TM

KM T-2 C1M2 –v.Apr.15.4 Page 5

Phone: 810-688-1234 Toll Free: 800-492-1757 Fax: 810-688-8765

www.KMINTERNATIONAL.com

© 2010 Keizer-Morris International. All Rights Reserved.

Reporting Safety Defects

If you believe that your vehicle has a defect that could cause a crash or could cause

injury or death, you should immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying KM International Inc.

If the NHTSA receives similar complaints, it may open an investigation, and if it finds that

a safety defect exists in a group of vehicles, it may order a recall and remedy campaign.

However, the NHTSA cannot become involved in individual problems between you, your

dealer, or KM International, Inc.

To contact the NHTSA, you may either call the Vehicle Safety Hotline toll-free at 1-888-

327-4236 (TTY:1-800-424-9153), go to http://www.safercar.gov; or write to: NHTSA,

1200 New Jersey Ave SE, Washington, DC 20590. You can also obtain other

information about motor vehicle safety from http:www.safercar.gov.

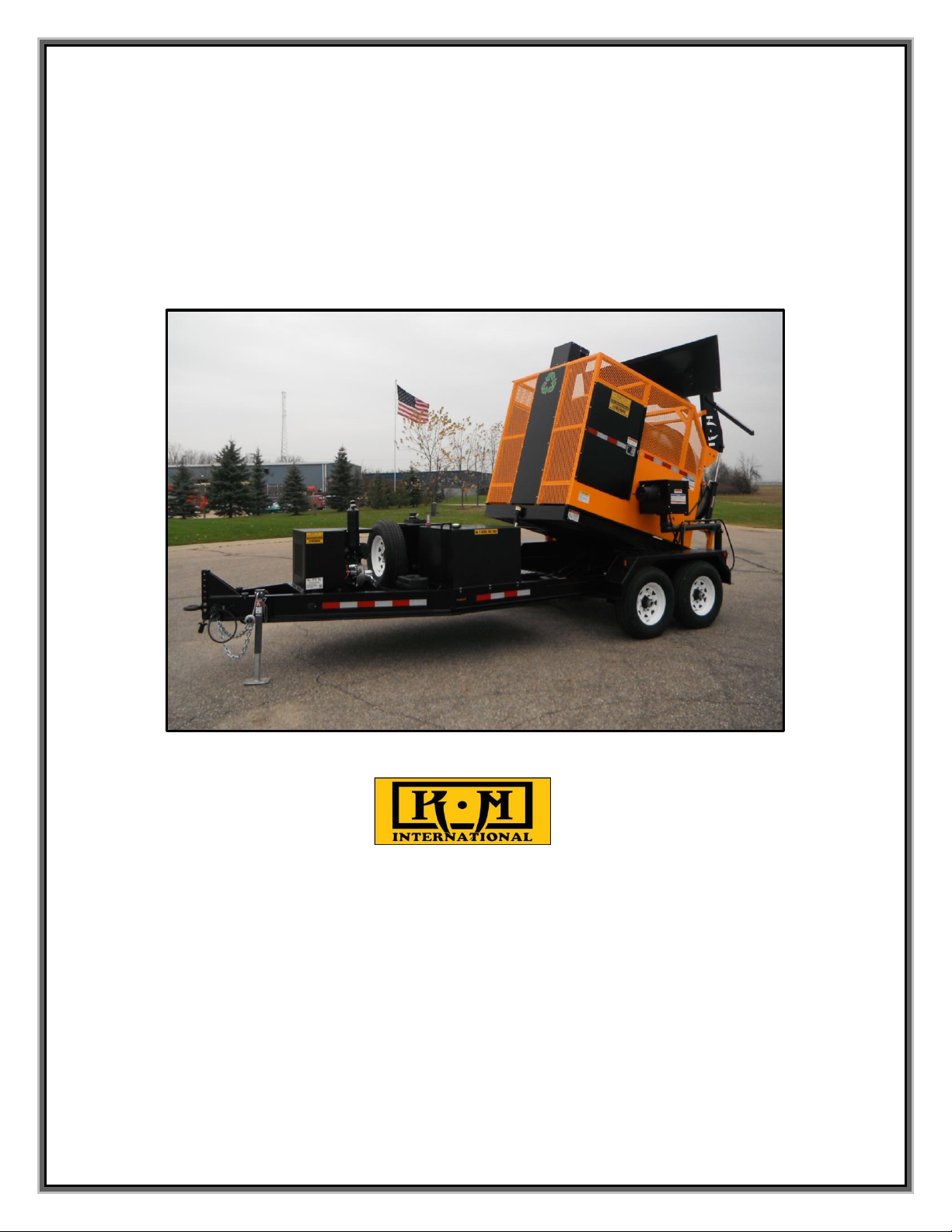

THE KM T2 IS A TRAILER UNIT

NOTICE: It is necessary to learn and know all applicable Department of

Transportation regulations prior to towing this vehicle.

AXLE RATING: 7,000 LBS. (EACH)

GVWR: 14,000 LBS.

TIRES: 3,520 LBS. capacity each (load range E)

TIRE PRESSURE: 80 PSI cold inflation

BRAKES: 12V Electric; all four tires; safety breakaway feature

Optional: Hydraulic brakes; all four tires

WARNING: Use of a tow vehicle with a towing capacity less than the load rating of

the trailer can result in loss of control, and may lead to death or serious injury. Ensure

your hitch and tow vehicle are rated for the Gross Vehicle Weight Rating identified on

the VIN tag of your trailer.

WARNING: Be sure that the tow hitch load rating meets or exceeds the GVWR of the

trailer. Inspect the tow hitch for wear. Replace if worn, cracked, or corrosion exists.

Inspect and ensure that all connecting hardware is tightened and serviceable.

NOTICE: When connecting the tow vehicle to the trailer ensure to match the tow

hitch and trailer hitch size. Inspect that the hitch is securely coupled and safety chains

are properly attached before travel.