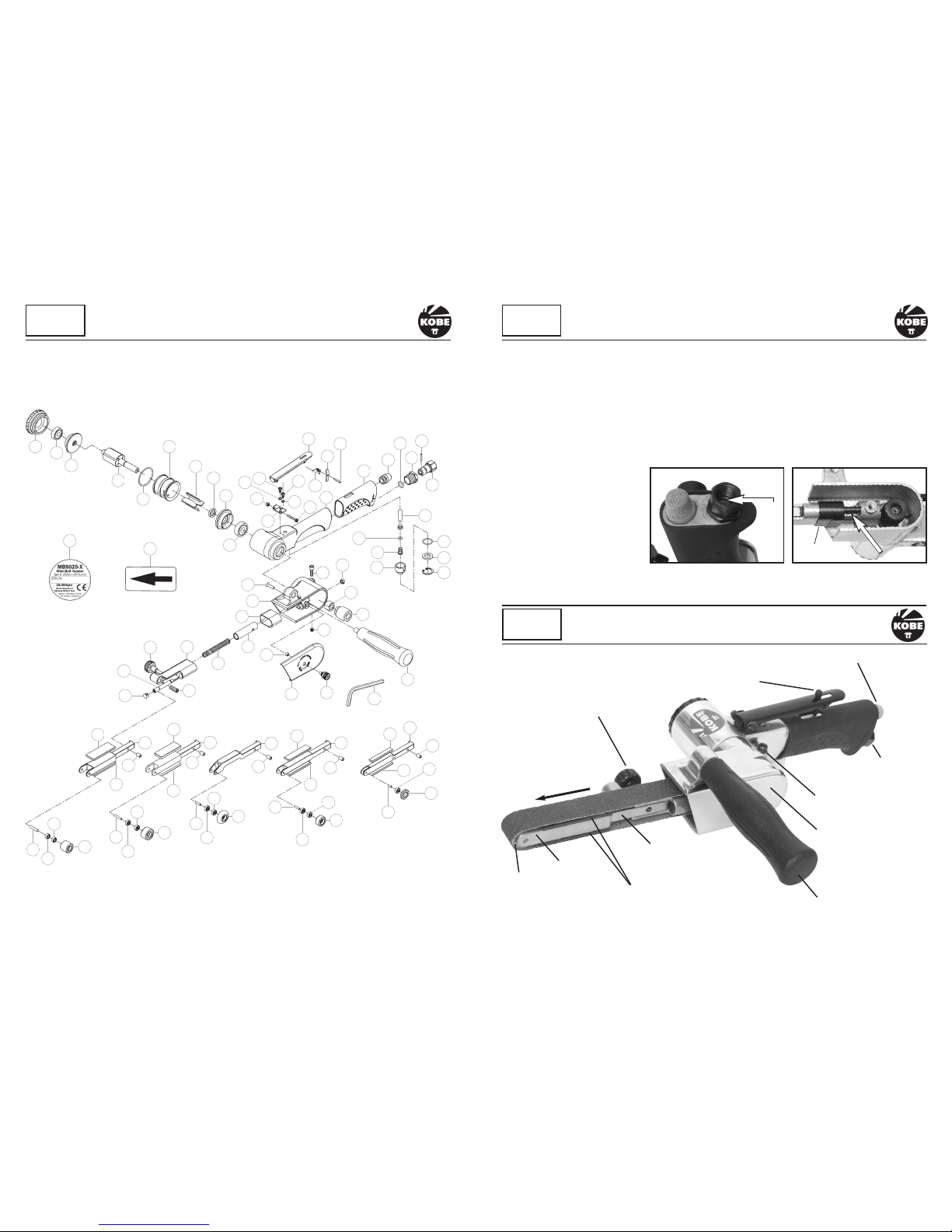

4 9

MODEL NUMBER ..........................MBS025-X

BELT SIZE......457 (18”) x 6, 10, 13 & 20mm

FREE SPEED................................18,000rpm

AIR INLET THREAD ...........................1/4” NPT

MINIMUM AIR HOSE SIZE (ID) ....10mm (3/8”)

AIR PRESSURE.......................6.2bar (90psi)

MOTOR POWER ..................................0.6hp

AIR CONSUMPTION

1

...........113Ltr/m (4cfm)

SOUND POWER LEVEL

2

......................92dBA

SOUND PRESSURE/NOISE LEVEL

2

......84dBA

VIBRATION LEVEL

3

..........................0.8m/s2

OVERALL LENGTH ............................390mm

NET WEIGHT.....................................1.36kg

1

Air consumption without load in 1 minute.

2

Per Pneurop Standard EN ISO 15744:2002.

3

Per EN 28662-1 and EN 28662-8.

