4

INSTALLATION

INSTALLATION

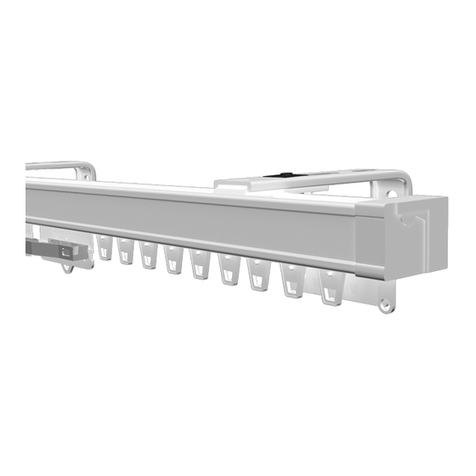

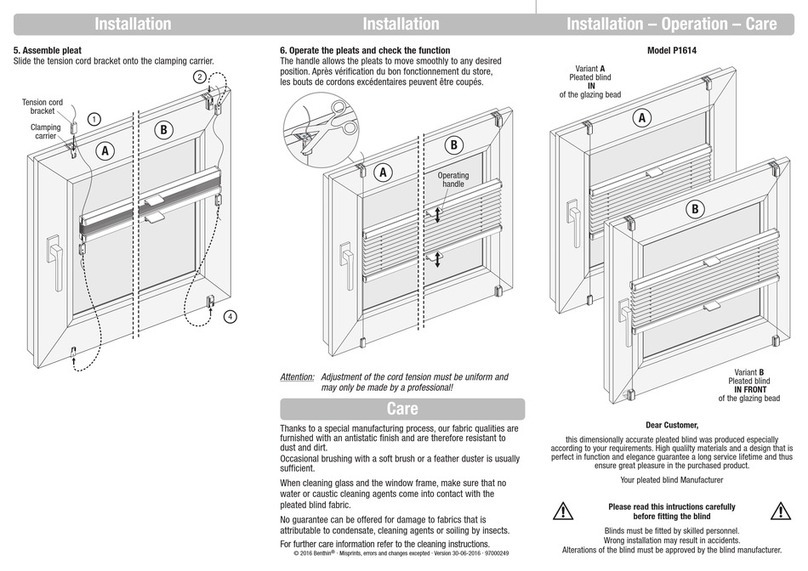

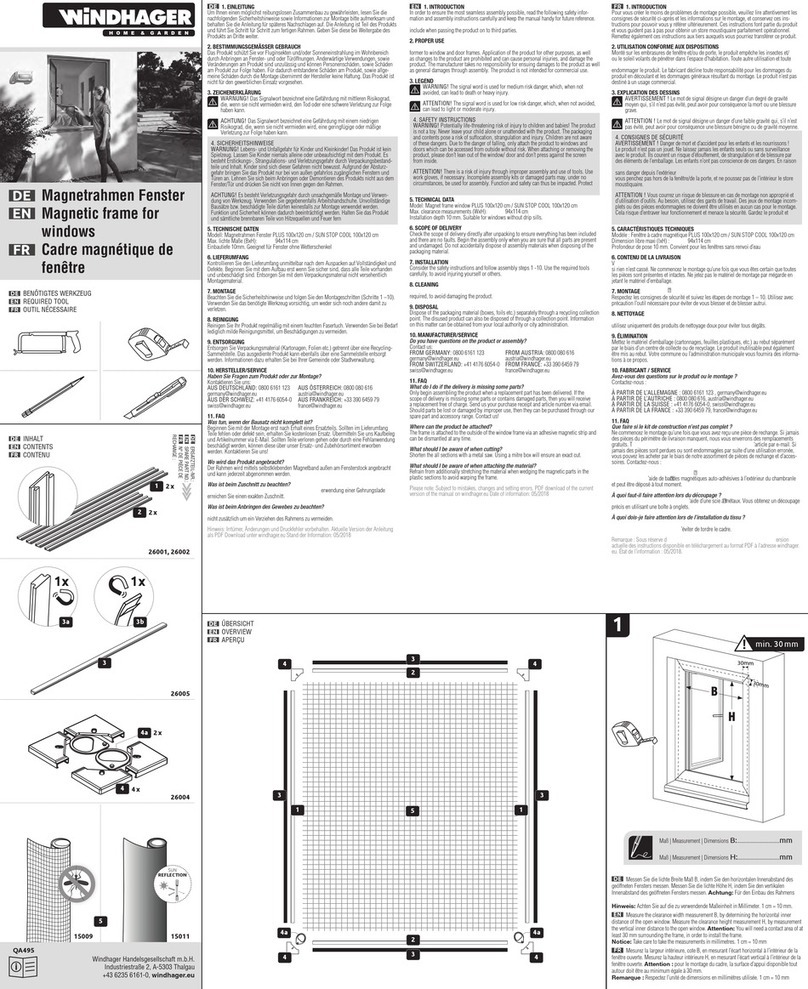

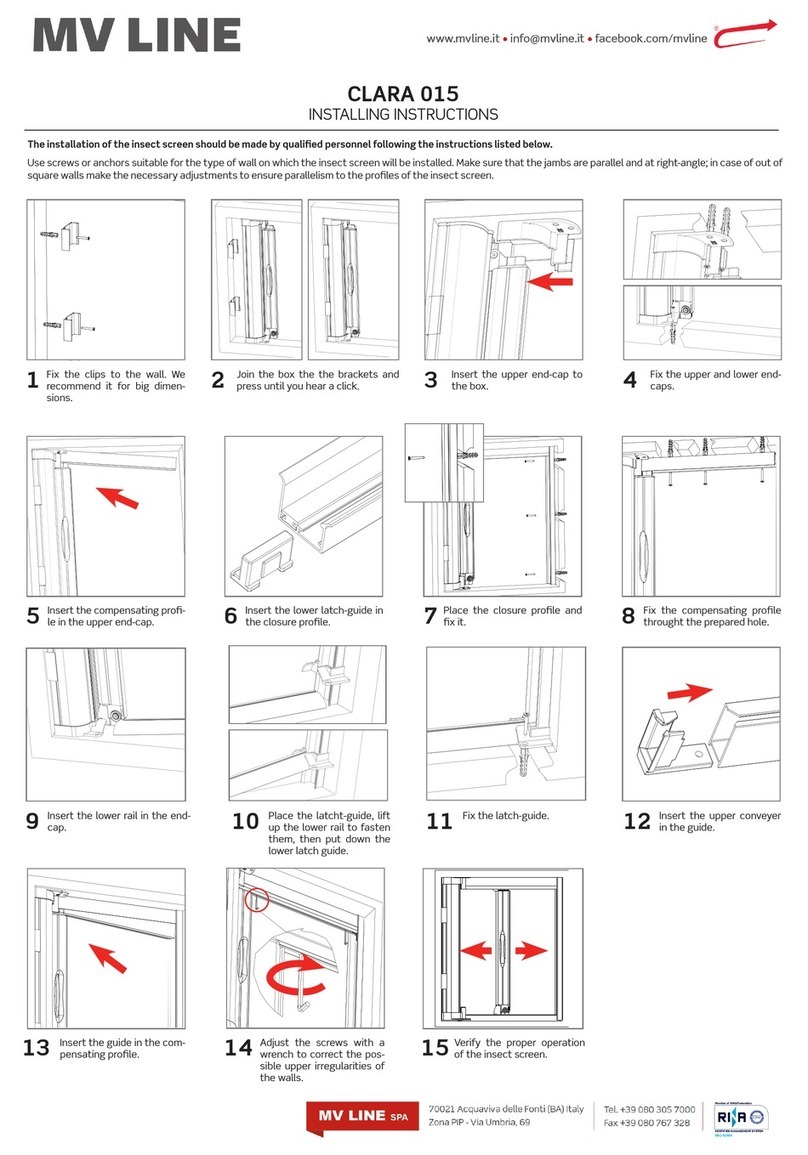

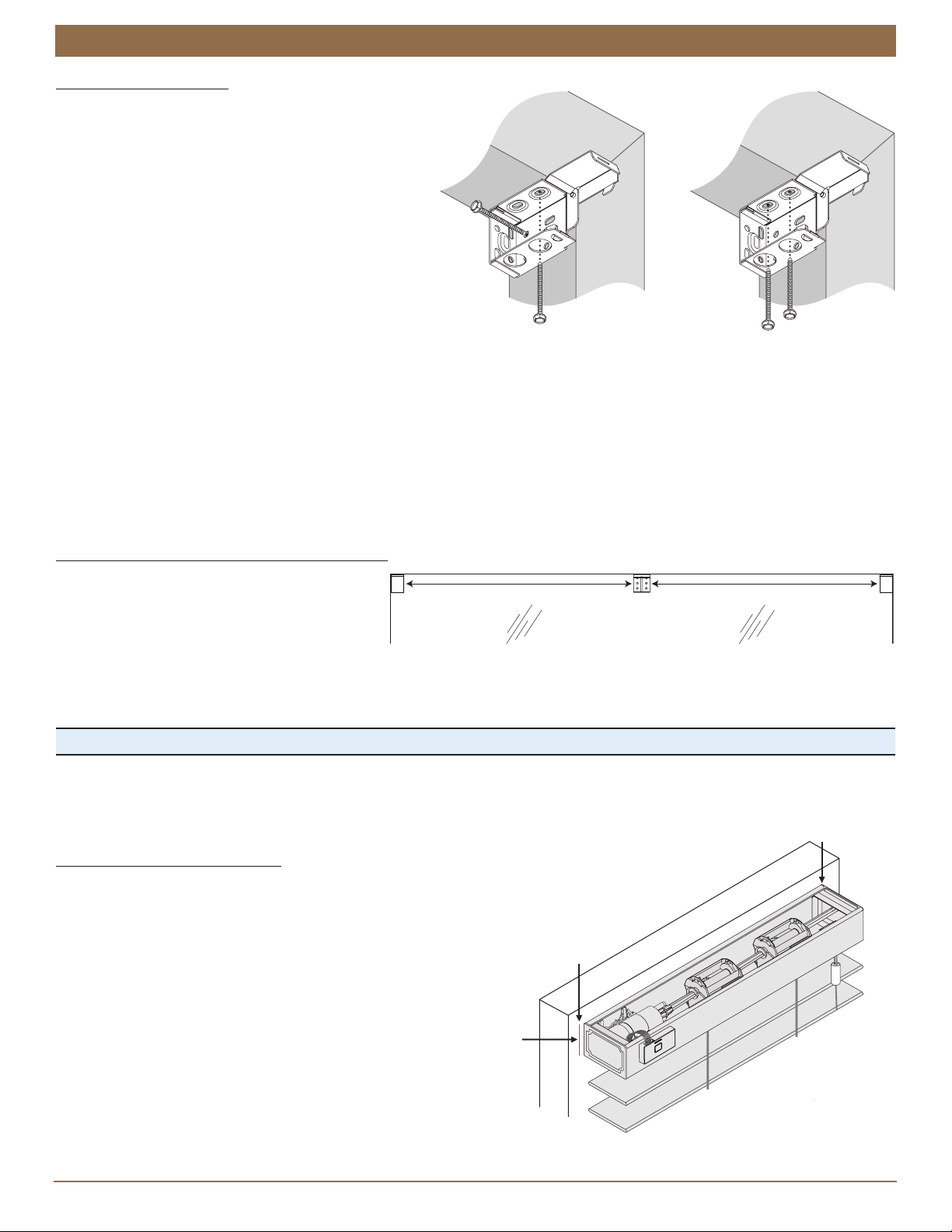

Attach the End Brackets

With inside or ceiling mounts, attach the two end brackets

flush against the sides of the window casement or to the

ceiling. Choose the most appropriate of the following

mounting methods:

Inside mount only (Side/Top Mount): Mount the end

brackets with one screw through a side hole and one

screw through a top hole, as shown in the first image

to the right.

Inside mount only (Side Mount): Mount the end

brackets with two screws through diagonal side holes.

Inside or ceiling mount (Top Mount): Top mount the

end brackets with screws through the two top holes, as

shown in the second image to the right.

Ceiling mount only: If the end brackets are flush with

the back wall, attach them with one screw through a

top hole and one screw through a rear hole.

Use a

3

⁄

32

" drill bit to drill holes for the mounting screws.

Attach the end brackets using the screws provided.

IMPORTANT: The front edges of the end brackets must align.

NOTE: For blinds with 2

1

⁄

2

" slats, spacer blocks are used with inside mounts to position the end brackets a minimum of

3

⁄

8

"

away from the glass. The spacing prevents the slats from rubbing the glass when they are tilted open.

