9/27/2005 VERSION 4.0 4

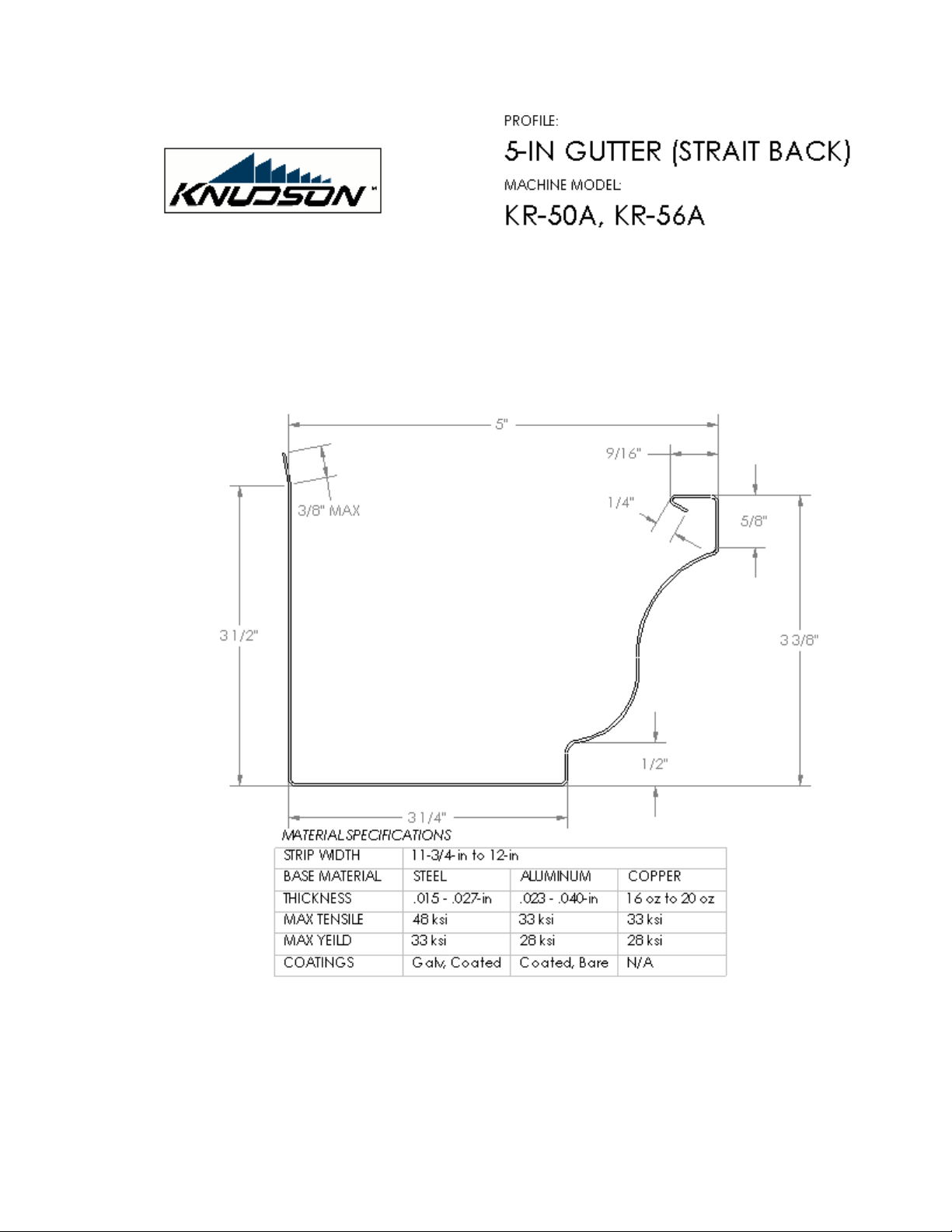

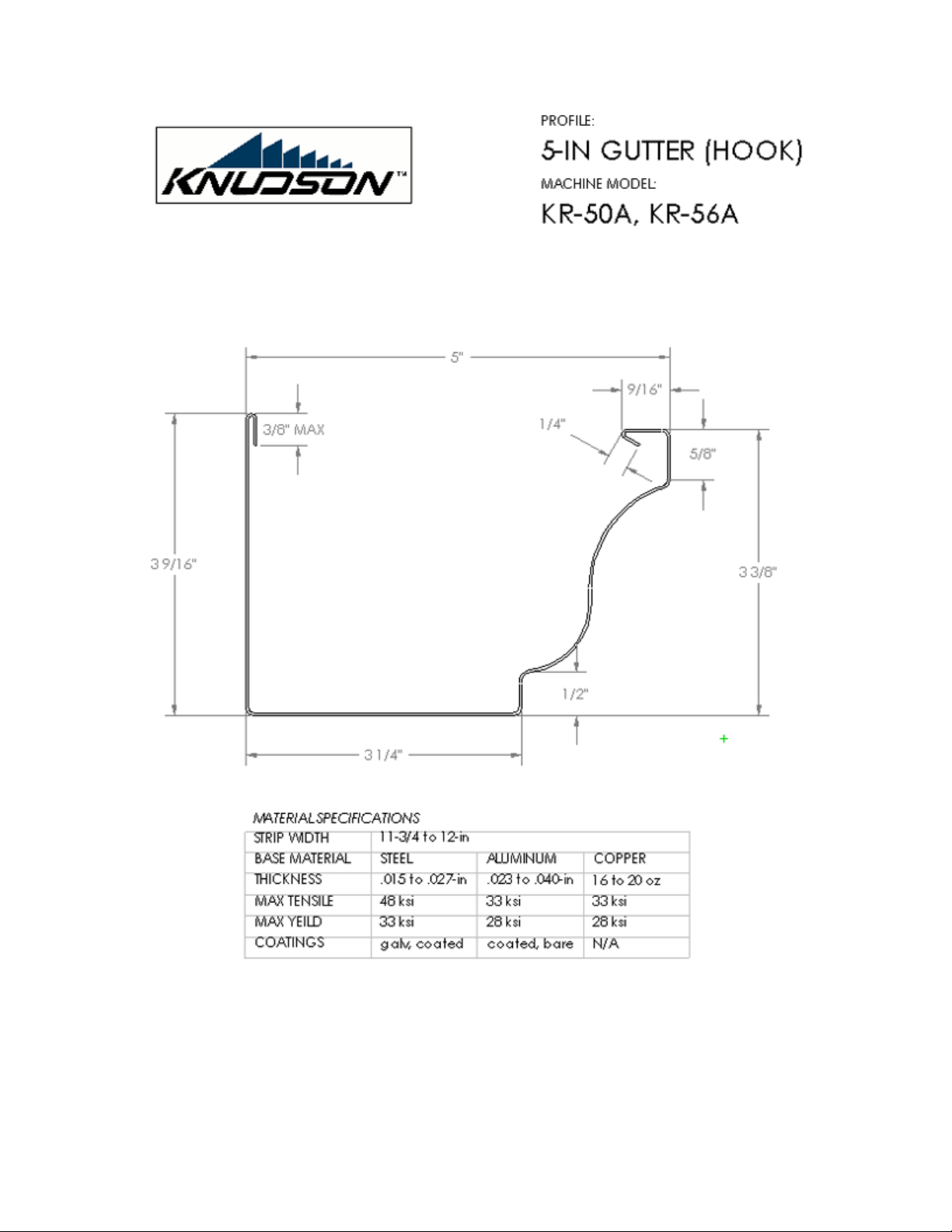

1. PROFILE SPECIFICATIONS

1.1. PROFILE SPECIFICATIONS

1.1.1. Profiles

Refer to the enclosed profile drawings at the end of this Section:

5-in K-Style OG Gutter with Straight Back (KR-50A, KR-56A)

5-in K-Style OG Gutter with Free Float Hook (KR-50A, KR-56A)

5-in K-Style OG Gutter with 1-in Flange (KR-50A, KR-56A)