KOBE

INDUSTRIAL

AIR TOOLS

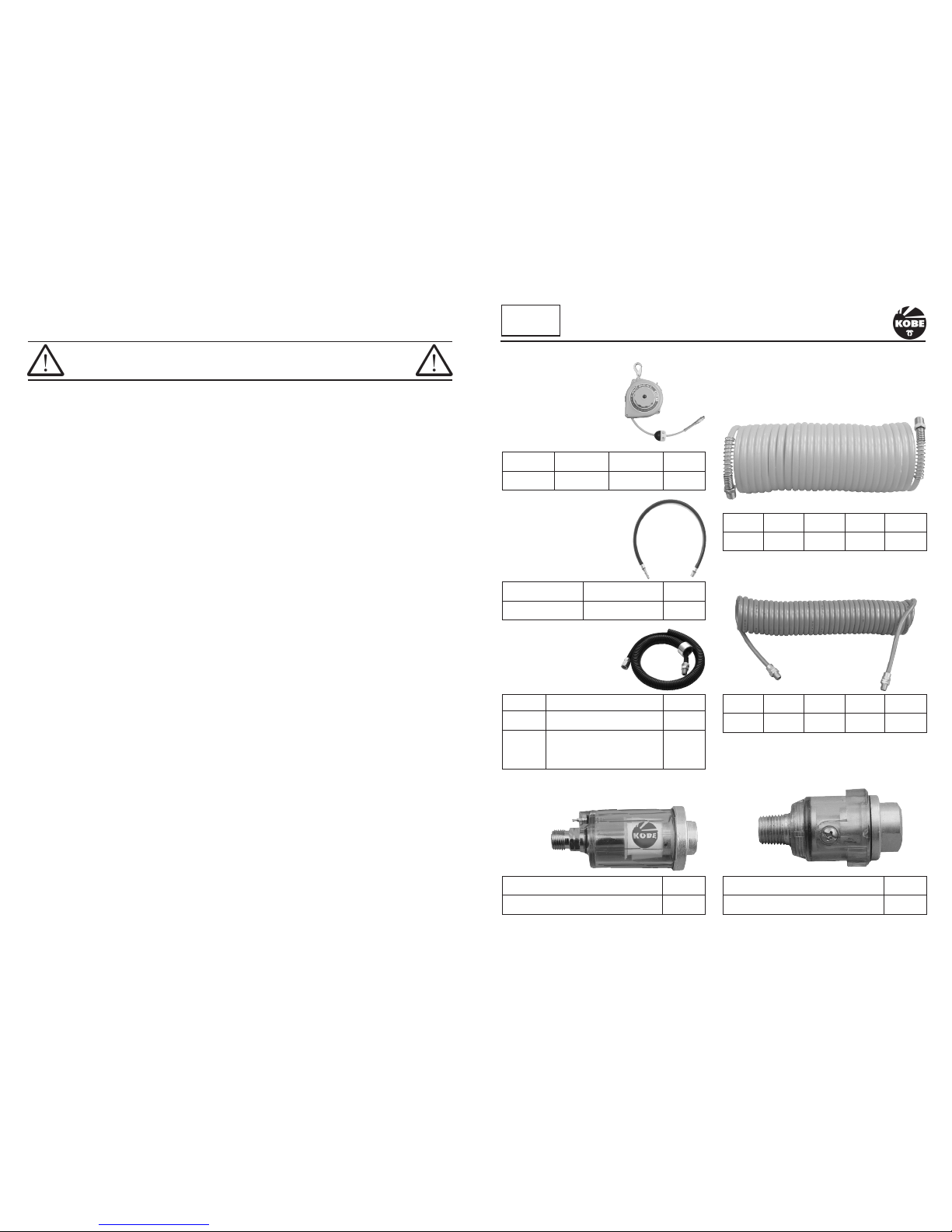

SPARE PARTS BREAKDOWN

Continued

KOBE

INDUSTRIAL

AIR TOOLS

SPECIFICATIONS

KOBE

INDUSTRIAL

AIR TOOLS

SUGGESTED AIR SUPPLY

KOBE

INDUSTRIAL

AIR TOOLS

UNPACKING & CASE CONTENTS

Before connecting, ensure the dust cap is removed (See page 6 for further details).

Connect tools to the air line using pipe, hose and fitting sizes listed in the specifications.

Supply tools with 6.2bar (90psi) of clean, dry air. A higher pressure and unclean air will shorten the tool life

because of faster wear and may create a hazardous condition.

Requirements for Quick Acting Couplings connected to Air Tools:

A whip hose of minimum length 500mm between the tool and the coupling is required in order to comply

with Health and Safety Executive Guide HS(G) 39, BS4575:2, ISO 4414 and ISO 6150. This will also

reduce the strain applied by the weight of the air hose on the end of the air tool.

>500mm

WHIP HOSE

WHIP HOSE

ADAPTOR

TAILPIECE

ADAPTOR

OILER

TAILPIECE

TAILPIECE

STOP VALVE PIPES AND

FITTINGS

REGULATOR

COUPLING

OIL DAILY HERE

COUPLING

FILTER

MAIN HOSE DRAIN DAILY

AIR SUPPLY

It is recommended that the packaging materials (plastic bags, polystyrene, cable ties etc.) are saved for future

transportation of the tool in the event of it requiring service or repair. If you decide not to keep them, they must

be disposed of in an appropriate refuse collection container. These materials must not be left within the reach

of children as they are potential sources of danger.

