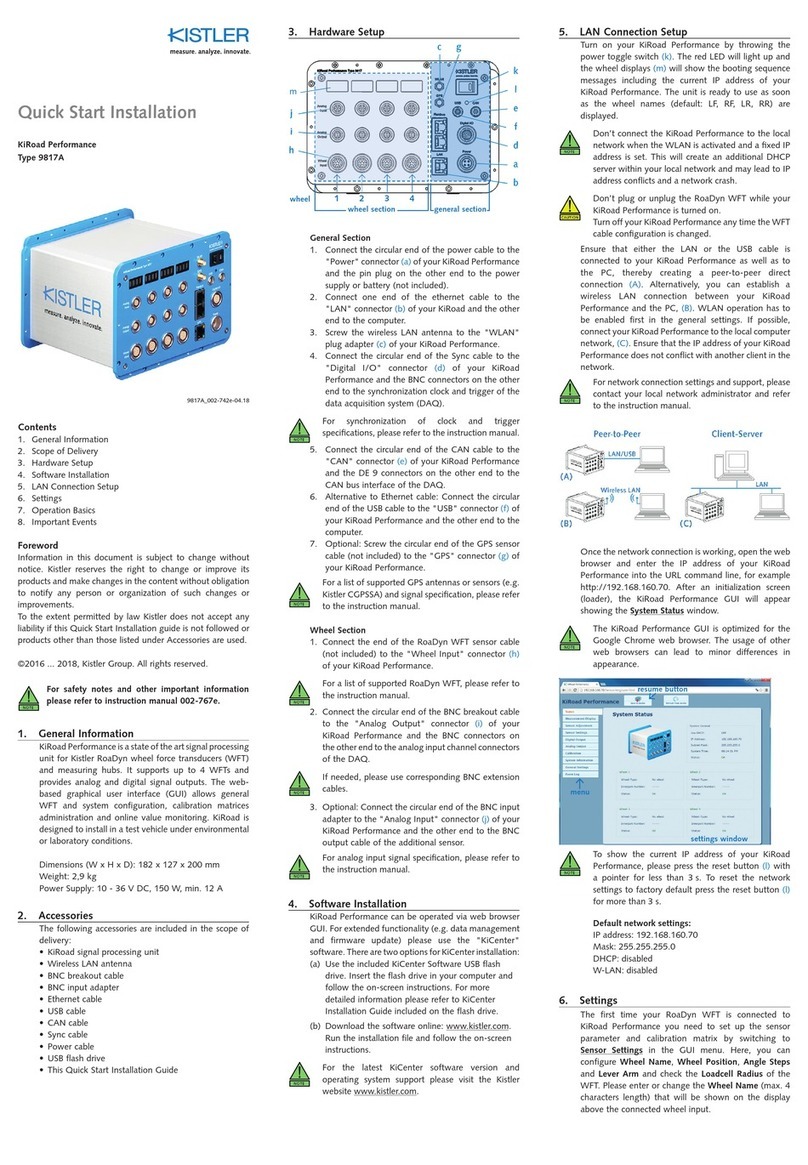

Quick Start Installation

Melt pressure measuring chain with ø7,8 mm sensor and

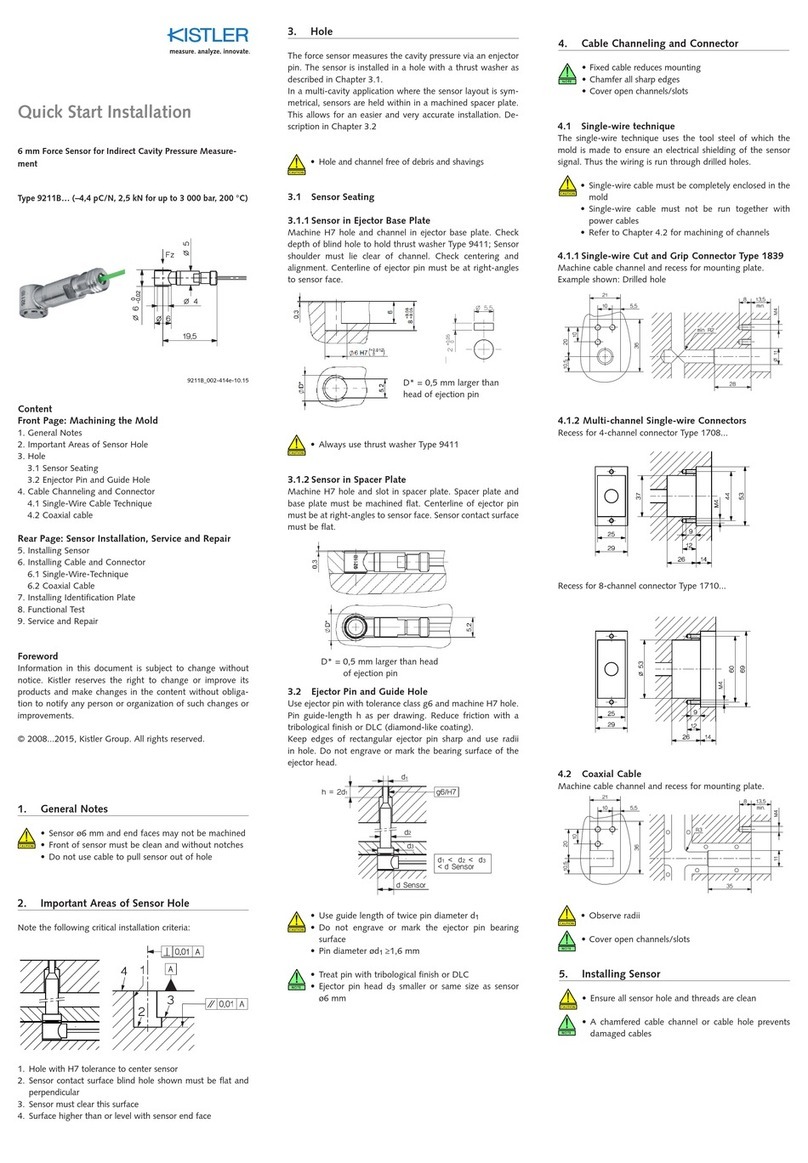

½"20 UNF thread

Type 4021B…

1. General

• Diameter of sensor must not be machined

• Front and rim of sensor must be clean and free from

scoring

• Do not touch diaphragm on front of sensor with

sharp tool

• Only use recommended mounting tool

• Each sensor belongs to its unique charge amplifier.

Otherwise a measurement cannot be assured. Please

check: The sensor must have the same serial number

as the amplifier.

4021B_002-597e-08.20

Contents

Front page: forming sensor bore

1. General

2. Important aspects of bore

3. Forming bore

4. Checking bore

4.1 Checking bore, thread and seal seat

4.2 Finishing bore

5. Mounting sensor

6. Taring measurement/operating test

6.1 Taring by means of machine control system

6.2 Taring with PIN 3 and PIN 8

Back page: servicing, taring measurement/operating test,

Kistler factory calibration, servicing and repair

7. Servicing

8. Taring measurement/operating test

9. Kistler factory calibration

10. Servicing and repair

Foreword

Information in this document is subject to change without

notice. Kistler reserves the right to change or improve its

products and make changes in the content without obligati-

on to notify any person or organization of such changes or

improvements.

To the extent permitted by law Kistler does not accept any

liability if this Quick Start Installation guide is not followed or

products other than those listed under Accessories are used.

© 2012 ... 2020 Kistler Group. All rights reserved. Kistler

Group products are protected by various intellectual property

rights. For more details visit www.kistler.com.

• Use fork wrench 13 for HA & HS versions

• Use fork wrench 19 for H0, H1 and H2 versions

Heat empty (unpressurized) nozzle up to operating tempera-

ture (>150 °C) and retighten to torque of 40 N∙m.

• If the sensor leaks, tighten to maximum of 45 N∙m

6. Taring measurement/operating test

At operating temperature (>150°C) and with nozzle empty

