GMTRK4

Installation and Operation Manual

Go to Table of Contents PG 3/42 REV: BETA (4/4/2020)

Table of Contents

1. LIST OF FIGURES................................................................................................................................... 5

2. How to Use this Manual ...................................................................................................................... 6

2.1. Interactive Manual using Adobe Reader...................................................................................... 6

2.2. Your Kit SKU Number and this Manual ........................................................................................ 6

2.3. Illustration/Photo Details and Orientation .................................................................................. 6

3. Safety First ........................................................................................................................................... 7

4. Application Chart................................................................................................................................. 8

4.1. Bolt-On Vehicle List ...................................................................................................................... 8

4.2. **Excluded Vehicles..................................................................................................................... 8

4.3. Aftermarket Product Compatibility.............................................................................................. 8

5. Installation Overview........................................................................................................................... 9

5.1. Kit Layout and System Location(s) ............................................................................................... 9

5.2. Install Process Outline................................................................................................................ 11

5.3. Approximate Installation Time................................................................................................... 11

6. List of Tools and Supplies .................................................................................................................. 12

6.1. Standard Tool List (Required)..................................................................................................... 12

6.2. Special Tool List (Recommended).............................................................................................. 12

6.3. Shop Consumables List (Recommended)................................................................................... 12

7. Parts List............................................................................................................................................. 13

7.1. Before Starting, Review Parts List.............................................................................................. 13

7.2. Pre-Packaged Electro-Mechanical Kit Items .............................................................................. 13

7.3. Air Fittings and Related Items .................................................................................................... 14

7.4. Electrical Small Components and Related Items ....................................................................... 15

7.5. Bolt-On Mounting Brackets & Special Hardware....................................................................... 16

7.6. Hardware, Fasteners and Soft Parts........................................................................................... 17

7.7. Add-On Accessories.................................................................................................................... 19

8. Bench Assembly................................................................................................................................. 20

8.1. Assemble Air Fittings to Air Tank ............................................................................................... 20

8.2. Assemble Air Filter to Air Compressor....................................................................................... 21

8.3. Disassemble Trumpets from Air Horn Drivers ........................................................................... 21

8.4. Assemble Air Horn Driver to Horn Bracket (GMTRK-4-301) ...................................................... 22

8.5. Insert Square Neck Bolts onto Brackets (GMTRK-4-102, 201)................................................... 24

9. On-Vehicle Mechanical Assembly ..................................................................................................... 25

9.1. Trim Driver’s Side OE Leaf Spring Shackle Bolt .......................................................................... 25

