NBK

page 6 NBK K01/0906

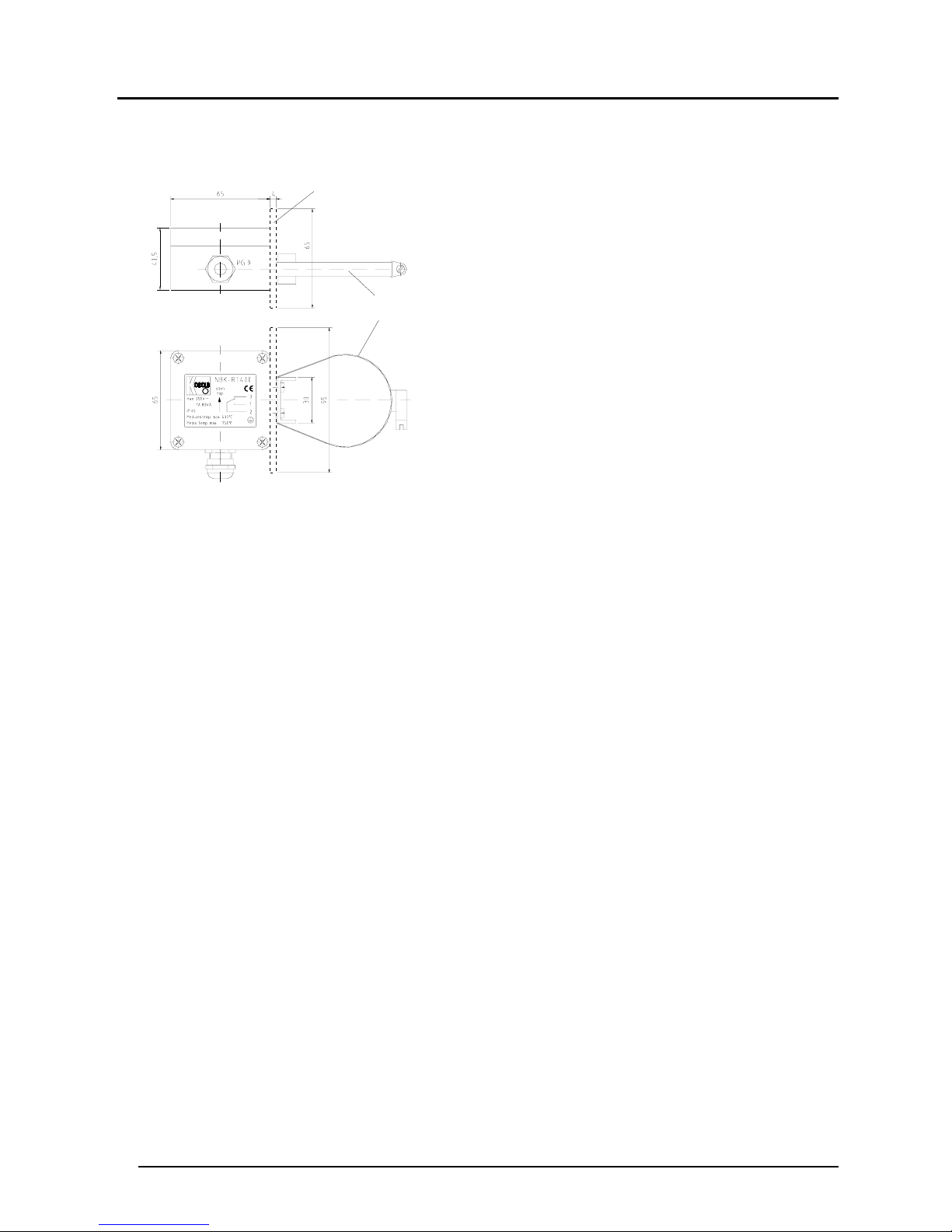

Magnetic roller indicator

As the float passes by, the red/white rollers are rotated in succession by 180°

around their own axes. The rollers change from white to red as the level rises and

from red to white as the level falls. The level in a tank or a mixer is continuously

displayed as a red column, even when the power fails.

Transmitter

To remotely transmit the level a transmitter with a chain of resistors or a magne-

tostrictive transducer can be mounted outside the bypass tube.

The contacts of a reed contact chain are connected or disconnected via the float

movement in a non-contacting manner. Depending on the level, the number of

connected resistors changes and as a consequence the output of the total

resistor value.

A continuous standard signal of 4 to 20 mA is generated by means of a fitted

transmitter. This standard signal can then be displayed on analogue or digital

indicating devices.

Universal indicating unit

A universal indicating unit of type series ADI can be mounted on the bypass to

display and evaluate the standard signal (4–20 mA) generated by the transmitter.

