• Do not exceed maximum pressure

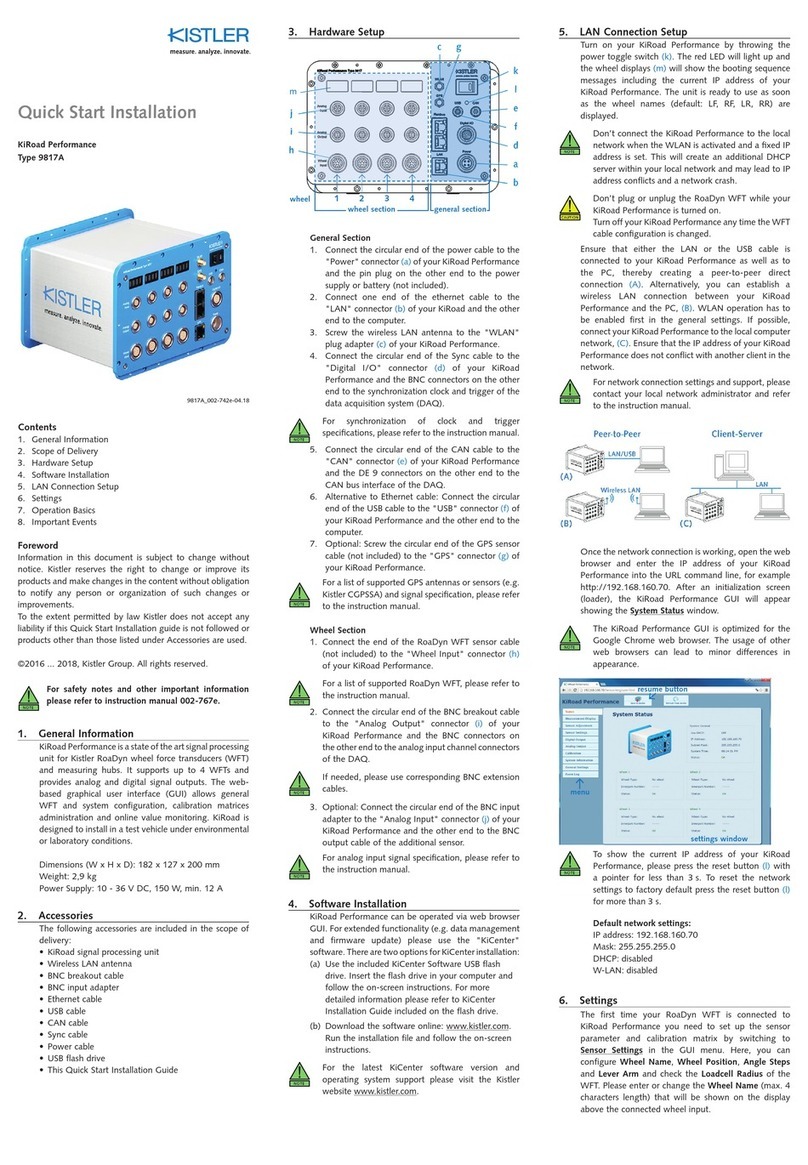

6.2 Coaxial cable

6.2.1 Installation of coaxial connector

Install connector and mounting plate in recess. Attach cap

using one of the screws. Place cap on open connector.

7. Installing Identification Plate

Rivet plate to mold or secure with four M2,5 screws.

Kistler Group

Eulachstrasse 22

8408 Winterthur, Switzerland

Tel. +41 52 224 11 11

Fax +41 52 224 14 14

info@kistler.com www.kistler.com

6.1.2 Installing Single-Wire Connector

Install connector and mounting plate in recess. Attach cap

using one of the screws. Place cap on open connector.

9211B_002-414e-10.15 Kis400 ©2008...2015, Kistler Group

5.3 Ejector Pin Clearance

The ejector pin is used to record the force transmitted during

molding. The ejector plate assembly must not preload the sen-

sor. Check that the sensor has a clearance of 0,03 ... 0,05 mm.

Test by lifting the ejector pin; it should turn smoothly.

• Do not preload sensor

• For multi-cavity installations only mark the side of

the pin head

Installation of Multi-Channel Connector

Example: Type 1708...

Installation of Connector Type 1839 and Mounting Plate

8. Functional Test

Check sensor insulation and functionality after mold assem-

bly is complete.

• Ensure that connector is dry

• Use cleaning spray Type 1003

8.1 Insulation Test

Use insulation tester Type 5495 to check sensor insulation.

Resistance >1013 Ω.