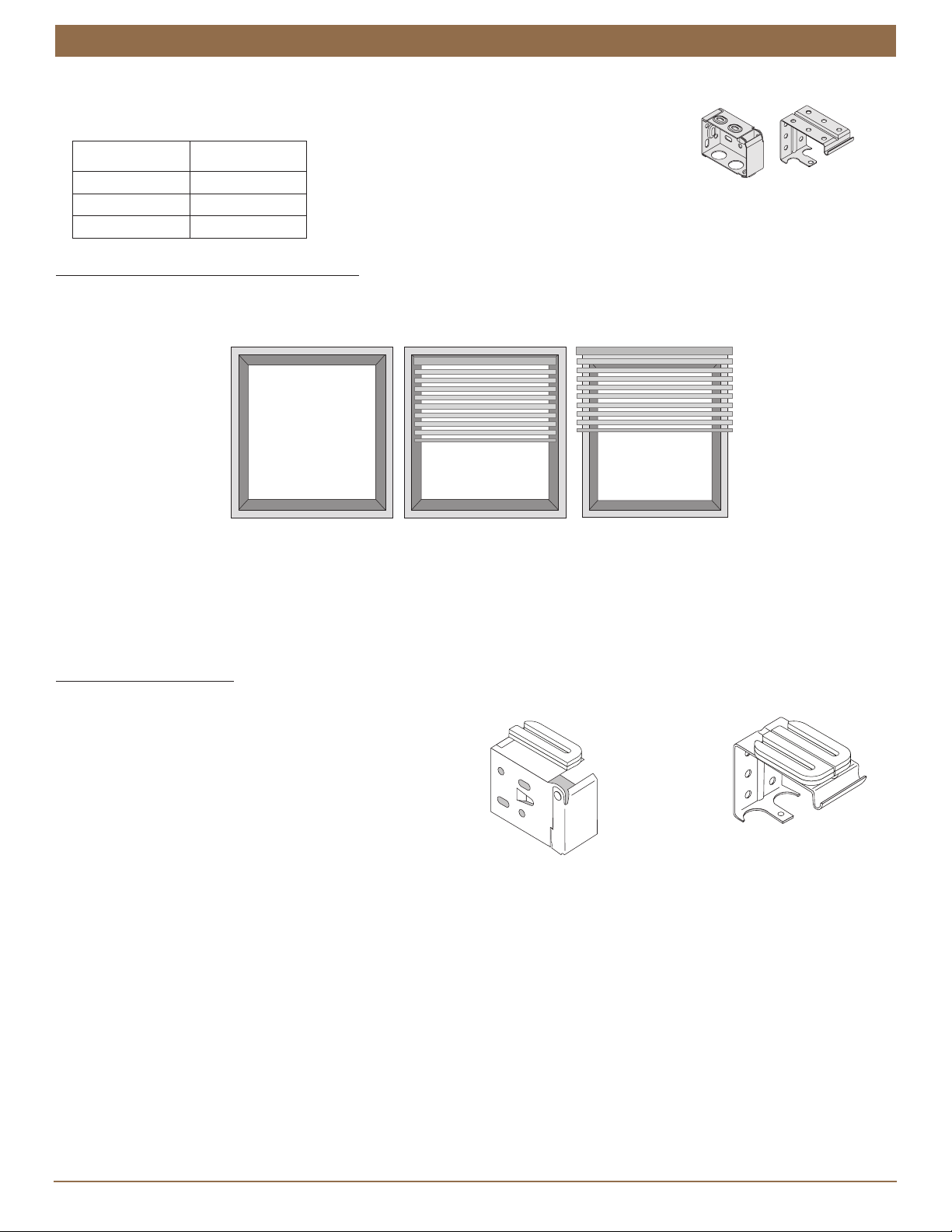

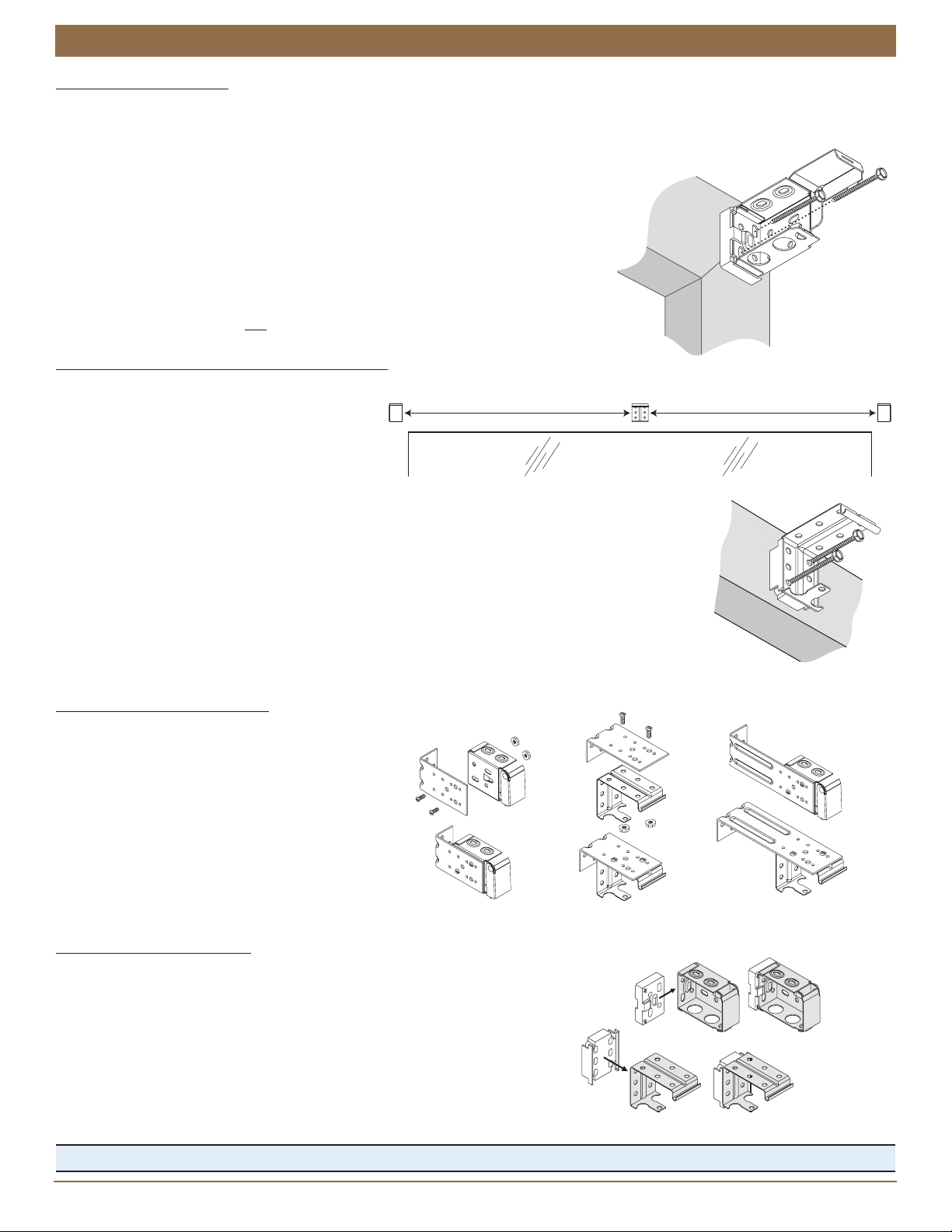

Attach the Intermediate Brackets (If Required)

Evenly space the intermediate bracket(s)

between the two end brackets.

Adjust spacing if needed to avoid

interference with internal headrail

mechanisms.

Attach the intermediate bracket(s) with two screws through diagonal top holes.

