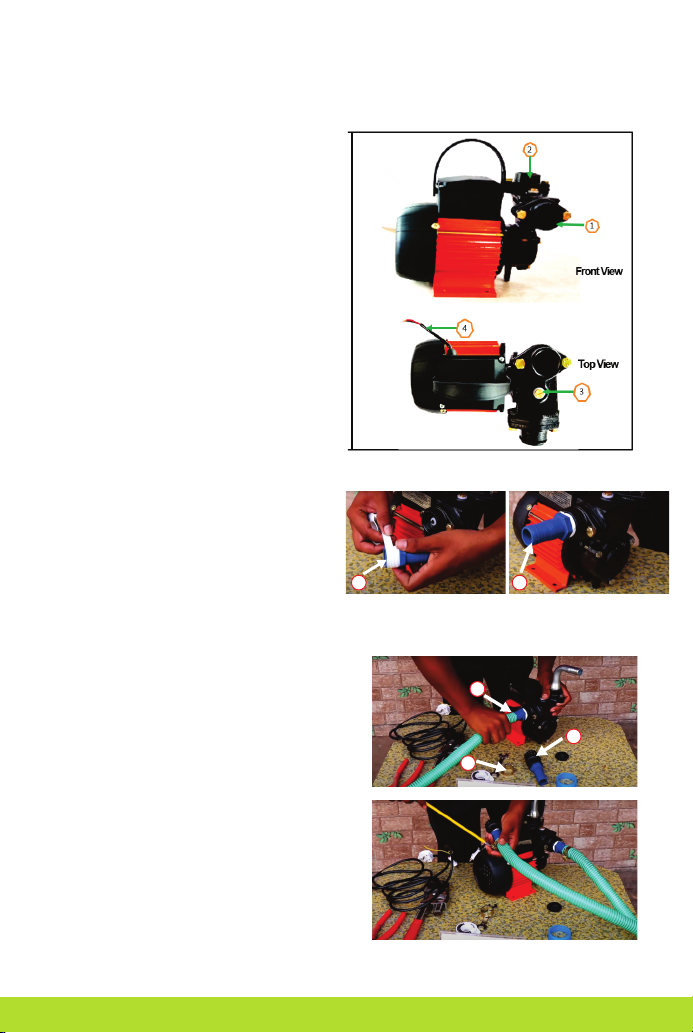

Use specified pipe size to get higher discharge.

ü

Though suction lift capacity of the pump is 7m, for more discharge keep suction lift as minimum as

ü

possible.

Ensure minimum number of BENDS and fittings in the pipeline. Ensure air tight joints.

ü

Use of additional foot valve is recommended for trouble free performance of pump.

ü

OR

Fit a correct size strainer at suction end so that no foreign matter (Hard particles) can enter the

ü

pump.

The horizontal length of the suction pipe should be straight. The pumpset must be installed in an

