MFR-00

page 4 MFR-00 K01/0913

5. Operating Principle

KOBOLD magnetic filters are used in many applications, including central system

filters, where it is necessary to protect devices from dirt and contamination. They

are used to catch and remove contaminants from industrial cooling and

lubrication circuits, especially where residue and sediment from assembly (such

as chips from thread-cutting) and normal operation (such as scale and residue

from frictional wear) can be carried along in the medium being filtered.

Contaminants of these types can form deposits that can cause pitting and

corrosion in highly sensitive measuring and control devices. Regular

maintenance and cleaning of the magnetic filter inserts will effectively prevent

system and device failure and the resulting downtime.

6. Mechanical Connection

Before mounting:

•Remove all transport safety devices. Observe that there won’t be any parts of

the package in the armature.

•Satisfy yourself that the armatures/vales will only be used within their

admissible limiting value (see technical data).

•After the mechanical connection check the tightness of the connection screw

connection/tube, if possible.

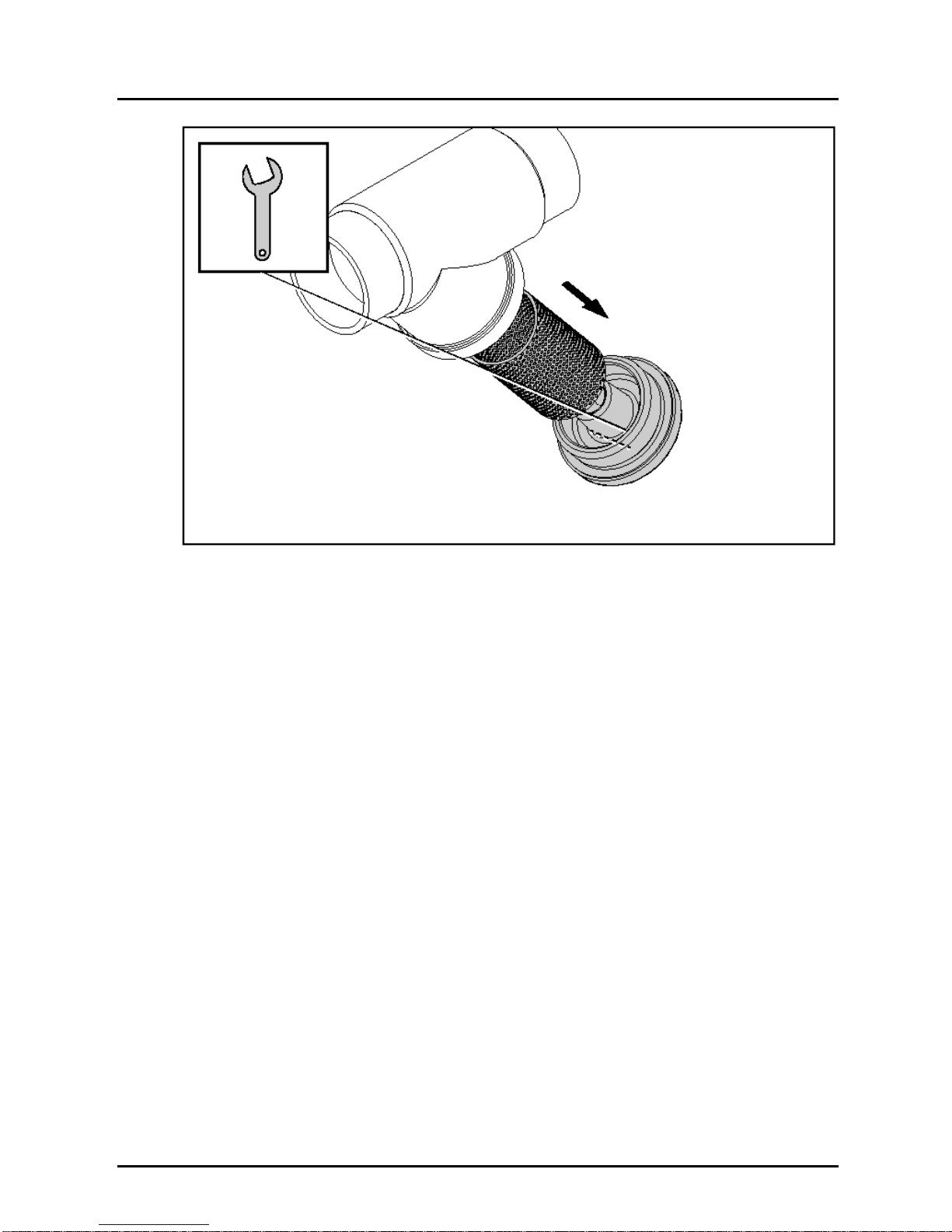

6.1 Mounting/Disassembly

The mechanical mounting is identical in all variants. It differs only by the type of

connection.