(unpressurized), connect sensor to measuring chain and tare:

6.1 Taring by means of machine control system

Apply voltage to tare conductor.

6.2 Taring with PIN 3 and PIN 8

Short the two pins. Pin 8 must be live for this purpose!

5. Mounting sensor

• Sensor bore and thread must be clean

• Seal must be positioned on the sensor

Apply copper paste, Molykote or high-temperature grease

sparingly to thread and sealing surface.

Screw sensor in at room temperature.

Tightening torque 40 N∙m.

• If measurement noise arises when there is a large elec-

trical potential difference between nozzle and control

unit, the shield of the cable must not be connected to

the control box

7,8

0

-0,03

3

4

10,5

0

-0,03

2. Important aspects of bore

Attention must be paid to the following aspects:

1. Ensure sensor centered

2. Seal seat

3. No centering bore

4. Do not mount sensor so it protrudes

A

0,1 A

1

2

3

4

3. Forming bore

Form the bore with ½" thread and seal seat as shown on the

following drawing.

Then ream bore with Ø7,94 mm ream (Mat. No. 65007827).

• Keep perpendicular and centered

max. R0.1

A

0,1 A

3,05

+0,05

0

0,5

+0,1

0

max.3

max.24

7,94

+0,05

0

11,5

+0,1

0

10,05

+0,05

0

4. Checking bore

Use the following tools to check and rework the measuring

bore:

4.1 Checking bore, thread and seal seat

The limit plug gage (Mat. No. 65000124) and fork wrench

11 (Mat. No. 65007836) are used together with Kistler grease

Type 1063 to check the bore and its perpendicularity.

• Always use Kistler grease Type 1063

4.2 Finishing bore

The Ø7,94 mm reamer (Mat. No. 65007827) can be used to

finish the bore.

Connection to supply and output signals

M12x1 industrial connector, 8-pole male

# Signal Cable Type 1787A5

wire color

1 Exct. GND white

2 Signal GNG brown

3 Tare green

4 Pressure signal 0 ... 10 V (at P1)

or 4 ... 20 mA (at P2) yellow

5 Temp. signal 10 mV/K (at P1)

or 20 μA/K (at P2) grey

6 res. pink

7 res. blue

8 +Exct. (18 ... 30 V) red

Requirements for structure material of the measuring bore

(Nozzle body)

Min. Max.

Hardness HRC 40 55

Tensile strength Mpa 1 200 1 820