TM

KM 4-40C1M1 Infrared Asphalt Recycler Manual –v.5.25.21 Page 2

Phone: 810-688-1234 Toll Free: 800-492-1757 Fax: 810-688-8765

www.kminternational.com

© 2010 Keizer-Morris International. All Rights Reserved.

INTRODUCTION

The KM International Team would like to take this opportunity to THANK YOU for

your purchase of the KM 4-40 Infrared Asphalt Recycler (KM 4-40 IR). We at KMI are

confident that your newest Infrared asphalt surface heater will offer years of safe,

reliable and cost effective “IN PLACE ASPHALT RECYCLE and REPAIR.” KM

International, Inc. has acquired and developed a number of strengths that has

fostered KMI’s worldwide reputation as the “INFRARED PROCESS EXPERTS”. We have

designed, developed and set the “Gold” and “Green” standards for Infrared use. We are

the preeminent authority on the “Infrared Process” of in place “asphalt surface

heating” and “recycle and repair.” We have fostered an ongoing industry standard of

quality and excellence that continually exceeds our customers’ expectations in all of

our product offerings including our “Infrared” line of equipment, crack maintenance

and repair equipment, Hot Box Asphalt Reclaimers and Asphalt Recyclers.

Our commitment to the design and manufacture of the highest quality asphalt surface

maintenance and repair equipment on the market is not just a “quote on the wall” but

rather the driving force for the entire KMI team. Our 26 years in the Infrared and

asphalt maintenance industries has provided KM INTERNATIONAL the necessary

experience and knowledge of “IN PLACE ASPHALT RECYCLE and REPAIR” to give our

customers the “peace of mind” that only experience and knowledge can provide;

experience and knowledge that our customers have come to rely on. The Management

Team at KM INTERNATIONAL is confident that YOUR purchase of the KM 4-40 IR will

be the basis for a long standing and mutually profitable relationship. The Goal at KM

INTERNATIONAL has and will always be to manufacture infrared heaters that provide

our customers cost savings, purchase justification and profitability.