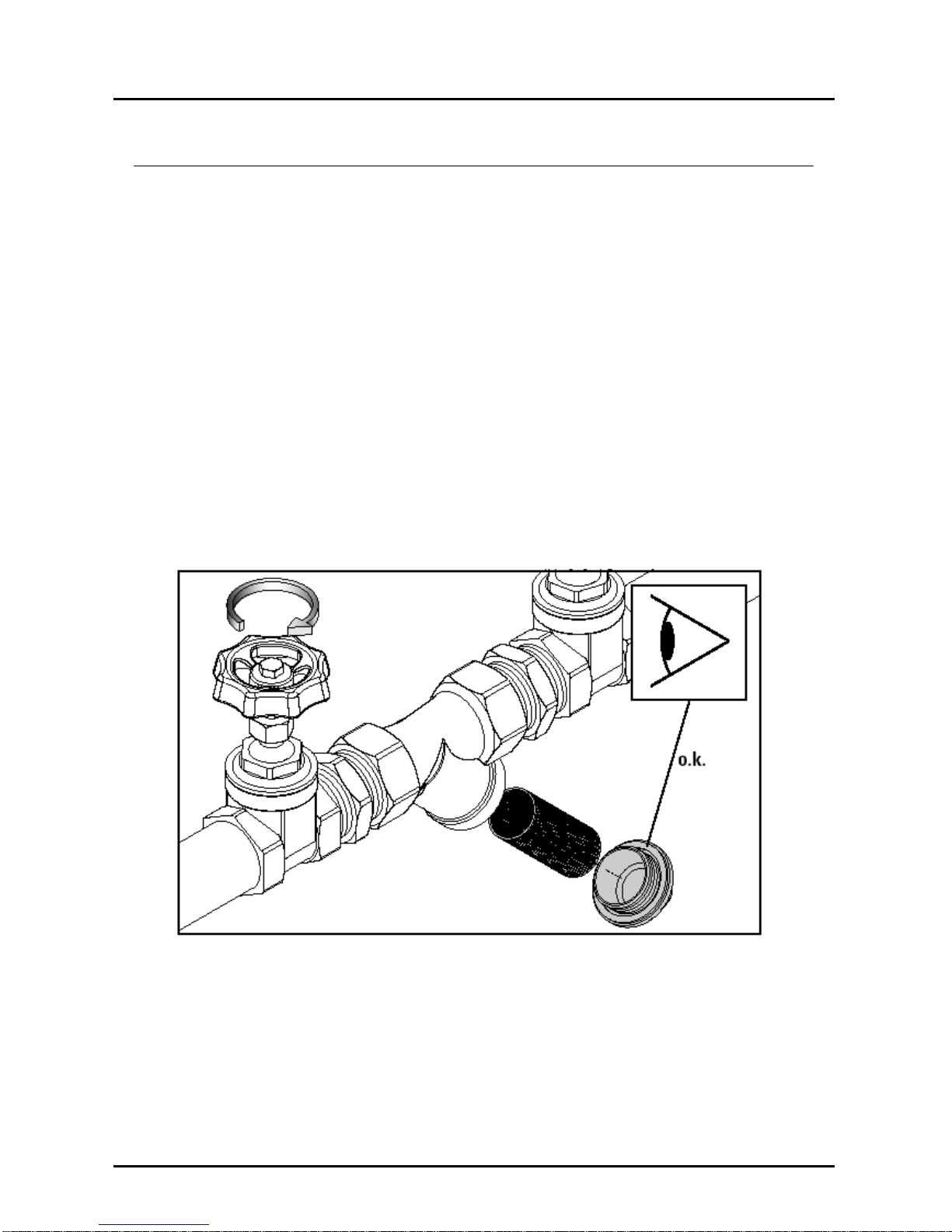

Observe the flow direction which is specified on the valve body. The installation

of the screw joint should take place downwards, that the pollution will fall out of

the body by the cleaning of the y-strainer.

We recommend the installation of a gate valve in front and behind the y-strainer,

to clean the mesh without emptying of the device.

Remove all transport safety devices (e.g. plugs or caps). Observe that there

won’t be any parts of the package or other pollution in the armature.

Before mounting the y-strainer clean up the pipes.

Avoid stress on the body by non align pipes.