Thank you for choosing our product. We are glad that you have made a really good choice.

Every your comment concerning the device operation will be welcomed.

The HoGas duo boiler operation control is a modern microprocessor system, chich controls not only the

boiler, but also central heating and warm utility water.

A sophisticated operation algorithm and possibility of regulation of many parameters allow a very

flexible adjustment to a concrete system.

An alphanumeric display significantly facilitates communication between the device and user and

significantly simplifies operation.

PRECAUTIONS

Warning: danger of electrical shock.

•Disconnect power supply in the electrical switchboard before mounting or dismounting.

•Please read the attached instruction manual carefully before beginning to use the device.

•Please keep this instruction manual for further reference.

•Please follow all rules and precautions provided in his instruction manual.

•Make sure that the device is not damaged. If you have some doubts, stop using the device and contact your supplier.

•Please contact your supplier if you have any doubts concerning the safe exploitation of his device.

•Pay special attention to all warning labels on the device casing and packaging.

•This device should be used according to its purpose.

•This device is not a toy; don’t allow children to play with it.

•Never allow children to play with any part of any part of packaging of his device.

•Small parts, such as fastening screws, should be kept away of young children. The supplied unit may contain such elements

which may be swallowed and impose a choking hazard.

•No mechanical or electrical changes should be made on the device. Such changes may cause inappropriate operation of the

device which could be incompatible with the standards and impose a negative impact on the operation.

•No objects should be put inside the device through the apertures (for instance, through the ventilation apertures), as this

may cause a short circuit, electrical shock, fire or damage to the device.

•Do not allow water, moisture and dust to get inside the device, as it may cause a short circuit, electrical shock, fire or

damage to the device.

•A proper ventilation of the device should be ensured; ventilation apertures should not be blocked; free air circulation

around the device should be ensured.

•The device id foreseen for assembly inside premises, unless it is adapted to work outside.

•The device should not be exposed to any shock or vibration.

•Before connecting the device, make sure, that the parameters of the energy supply matches the device specifications.

•To avoid electrical shock, the device should be connected to the electrical socket with a protective earthing pin. The

earthing of the socket should be properly made by an authorized electrician.

•Before connecting the device, make sure, that this will not cause overload of the electrical circuit. Avoid connecting the

device to the same circuit as engines and other appliances that generate pulse interferences (for instance. Washing

machines, refrigerators, etc.)

•It is absolutely necessary to disconnect the device from the power supply before connection of any cables and peripheral

appliances to the device.

•To fully disconnect the unit from the mains, unplug the power cord from the power outlet, especially when it is not intended

to use for a longer time.

•The power supply cable should be protected from damages, and laid in a way so as to avoid trampling; no objects should

be put on the cable.

•All connections made should be compatible with the electrical mounting scheme installation as well as with national or local

rules on electrical connections.

•This device contains no parts which could be replaced by the user. All service operations except from cleaning and fuse

replacement (when the device is disconnected from the power supply) and function adjustments should be carries out by

authorized service shop.

•It is absolutely necessary to disconnect the device from the power supply before starting any maintenance operations.

•No benzine, solvents or other chemical agents should be used to clean the device housing in order to avoid damaging the

housing. It is recommended to use a soft cloth.

•The device should not be used absolutely if the power supply cable is damaged. A damaged cable should be replaced by the

repair shop with the one of the same parameters as original cable.