IMPORTANT: The rear of the end brackets and intermediate bracket(s) must align.

Proceed to “STEP 3 — Install the Blind” on page 6.

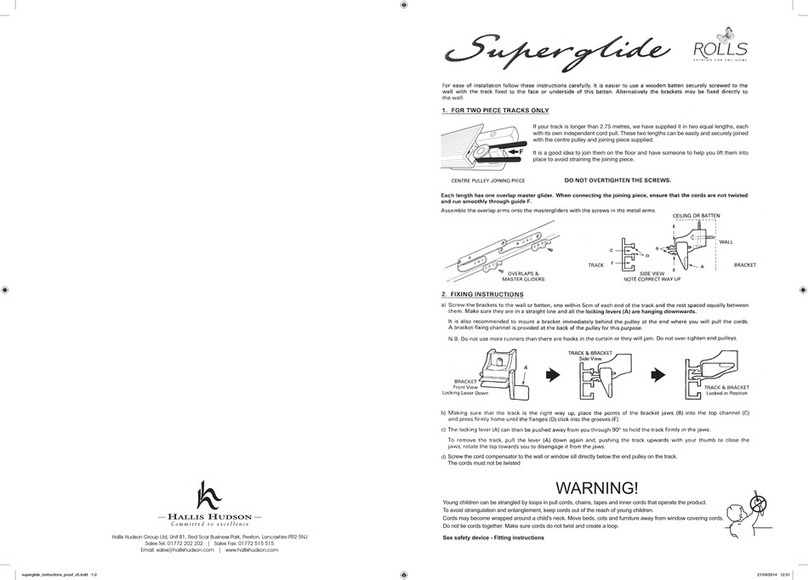

Mount the Installation Brackets — Outside Mount

To attach the end brackets, a flat vertical surface of at least 1

3

⁄

4

" is required for 2" and 2

1

⁄

2

" slat sizes.