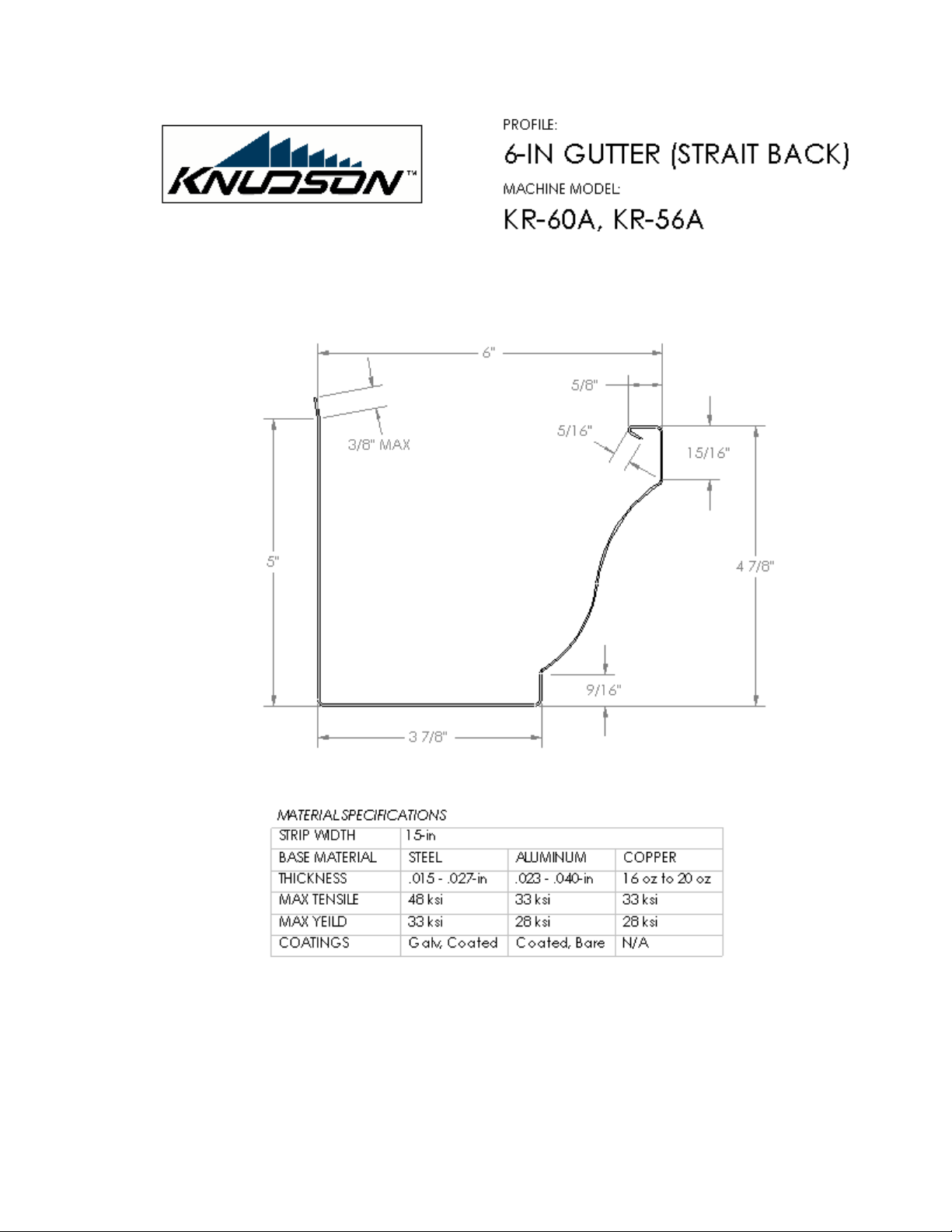

6-in K-Style OG Gutter Straight Back (KR-60A, KR-56A)

6-in K-Style OG Gutter with Free Float Hook (KR-60A, KR-56A)

6-in K-Style OG Gutter with 1-in Flange (KR-60A, KR-56A)

6-in K-Style OG Gutter with 2-in Flange (KR-60A, KR-56A)

1.1.2. Material Types

Steel, Galvanized Steel, Pre-finished/Coated Steel

Aluminum, Coated Aluminum

Copper

1.1.3. Material Thickness

Steel - .015-in (.38mm) to .027-in (.68mm)

Aluminum - .023-in (.57mm) to .040-in (1.02mm)

Copper - 16oz (.53mm) to 20oz (.69mm)

1.1.4. Material Strength

STEEL

Maximum Tensile Strength = 48 ksi (330 MPa)

Maximum Yield Strength = 33 ksi (230 MPa)

(ASTM A611 Grade C or equivalent)

ALUMINUM/COPPER

Maximum Tensile Strength = 33-ksi (227-Mpa)

Maximum Yield Strength = 28-ksi (193-Mpa)

1.1.5. Strip Width (Stretch-Out)

11 ¾-in (298mm) to 12-in (304mm) [5-in profiles]

15-in (381mm) [6-in profiles]

1.1.6. Profile Dimensions

Refer to the enclosed profile drawings at the end of this Section. All shown dimensions are nominal profile

dimensions.