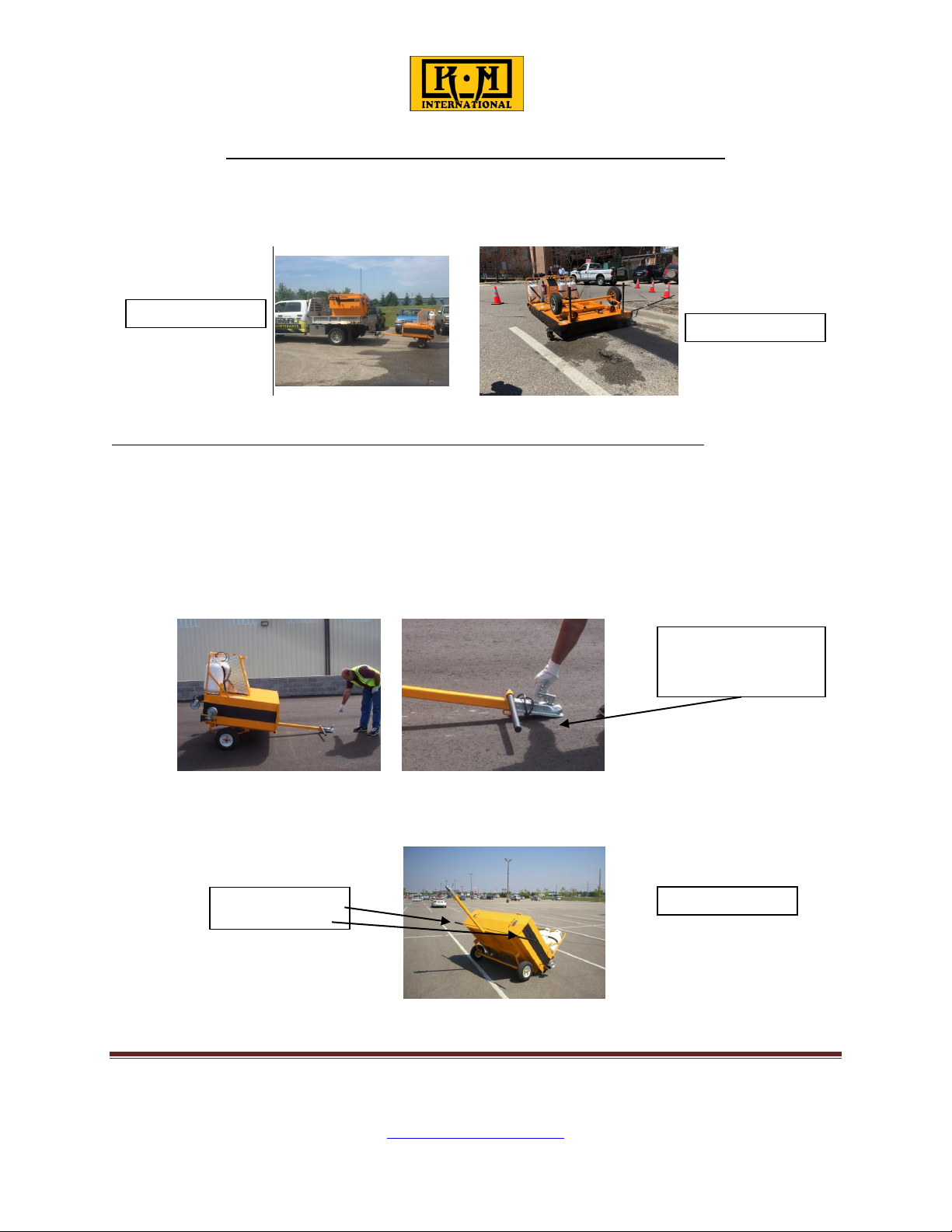

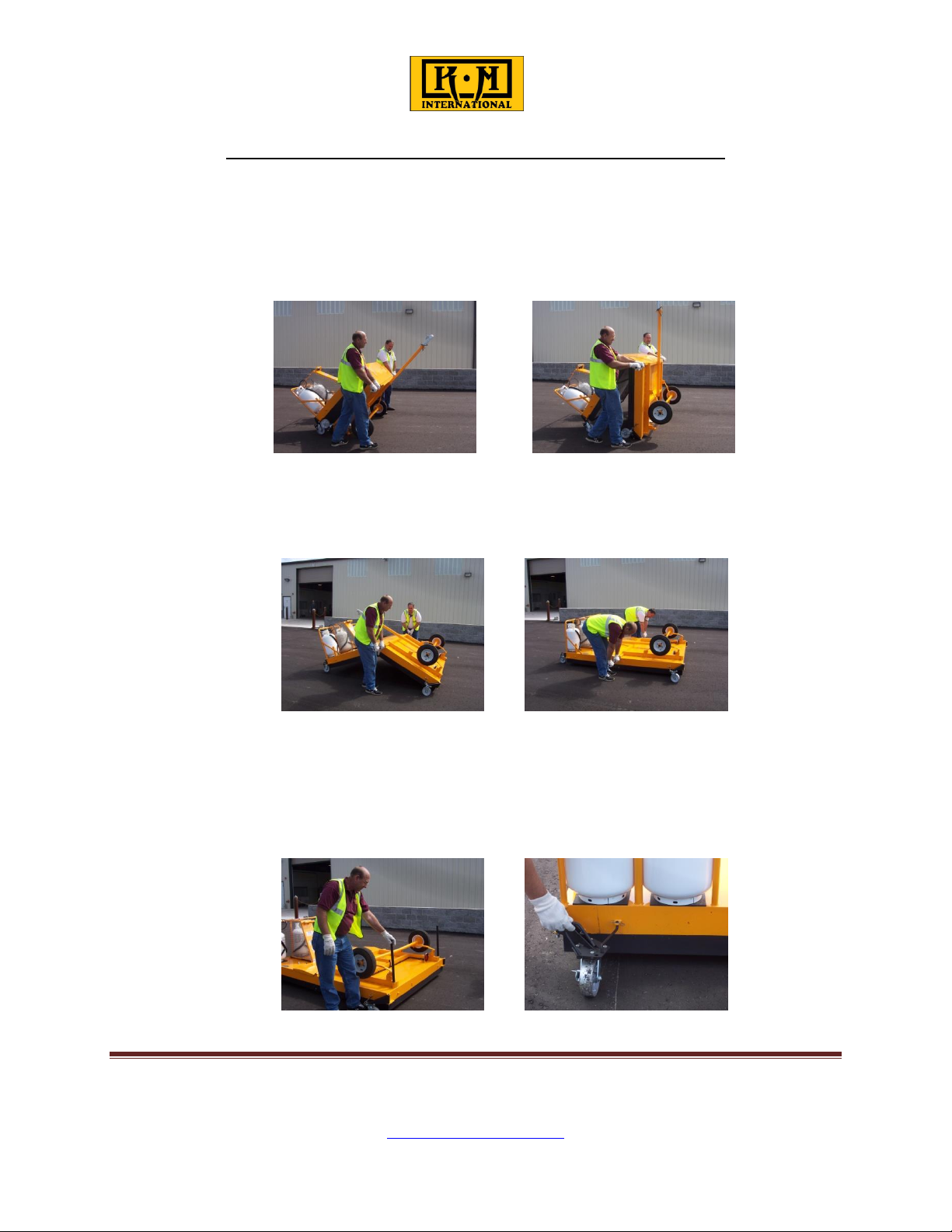

The KM 4-40 Infrared Asphalt Recyclers are designed to give years of dependable

high performance service. Their solid welded construction stands up well to

commercial use. The simple, straight forward design has little to go wrong and can be

maintained easily. Its patented fold up design makes the 4-40 IR easy to use,

transport and store.

The KM 4-40 Infrared Asphalt Recycler provides two (2) 2 foot x 4 foot (.6m x 1.2m)

and two (2) 3 foot x 4 foot (.9m x 1.2m) independently controlled infrared zones for a

total coverage of 8 foot x 5 (2.4 m x 1.5 m) foot (3.6 sq. meters), as the name indicates

four (4) zones for 40 sq. feet (3.6 sq m) hence the name KM 4-40 IR. It is designed to

be used to heat and repair asphalt of varying sizes and shapes making it the most

versatile and efficient Infrared Asphalt Recycler on the market.

The serial number for this machine is located on a serial tag on the front of the

machine. Please be sure to retain this manual. It is a convenient information source

that should be consulted regularly.