TABLE OF CONTENTS

Introduction………………………………………………………………………………………………6

Important safety instructions……………………………………………………………….....................6

Some precautions………………………………………………………………………………............... 6

Conventions used in the manual………………………………………………………………………… 6

Destination of use…………………………………………………………………………………………. 7

Installation regulations……………………………………………………………………………………. 7

Health and safety………………………………………………………………………………………….. 7

The machine and the pellets…………………………………………………………………………. 8

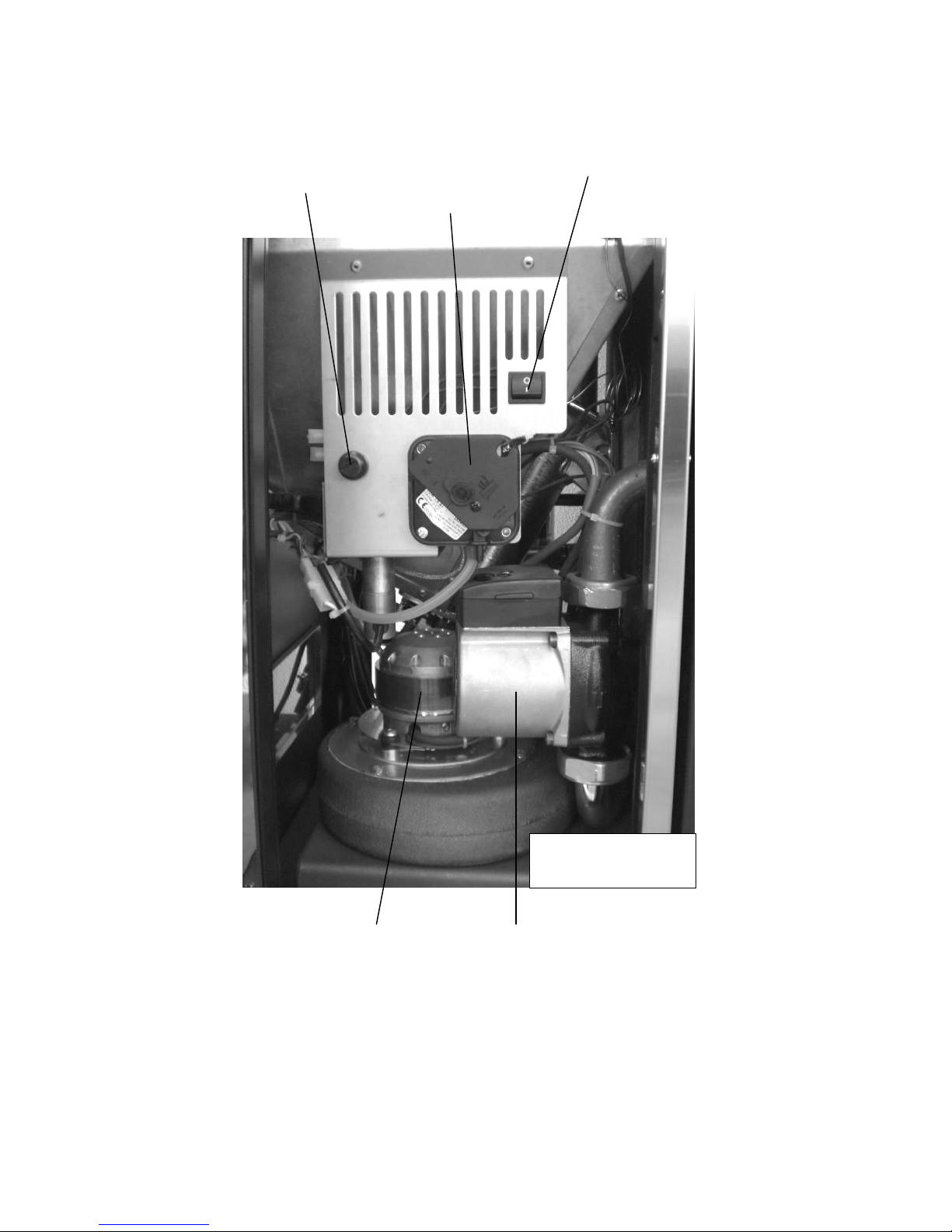

Central heating cooker components…………………………………………………………………….. 8

Connections data sheet (Model with upper flue gas outlet)…………………………………………...12

Connections data sheet (Model with rear flue gas outlet)…………………………………………….. 13

Technical features……………….…………………………………………………………………………14

Pellet features……………………………………………………………………………………………… 15

Requisites of the place of installation………..……………………………………………………..16

Positioning…………………………………………………………………………………………………..16

Spaces around and above the central heating cooker.……………………………………………….. 16

External air vent…………………………………………………………………………………………… 17

Flue and connection to the same –Chimney…………………………………………………………...17

Electric connection……………………………………………………………………………………. 21

Control of any coupled boiler…………………………………………………………………………….. 21

Control of a three-way motorised valve for the DHW system….................................................... 21