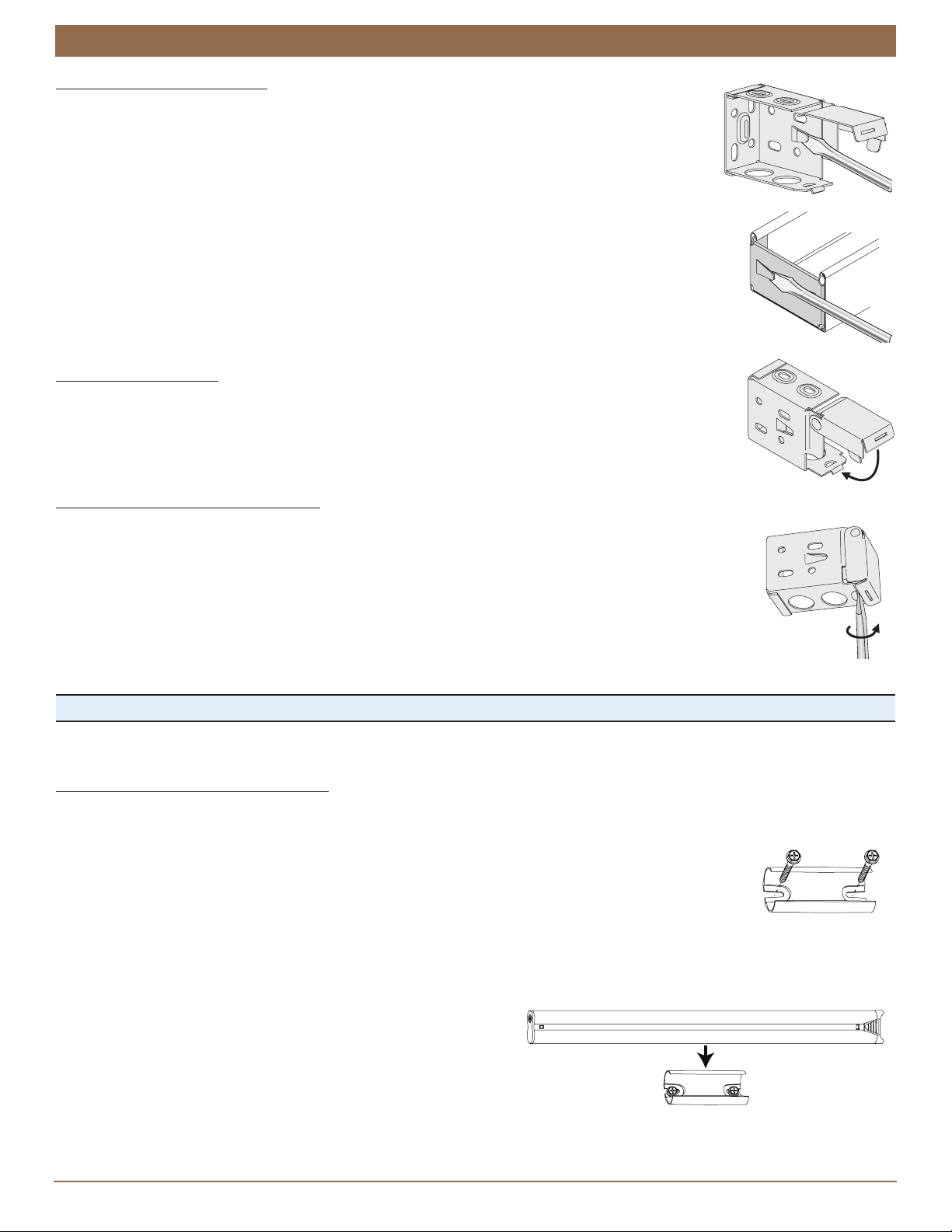

Mark the End Bracket Locations

Mark where the ends of the headrail will be located.

Center the headrail over the window opening at the desired height.

Use a pencil to lightly mark each end of the headrail.

Alternatively, measure the width of the headrail and use that

width to mark the headrail end points over the window opening.

Make a second mark

1

⁄

4

" to the outside of the headrail

end marks. The outer marks are where the outside

edges of the end brackets will be located.

Side/Top

Mount

Top Mount

Intermediate

Bracket

End

Bracket

End

Bracket

Space Evenly Space Evenly

Mark

Measure and Mark

1

∕

4

"Out from

Ends of Headrail

Mark