IM-T-287C Jun. 2021

DTS-A-100 DISPLACEMENT TRANSDUCER INSTRUCTION MANUAL

Thank you for purchasing the KYOWA product. Before using it, read this

instruction manual carefully. Also, keep the manual within easy reach so that

you can refer to whenever necessary.

Specifications and dimensions described in this manual could be changed

without notice. Please visit our website for the latest version.

1. Calling the operator’s attention

The following cautionary symbols and headlines are used to invite the

operator’s attention. Be sure to observe the accompanying precautions in

order to safeguard the operator and preserve the performance of the

instrument.

Warning Improper handling can cause serious injury to the

operator.

Caution Cautions are given to invite the operator’s attention, in

order to avoid instrument failure or mal-function.

2. Important notice

Unless specified, the transducer must not be used under hydrogen

environment.

3. Safety Precautions

Warning

●

As you push the rod inward, the rod returns to its initial position by

reaction force. Handle the product with care to avoid eye poking.

4. Handling Precautions

Caution

●

Do not apply excessive axial or bending force on the rod.

●

Do not rotate the rod. (For replacing accessories, see 9.)

●

Do not disassemble the product.

●

Do not use the product under water and dusty environment.

●

Use the product under environment without vibration.

●

Pay similar attentions toward the product as one gives to regular dial

gages.

●

Always keep the rod clean.

●

Make sure that the bending radius of cable is longer than 10 times of a

diameter of the cable.

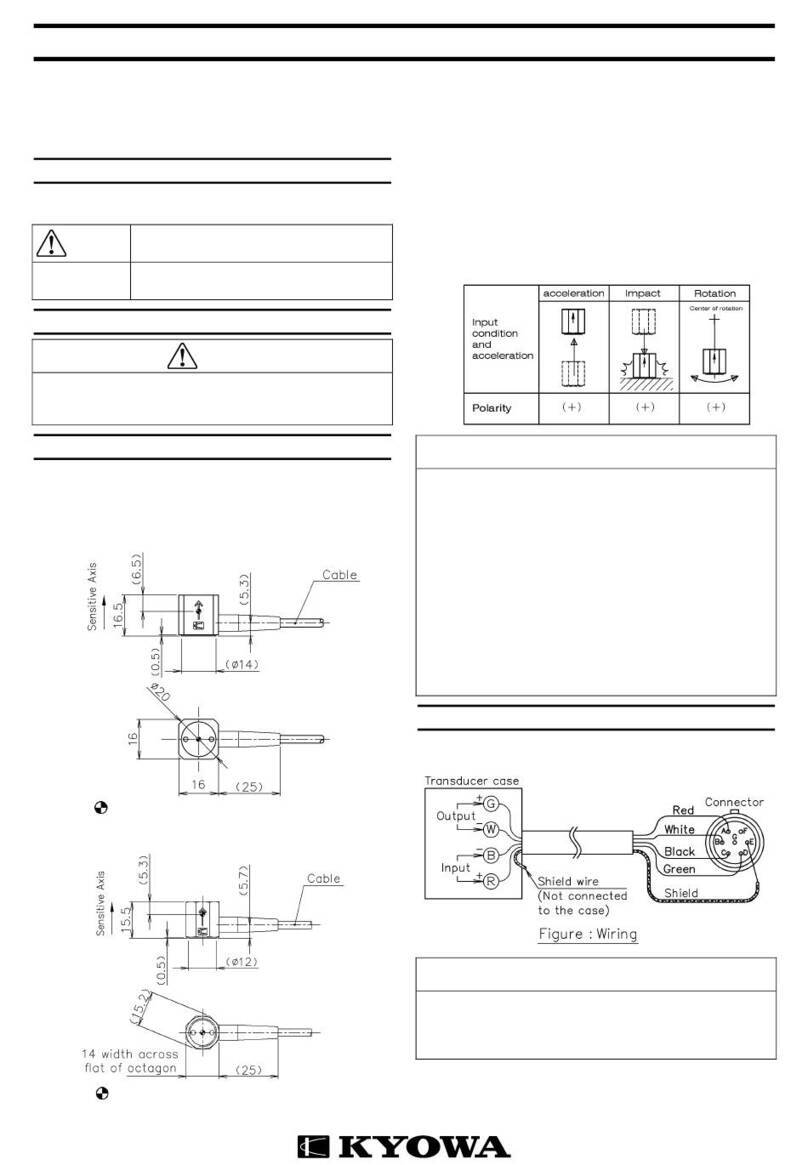

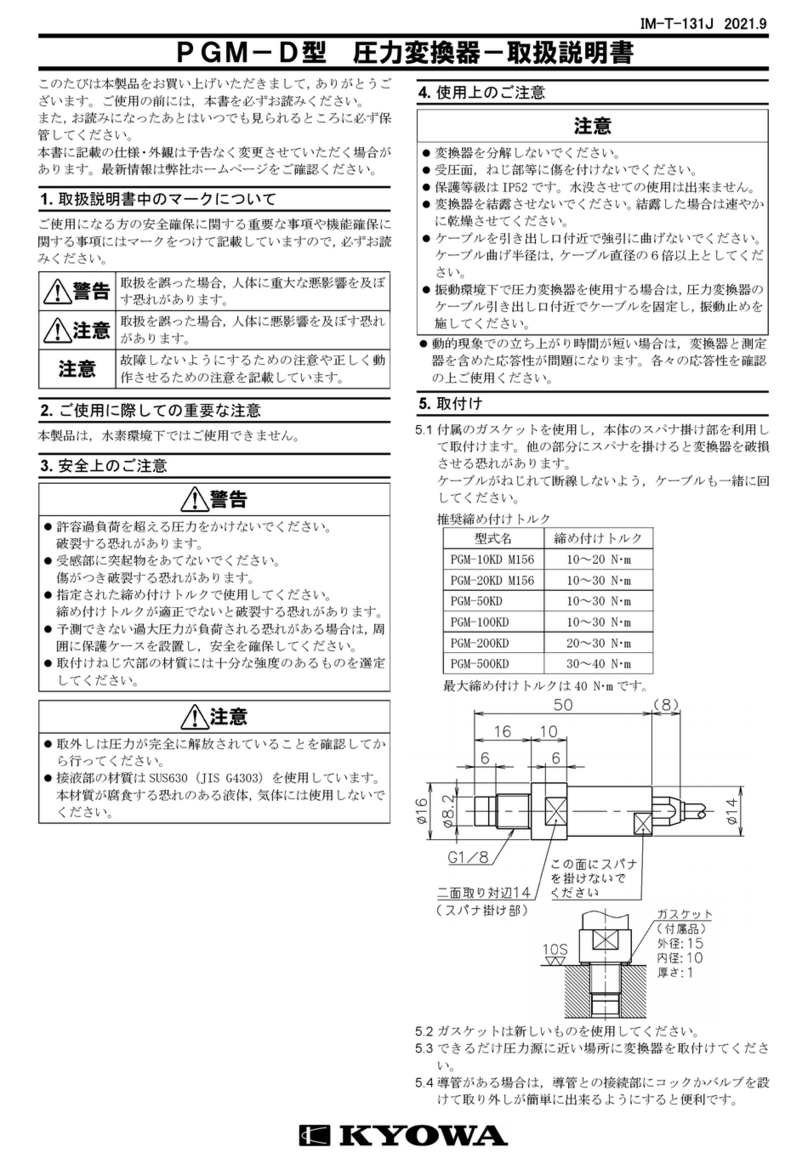

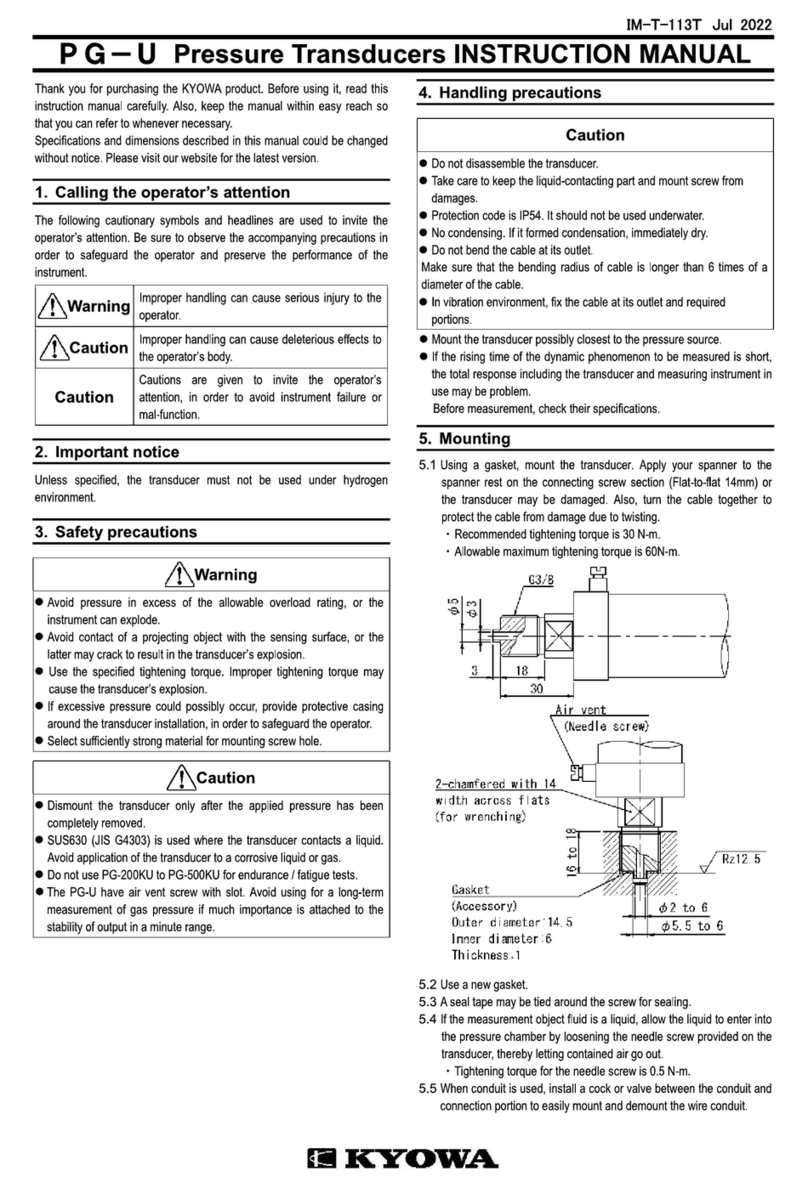

5. Installation

5.1 Fix the DTS-A to the fixed point by using the accessory 2 mounting

bands (FXBP-100A), 2 wing bolts (M4×12) and M6 bolt.

The M6 bolt is not included.

5.2 Make sure the displacement of 0.5 mm or more is applied to the DTS-A.

5.3 The DTS-A and dial gage measures data by contacting the probe onto

the measuring point. However, some DTS-A rods may not track dynamic

data correctly. Make sure the rods works correctly.

5.4 To fix the rod to the measuring point, remove the prove and fix the rod to

the measuring point by using a screw (M2.5).

5.5 To measure displacement by pulling the rod, connect the accessory

adapter into the rod end.

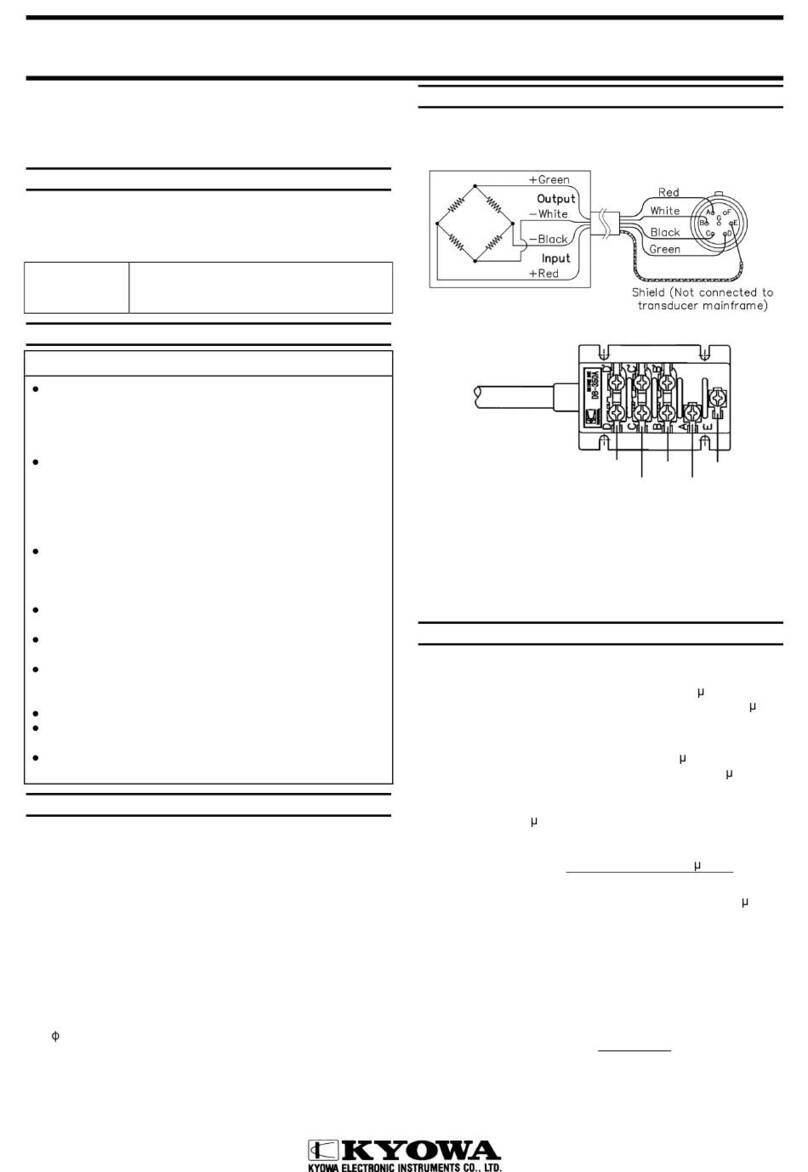

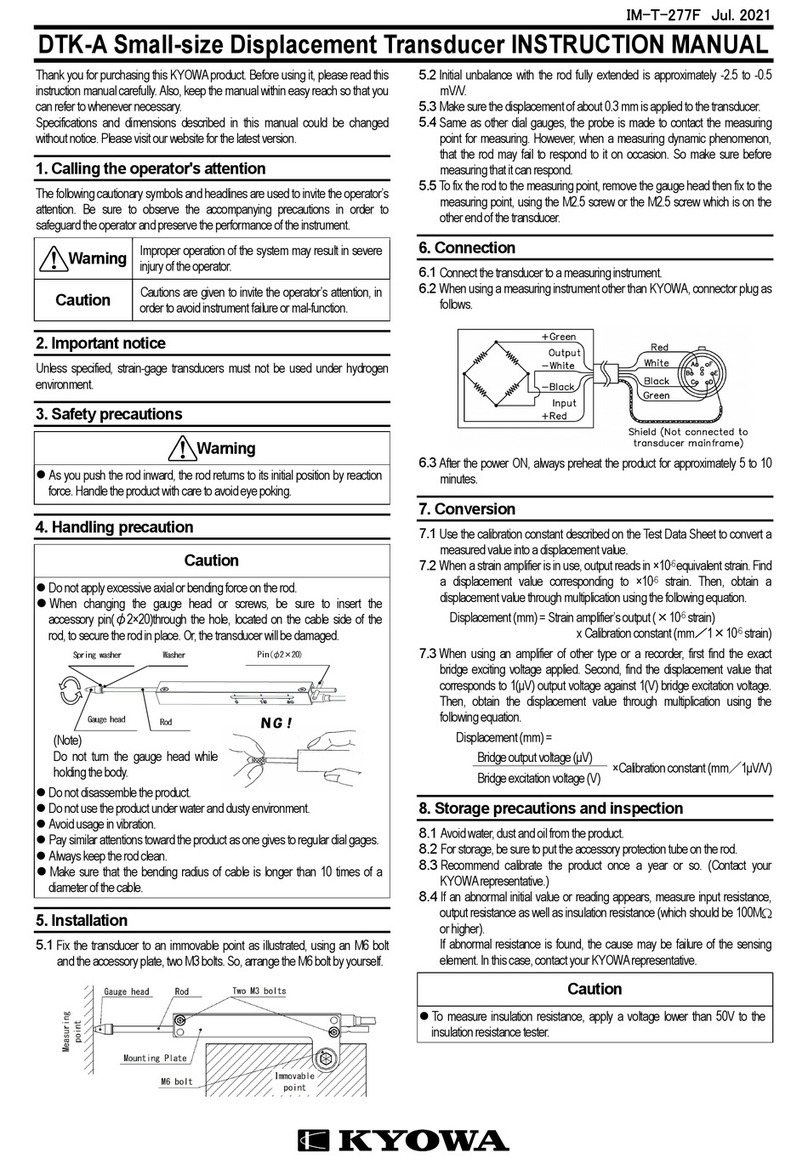

6. Connection

6.1 Connect the DTS-A to a measuring instrument.

6.2 Connect the connector plug as follows.

(Shield is not connected to the chassis.)

6.3 After the power ON, always preheat the product for approximately 5 to 10

minutes.

7. Conversion

7.1 Use the calibration constant described on the Test Data Sheet to convert

a measured value into a displacement value.

7.2 When a strain amplifier is in use, output reads in ×10-6 equivalent strain.

Find a displacement value corresponding to ×10-6 strain. Then, obtain a

displacement value through multiplication using the following equation.

Displacement (mm) =Strain amplifier’s output (×10-6 strain)

x Calibration constant (mm/1×10-6 strain)

7.3 When using an amplifier of other type or a recorder, first find the exact

bridge exciting voltage applied. Second, find the displacement value that

corresponds to 1(μV) output voltage against 1(V) bridge excitation voltage.

Then, obtain the displacement value through multiplication using the

following equation.

Displacement (mm) =

Bridge output voltage (μV) ×Calibration constant (mm/1μV/V)

Bridge excitation voltage (V)

Sensitivity Decrease due to Cable Extension

If a strain-gage transducer is connected to a signal conditioner, digital

indicator or strain amplifier via extension cable, we will not ignore the

sensitivity decrease due to the extension cable resistance which lowers

the voltage applied to the transducer.

The rated output with lowered sensitivity is obtained from the following

equation:

Rated output :ε0=( R)εi

R+(r × L)

R:Transducer’s input resistance (Ω)

r

:Extension cable’s reciprocating resistance (Ω/m)

L:Extension cable length (m)

εi:Rated output written in the Test data sheet

DTS-A

Connector plug

Adapter