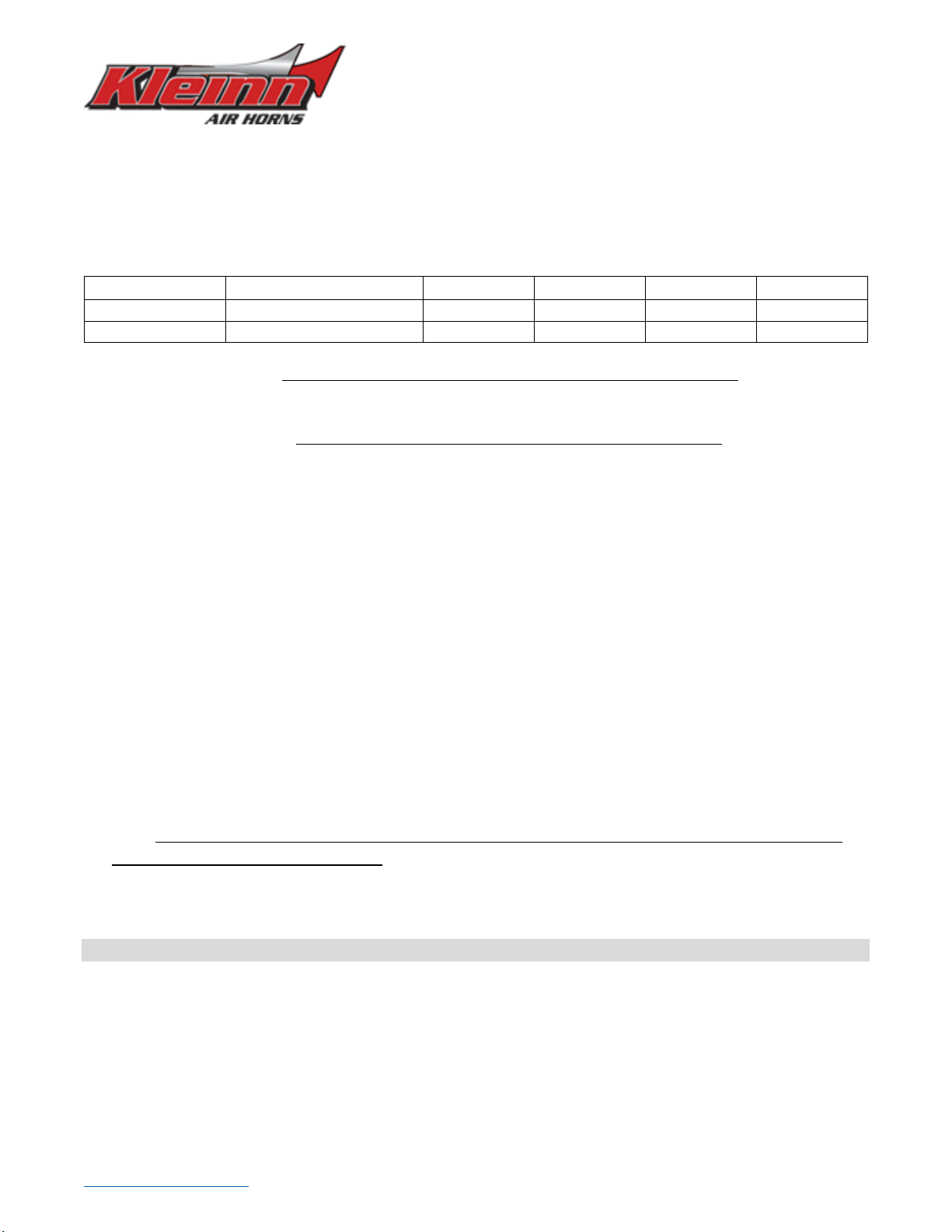

9.2. Install Air Tank & Compressor Bracket (GMTRK-4-201) & Bolt Plate (-102).............................. 26

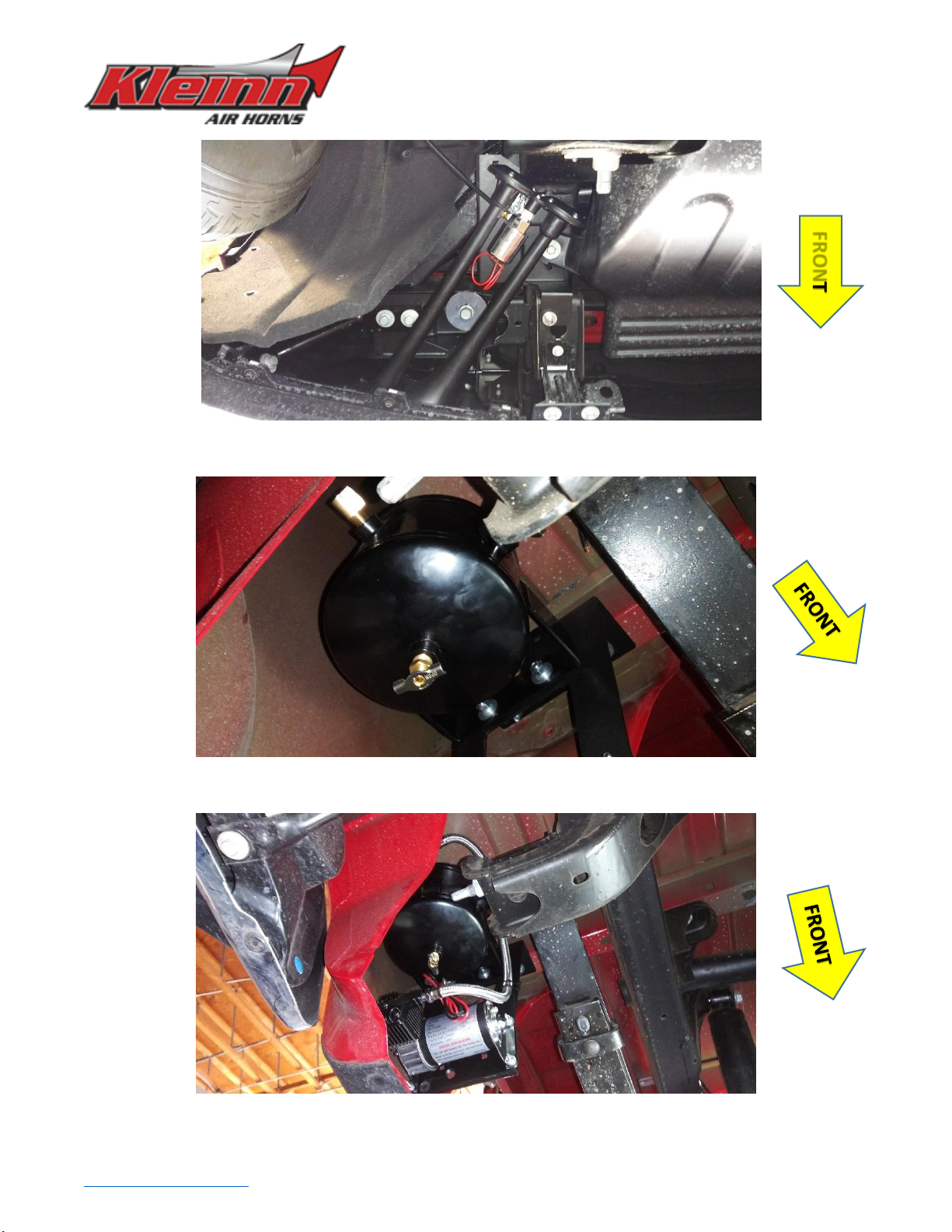

9.3. Install Air Tank............................................................................................................................ 28

9.4. Install Air Compressor................................................................................................................ 30

9.5. Connect Air Compressor Leader Hose to Air Tank..................................................................... 31

9.6. Remove OE Engine Shield & OE Clip-On Nut ............................................................................. 32

9.7. Install Air Horn Driver Sub-Assembly & Connect Air Tubing...................................................... 33

9.8. Connect Air Horn Tubing to Air Tank ......................................................................................... 35

9.9. Final Trumpet Installation .......................................................................................................... 36