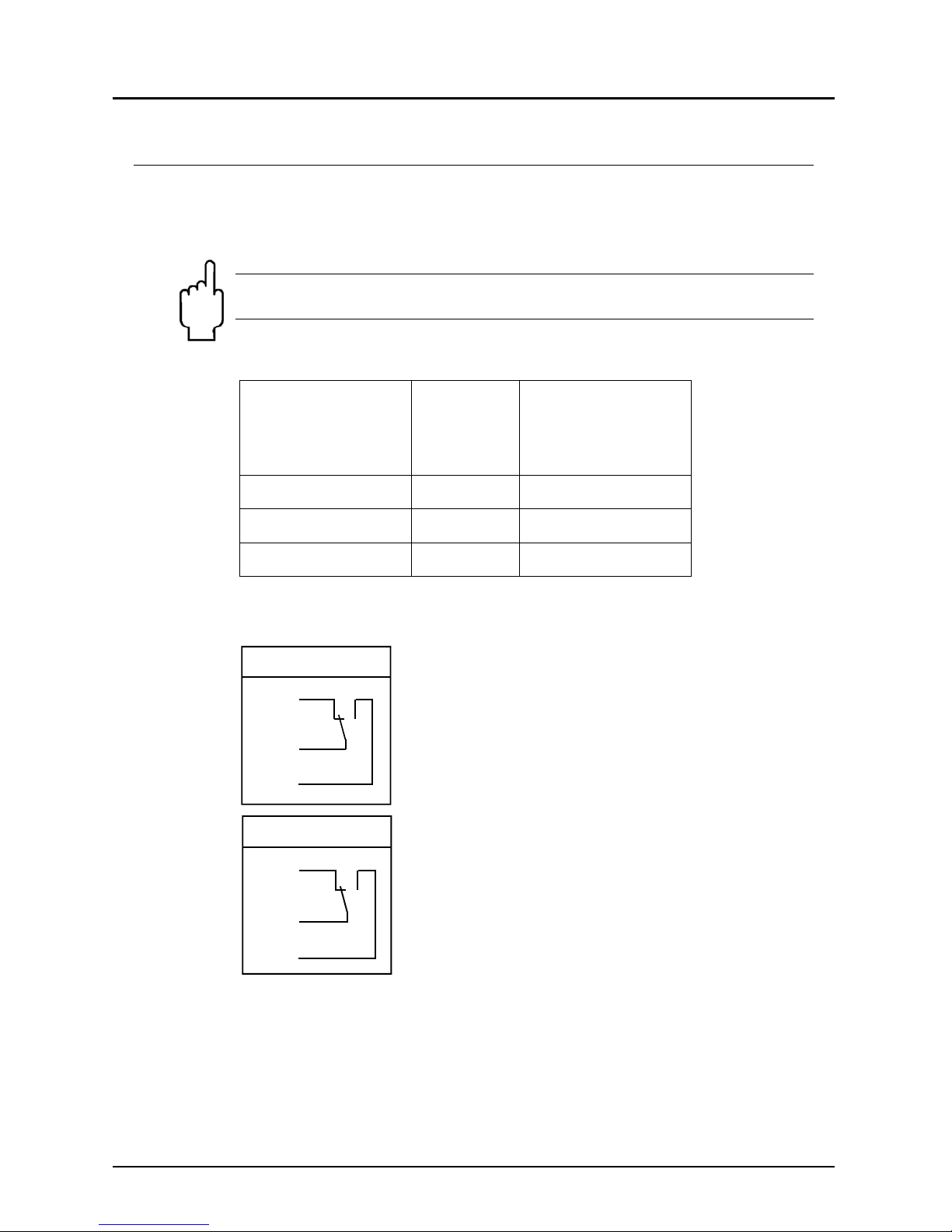

Limit contacts

One or more reed contacts for limit-value acquisition or also for level control can

be attached to the bypass tube.

ATEX version

The bypass level indicators can be supplied with ATEX approval. As an option

limit contacts and a reed contact chain with ATEX approval are available for level

measurement and monitoring.

ATEX approval:

Bypass-level indicator: Ex II 1G /2GD (mechanical)

Limit contact NBK-RA: Ex II 2G EEx m II T6 / T5

Immersible magnetic probe

(Reed contact chain): Ex II 1G EEx ia IIC T6

Transmitter for Reed chain: Ex II (1) G [EEx ia] IIC

GL version

In the pressure stages PN 16 (NBK-03) and PN 40 (NBK- 06) the bypass level

indicators are available with GL approval (Germanischer Lloyd). The magnetic

roller indication as well as limit contacts and a reed contact chain can be

delivered for level indication and evaluation .

Certificate-No. GL: 79 786-95 HH