ü

enclosed environment or at least sheltered from inclement weather

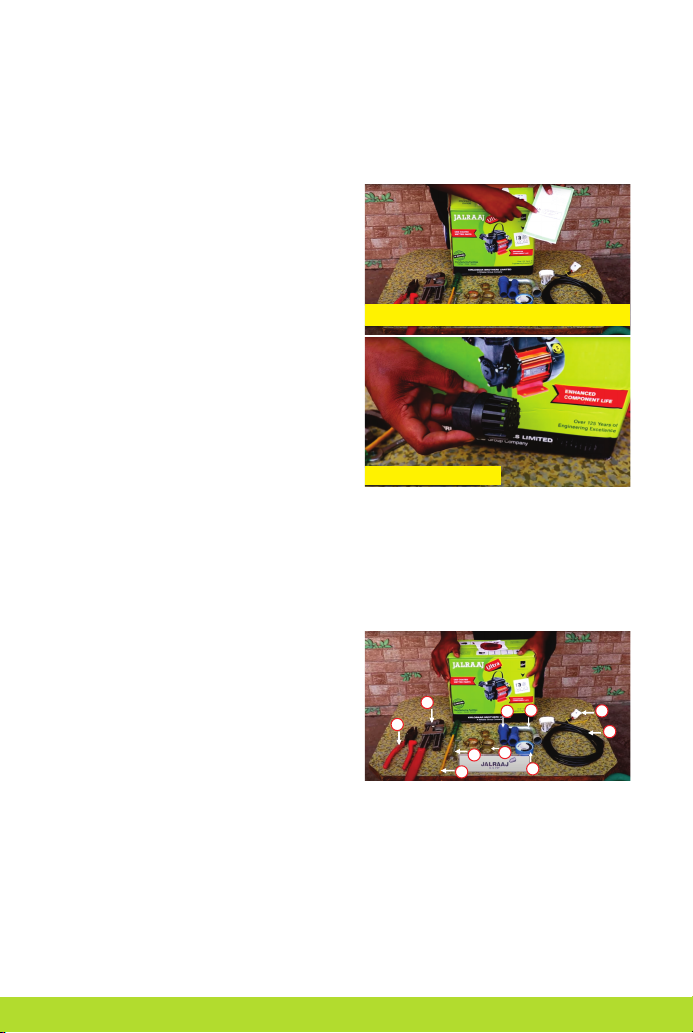

Installation & Use

Precautions

Features

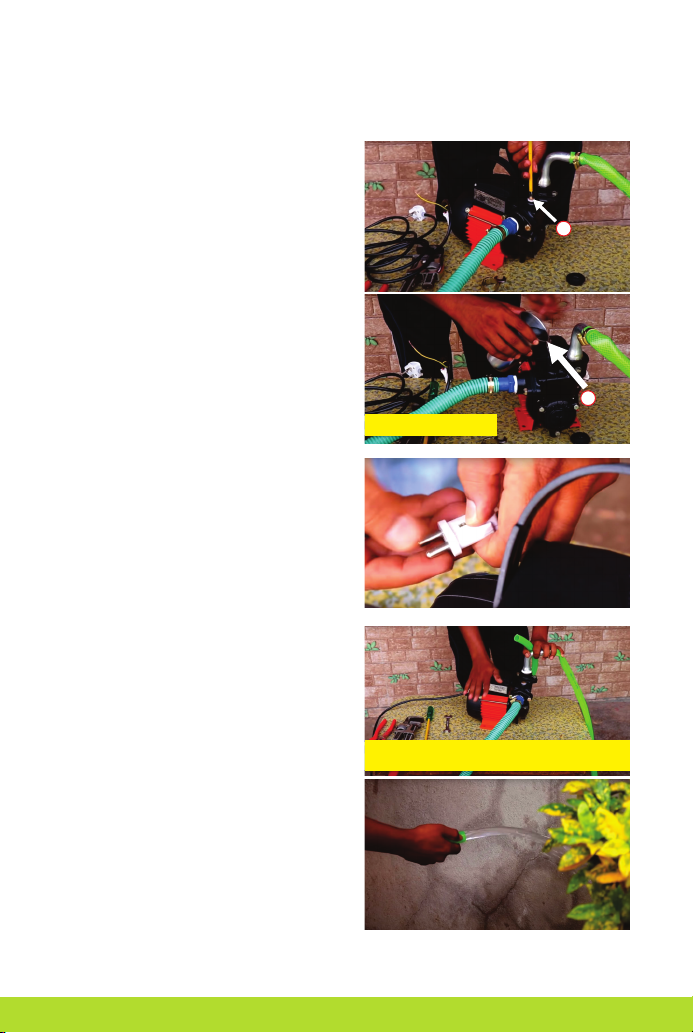

Before starting the pump for the first time, fill it with clean water.

ü

Check the freeness of shaft by rotating it with the help of a screw driver.

ü

A provision should be made in the delivery branch of the pump for easy priming. Open the priming

ü

plug / air vent nipple cock, fill water through the priming hole and tighten the plug. Now the pump

is ready for starting.

Ensure daily or alternate day running of the pump.

ü

If pump is to be kept idle for a long period, fill it fully with water or any other preservative.

ü

Periodically clean the strainer to avoid clogging.

ü

Do not wrap the pump with air tight material such as polythene bag to avoid condensation.

ü

Operation

Maintenance

Caution & Care

Power is switched off and unplugged.

ü

Electrical Connections are to be serviced only by qualified personnel.

ü

All parts are thoroughly cleaned in kerosene to remove the dirt and dust before re-assembly

ü

All parts are checked and replaced if damaged and worn out.

ü

Ensure that shaft rotates freely after assembly.

ü

During servicing or attending the pump, always ensure that: