Kockum Sonics AB, Industrigatan 39, P.O. Box 1035, SE-212 10 Malmö, Sweden, Tel: +46 (0) 40 671 88 00

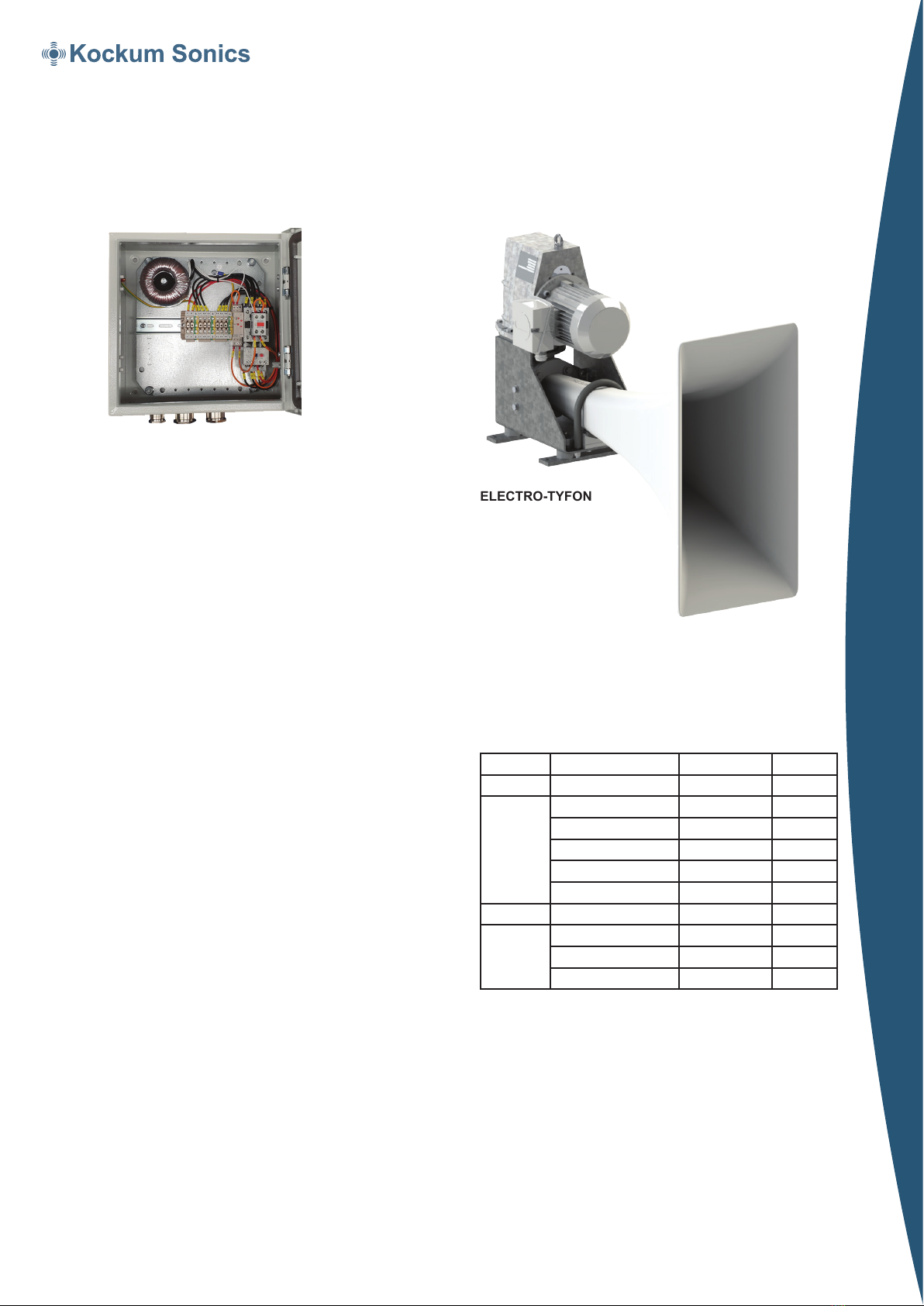

ELECTRO–TYFON®MT 150/130

For vessels of 75 m to 200 m in length

TYFON®

KSM520E/2220

Contactor Unit TK 80

See separate leaflet KSM742

Sound frequency (basic): 130 Hz

Sound Pressure Level

acc to IMO (1/3 oct band): >138 dB/1m

Sound Level A-weighted: 142 dBA/1m

Electrical protection class: IP 56

Colors:

Body Galvanized nat.

Motor Grey RAL 7030

Horn White RAL 9003

Weight (approx.): 68 kg

General Information

ELECTRO–TYFON®MT 150/130 is an electrically driven

piston ship’s whistle. It is built up of comparatively few

moving parts as the “swinging piston”, no lubricated cylinder

and an oil free gearbox.

Important features:

• unsymmetrical sound distribution

• operates in all ambient temperatures without any

additional measures

• unaected by voltage and frequency uctuations

• oil free, maintenance free and non–corrosive

• easy to install

• complies fully with the International Regulations

IMO 1972 Technical Data

ELECTRO-TYFON

Operates in all temperatures without any

additional measures

ELECTRO–TYFON®MT 150/130 will give a high

performance in both arctic and tropical climates.

A patented system with a high eciency rectangular

horn and a specially designed motor will match the motor

speed to the acoustic resonance of the horn at any

ambient temperature without any additional measures.

This system also prevents the whistle from being aected

by voltage and frequency uctuations in onboard mains.

Unsymmetrical Sound Distribution

The IMO Regulations stipulate a very high Sound

Pressure Level for ecient signaling, yet the sound level

of the vessel's own signal at the listening posts shall not

exceed 110 dBA.

A common way to solve this “paradox” is to place the

whistle very high above deck. But what if the highest point

is not high enough? For example: to reduce the noise

from the signal by 6 dB, the distance between the

listening post and the whistle must be doubled!

ELECTRO–TYFON®MT 150/130 with Unsymmetrical

Sound Distribution is the solution. The horn with its unique

vertically extended front, and a specially created sound

spectrum will reduce the noise on deck with 6–8 dB

compared to a conventional whistle with circular orice.

Type Power Supply Rated current Ref. No.

MT150/130 3ph440V60Hz(+-10%) 11A 24800171

3ph230V60Hz(+-10%) 20A 24800935

3ph380V50Hz(+-10%) 11,5A 24800498

3ph230V50Hz(+-10%) 22A 24800936

3ph690V60Hz(+-10%) 5,5A 24800543

3ph690V50Hz(+-10%) 6 A 24800544

MT150/140 3ph440V60Hz(+-10%) 11A 24800569

3ph380V50Hz(+-10%) 20A 24800570

3ph690V60Hz(+-10%) 5,5A 24800571

3ph690V50Hz(+-10%) 6A 24800572