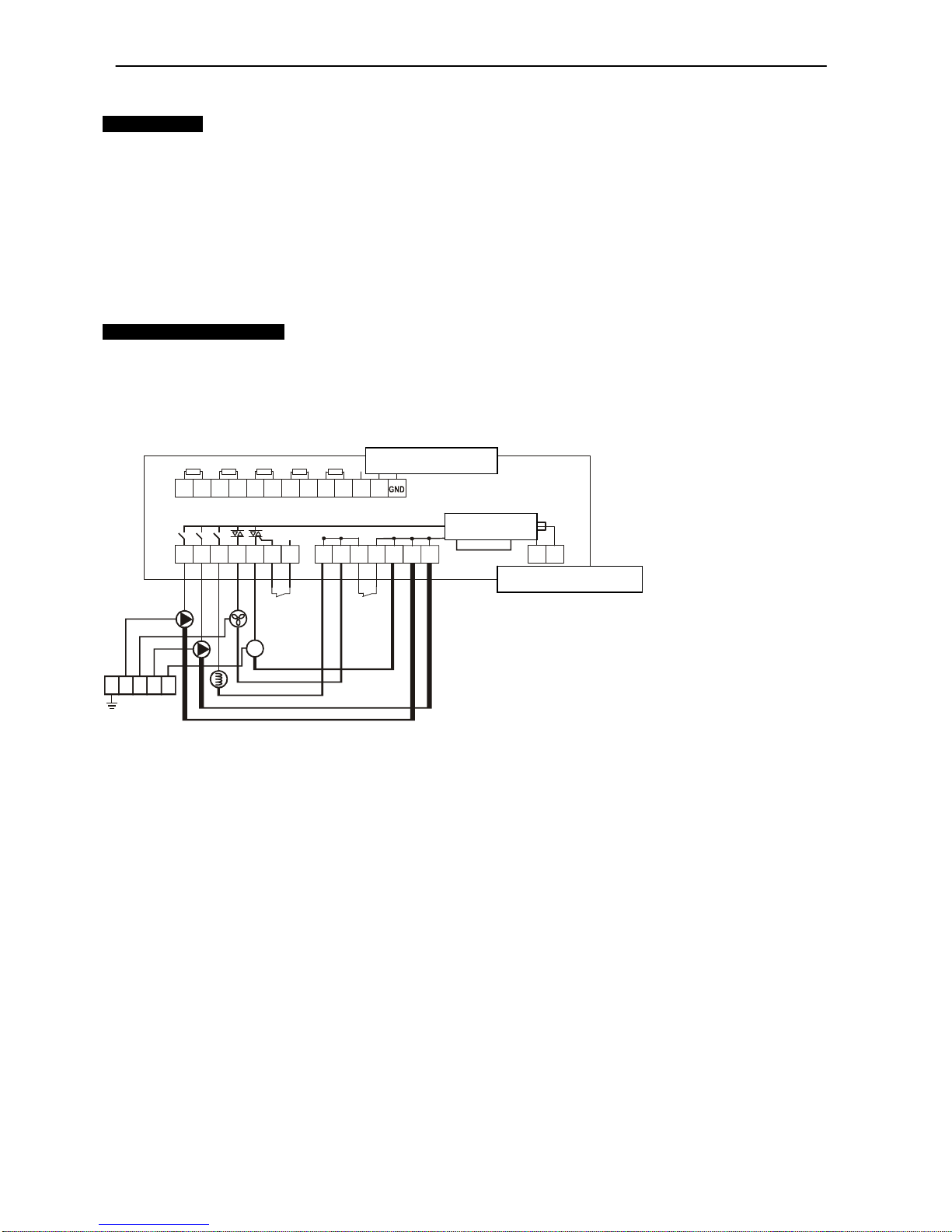

INSTALLATION

General requirements:

•Please read the attached instruction manual carefully before beginning to use the device.

•The person that undertakes to make assembly should have an appropriate technical experience.

•The connections made using a copper cable should be suitable for operation in the temperature up to +75ºC .

•All connections made should be compatible with the electrical mounting scheme installation as well as with national or local

rules on electrical connections.

Location:

These devices are foreseen for inside assembly only. Please make sure that the chosen location meets the following

conditions:

•The place of assembly should be free from excessive humidity and flammable or corrosive vapor.

•The device should not be assembled near powerful electrical apparatus, electrical machines or welding equipment.