8.2 Sensor Functional Test

Effective pressure sensitivity by referring to actual front ejec-

tor pin diameter. Do trial run on molding machine to obtain

actual measurement data.

8.3 Securing Extension Cable

Cable must be restrained to prevent measurement errors.

Attach cable to ejector plate or moving platen.

9. Service and Repair

Piezoelectric sensors are maintenance-free. Insulation and

function of installed sensor should, however, be checked

before each molding run.

• Ensure that connector is dry

• Cover sensor hole during cleaning

• Use cleaning spray Type 1003

9.1 Insulation Test

Use insulation tester Type 5495 to check sensor insulation.

Resistance >1013 Ω.

9.2 Sensor Functional Check

Sensor is tested in its measuring position on the molding

machine. Use the effective sensitivity as described in Chapter

8.2 above.

9.3 Removing Sensor

Carefully disassemble ejector plate and use a magnet to lift

sensor from hole.

• Do not use penetrating spray before sensor is

removed

• Do not remove sensor by pulling on cable

• Use magnet to lift sensor out of hole

9.4 Cable Installation

Fix Sensor and unscrew cable with open-end wrench Type

5.210.164.

9.5 Single-wire repair

Slightly damaged cables can be repaired using the Repair

Kit Type 1207. Solder severed single-wire cables, slide over

Teflon tube and cover with shrink tube.

• Do not overheat sensor and cable with hot air blower

9.6 Repairs at Kistler

Factory repairs at Kistler are arranged by the local sales office

Info www.kistler.com

9.7 Disposal Instructions for Electrical and

Electronic Equipment

Do not discard old electronic instruments

in municipal trash. For disposal at end of

life, please return this product to an autho-

rized local electronic waste disposal service

or contact the nearest Kistler Instrument

sales office for return instructions.

• Ensure strain relief of extension cable

Diameter

[mm]

Sensitivity

[pC/bar]

Max. Pressure

[bar]

1,6 −0,88

>3 000

2 −1,38

2,5 −2,16

3 −3,11

4 −5,53 2 000

5 −8,64 1 250

SP= A x SFx 0,1 SPPressure sensitivity [pC/bar]

A Area of ejector pin d1

A = (d1/2)2 x π [mm2]

SFForce sensitivity [pC/N], as per

identification plate

• Always use thrust washer Type 9411

5.2 Sensor Installation in Spacer Plate

Install sensor in machined opening in spacer plate. Spacer

plate must lie flat on the base plate. Sensor face should stand

proud. Installed sensor must be at right angles and lie flat.

5.4 Machining Ejector Pins

To avoid side forces and force shunts on the pin, a maxi-

mum angle of 7° at the front is permitted.

6. Installing Cable and Connector

• Check again that edges of cable channel and hole

are chamfered

• Use a metal plate to cover open channels/slots

• Attach cap and place on connector

6.1 Single-Wire Technology

• Ensure electrical shielding; Enclose Single-wire cable

completely in mold

• Single-wire cable may not be run with power cables

• Ensure that all contact surfaces and threads are clean

and dry

6.1.1 Cut & Grip Connection

Cut the single-wire cable to length and do not strip the

insulation. Loosen the knurled connector by hand without

removing the rear section.

5.1 Sensor Installation in Ejector Plate

Insert thrust washer Type 9411 into blind hole and install sen-

sor on top. Sensor face should stand proud. Installed sensor

must be at right angles and lie flat.

Winterthur Switzerland

Kistler Instrumente AG

Made in Switzerland

Force Sensor

Type

SN

Sensitivity pC/N

Measuring range bar

Measuring pin Ø mm

interne und externe Fertigung

55147987

b

100009961 12.10.2015

12.10.2015 Hs

Hoh 100.239.050

9223A__

551456213.0255

12.10.2015

Bl.

Typenschild 75x25x0,5 mit Beschriftung

A4 1 / 1

1:1

measure. analyze. innovate.

Erstmals verwendet

Erste Proj.-Nr.

Werkstoff

Änderung Datum Massstab

Ersatz für Kopie Datum

gez.

gepr.

ges.

Hs

12.10.2015

Beo12.10.2015

Zeichnungs-Nr.

Material-Nr.

KIWAG-SWX_A4h

Ver.

Das Urheberrecht an dieser Zeichnung, die dem Empfänger

persönlich anvertraut wird, verbleibt unserer Firma.

Ohne unsere schriftliche Genehmigung darf die Zeichnung

weder kopiert noch vervielfältigt, noch an Drittpersonen

mitgeteilt oder zugänglich gemacht werden.