Make sure the tool is in perfect condition and that there are no visible damaged parts. If in doubt, do not use

the tool and contact your local Kobe agent from whom it was purchased.

I x Mini Belt Sander

MBS025-X with

20mm contact arm

I x 4mm

hexagon key

L-wrench I x 6mm contact arm

I x 10mm contact arm

I x 13mm contact arm

I x 10mm offset contact arm

1 . . .KBE-298-5200A........Housing

2. . .KBE-298-5201B .......Screw (M4x25L)

3. . .KBE-298-5202C .......Air inlet

4. . .KBE-298-5203D .......Throttle lever

5. . .KBE-298-5204E........Valve stem

6. . .KBE-298-1184S .......Valve

7. . .KBE-298-0016S .......“O” ring (3.9x1.9)

8. . .KBE-298-5207H .......Spring

9. . .KBE-298-1193S .......“O” ring (14.5x1.5)

10 . .KBE-298-1196S .......Spacer

11 . .KBE-298-1199S .......Retaining ring (RTW-18)

12 . .KBE-298-1373S .......Spacer

13 . .KBE-298-5143W.......Screw (M5x16L)

14 . .KBE-298-1376S .......Rear end plate

15 . .KBE-298-5214Q .......Rotor

16 . .KBE-298-1382S .......Rotor blade (4)

17 . .KBE-298-5216S .......Screw

18 . .KBE-298-1388S .......Cylinder

19 . .KBE-298-1391S .......Front end plate

20 . .CES-298-6001B .......Ball bearing (6000zz)

21 . .KBE-298-1394S .......Cap

22 . .KBE-298-5221Y........Drive wheel

23 . .KBE-298-5222Z........Nut

25 . .KBE-298-5224A........Hex nut

26 . .KBE-298-5225B .......Grip

27 . .KBE-298-5226C .......Guide post

28 . .KBE-298-5227D .......Support rod

29 . .KBE-298-5228E........Screw (M4x16L)

30 . .KBE-298-5229F........Spring

31 . .KBE-298-5230G .......Tension arm

32 . .KBE-298-5231H .......Handle

33 . .CES-298-0609B .......Ball bearing (608zz)

34 . .KBE-298-5233K .......Screw thread inserts

. . . . ...............................(M5x0.8x1D)

35 . .KBE-298-1112S .......Muffler

36 . .KBE-298-5235M.......Spring

37 . .KBE-298-5236N .......Guard

38 . .KBE-298-5237P........Ball bearing (2) (684zz)

39 . .KBE-298-5238Q .......Knob

40 . .KBE-298-5239R .......Safety bar

41 . .KBE-298-5240S .......Spring

42 . .KBE-298-3634S .......Spring pin (2x18L)

43 . .KBE-298-5242V........20mm Platen pads (2)

44 . .KBE-298-5243W.......Plug

45 . .KBE-298-5244X........18mm Platen pads (2)

46 . .KBE-298-5245Y........Dust cover

47 . .KBE-298-5246Z........Screw thread inserts

. . . . ...............................(#8-32UNCx1D)

49 . .KBE-298-5248A........13mm Platen pads

50 . .KBE-298-5249B .......20mm Contact arm

51 . .KBE-298-5250C .......13mm Contact arm

52 . .KBE-298-5251D .......10mm Contact arm

53 . .KBE-298-5252E........10mm Contact arm

54 . .KBE-298-5253F........6mm Contact arm

55 . .KBE-298-5254G .......Idle pulley

56 . .KBE-298-5255H .......Idle pulley

57 . .KBE-298-5256J ........Idle pulley

58 . .KBE-298-5259K .......Idle pulley

59 . .KBE-298-5258L........Idle pulley

60 . .KBE-298-1973S .......Pin (4x19.8L)

61 . .KBE-298-5727D .......Pin (3x17.8L)

62 . .KBE-298-5261P........Pin (2) (3x12.8L)

63 . .KBE-298-5262Q .......Pin (3x7.8L)

64 . .KBE-298-5263R .......Guard body

65 . .KBE-298-5264S .......Ball bearing (7) (623zz)

66 . .KBE-298-5265T........8mm Platen pads (2)

67 . .KBE-298-5266V........Screw thread inserts

. . . . ...............................(5) (#8-32UNCx2D)

68 . .KEN-601-1400K .......Hexagon key L- wrench

. . . . ...............................(4mm)

69 . .KBE-298-5268X........“O” ring (7.5x1.5)

70 . .KBE-298-5726C .......Screw

71 . .KBE-298-5724A........Pin (2x13.8)

72 . .KBE-298-5272A........Screw (2) (M4x8L)

73 . .KBE-298-5273B .......Spring washer (2) (M4)

74 . .KBE-298-5274C .......Nut (M4)

75 . .KBE-298-5275D .......Lever support

76 . .KBE-298-5276E........“O” ring (26.7x1.78)

77 . .KBE-298-5277F........Specification label

78 . .KBE-298-9900A........Warning label 40x20mm

. . . .KBE-298-9460S .......Blow moulded case

. . . .KBE-280-5650K .......Optional 25mm contact

. . . . ...............................arm (Not included)

No. Order Code Description No. Order Code Description