Connection to room thermostat….………………………………………………………………………. 22

Pipe connection………………………………………………………………………………………... 23

Connection examples…………………………………………………………………………………….. 24

Cleaning and Maintenance…………………………………………………………………………… 25

Precautions before cleaning……………………………………………………………………………… 25

Routine cleaning……………………………………………………………………………………………25

Extraordinary cleaning……………………………………………………………………………………. 27

Yearly cleaning…………………………………………………………………………………………….. 34

Cleaning the ceramic glass………………………………………………………………………………. 39

Cleaning the flue…………………………………………………………………………………………... 39

Maintenance………………………………………………………………………………………………. 39

The display……………………………………………………………………………………………….40

The menu…………………………………………………………………………………………………43

Commissioning………………………………………………………………………………………… 47

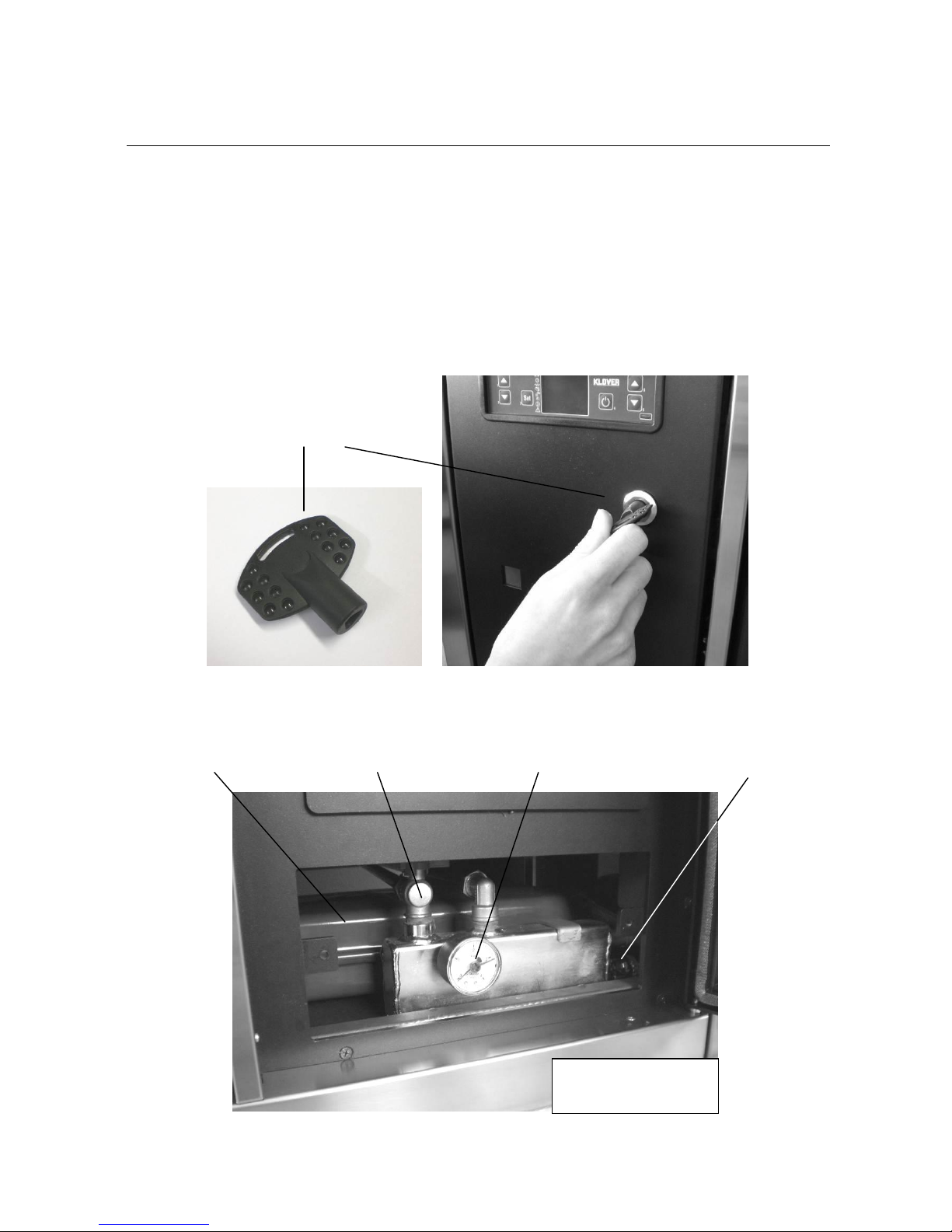

Filling the system for the first time………………………………………………………………………..47

Pellet loading and connection to the mains…………………………………………………………….. 47

Central heating cooker ignition cycle……….…………………………………………………………… 47

Central heating cooker working mode…………………………………………………………………...48

Producing domestic hot water (prepared models only)……………………………………………….. 49

Cooking plate/oven output………………………………………………………………………………...49

Central heating cooker switch-off………………………………………………………………………... 50

Modification of DHW, room and water temperature setting…………………………………………... 51

Alarms signal………………………………………………………………………………………………. 52

It must be known…………………………………………………………………………………………... 52

What happens if….…………………………………………………………………………………….. 53

Circuit board parameters……………………………………………………………………………... 54

Wiring diagram……..……………………………………………………………………………………56

Notes………………………………………………………………………………………………………57

Warranty…………………………………………………………………………………………………. 58