Product Information (cont.)

Electrical Requirements

The installation must have two Ground-Fault Circuit-Interrupters (GFCI) or Earth-Leakage Circuit-Breakers

(ELCB). The GFCI or ELCB protects against line-to-ground shock hazard. Use a 220-240 V, 20 A, 50/60 Hz

dedicated service for the pump and control. Use a separate 220-240 V, 20 A, 50/60 Hz dedicated service for

the heater.

Table of Contents

Important Information .............................................................. 2

Product Information ............................................................... 2

Product Modifications ............................................................ 2

Product Inspection .............................................................. 2

Factory-Assembled Features ...................................................... 2

Connections and Service Access ................................................... 2

Electrical Requirements .......................................................... 3

Before You Begin ................................................................. 4

Tools and Materials ............................................................... 4

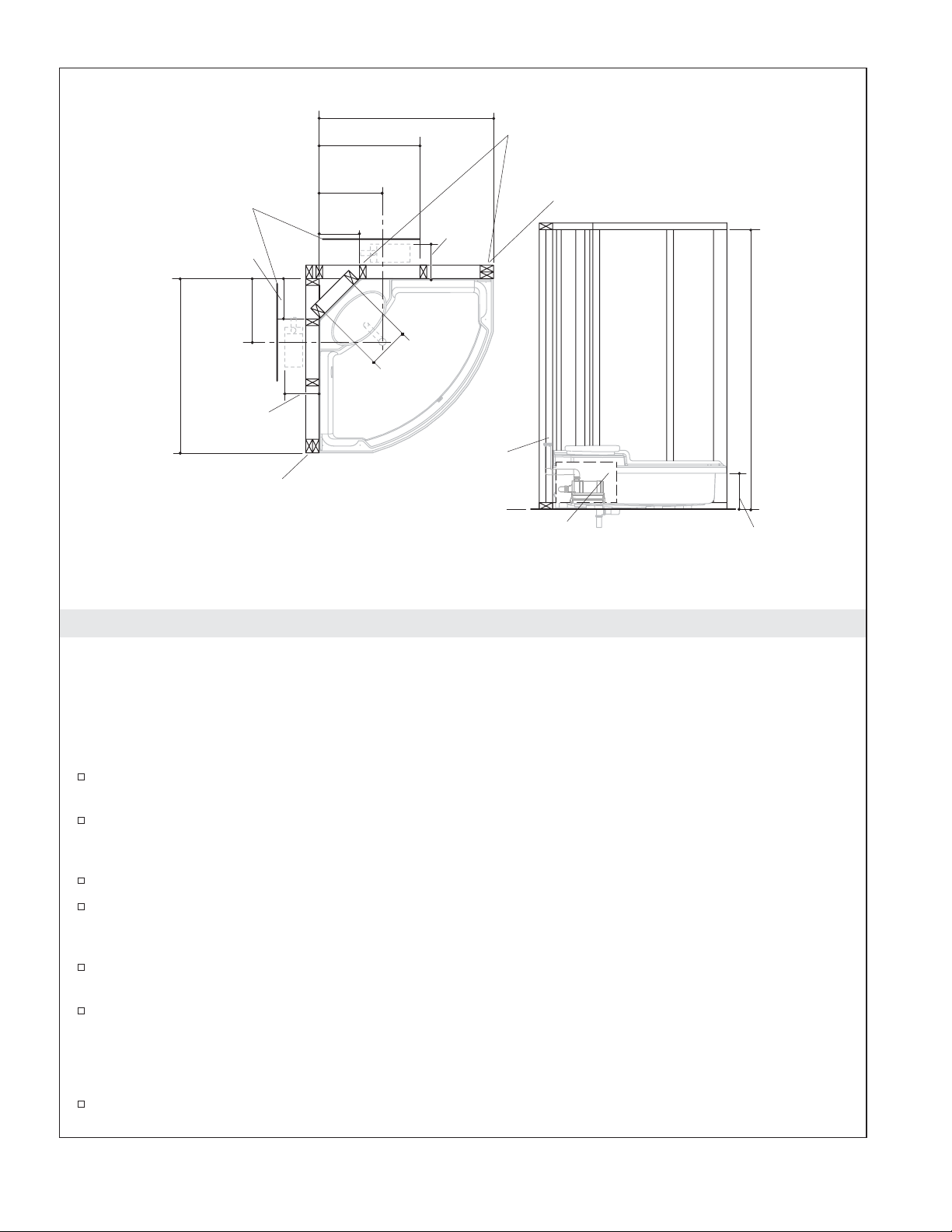

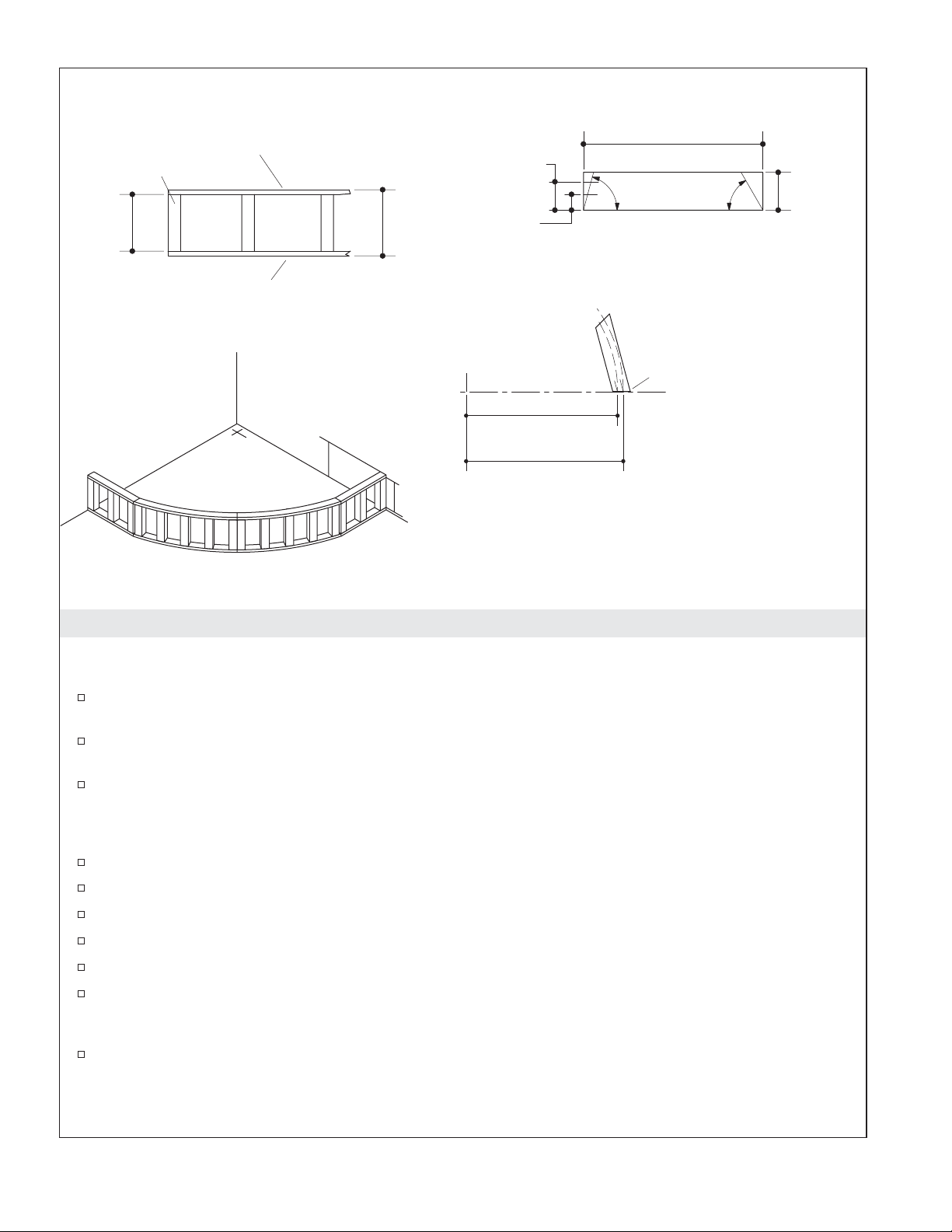

Framing Preparation .............................................................. 5

Plumbing Preparation .............................................................. 6

Install the Footbath ............................................................... 6

Construct the Apron ............................................................... 7

Install Plumbing .................................................................. 8

Tower Mounting Frame Preparation ................................................... 8

Install the Tower Mounting Frame ..................................................... 8

Connect the Suction Assembly ....................................................... 9

Connect the Tower and Pump ...................................................... 10

Make Electrical Connections ........................................................ 11

Install the Wall Jambs ............................................................ 13

Apply Silicone Sealant ............................................................ 13

Complete the Finished Wall ........................................................ 14

Install the Side Panels ............................................................ 15

Install the Header ................................................................ 15

Secure the Side Panels ........................................................... 16

Set the Header Height ............................................................ 17

Hang the Door Panels ............................................................ 18

Adjust Header Height ............................................................. 19

Install the Side Jamb Seals ........................................................ 20

Adjust the Side Door Panels ........................................................ 20

Adjust the Center Door Panel ....................................................... 21

Install the Backstop .............................................................. 21

Install the Door Handles ........................................................... 22

Adjust the Stop Blocks ............................................................ 22

Apply Sealant to the Door ......................................................... 23

Install the Tower ................................................................. 25

Complete the Tower Installation ..................................................... 25

Faucets and Fittings .............................................................. 25

Install the Keypad ............................................................... 26

Install the Seat .................................................................. 27

Water Test the System ............................................................ 27

Clean Up After Installation ......................................................... 27

Troubleshooting Procedures ........................................................ 28

Kohler Co. 3 1032108-2-D