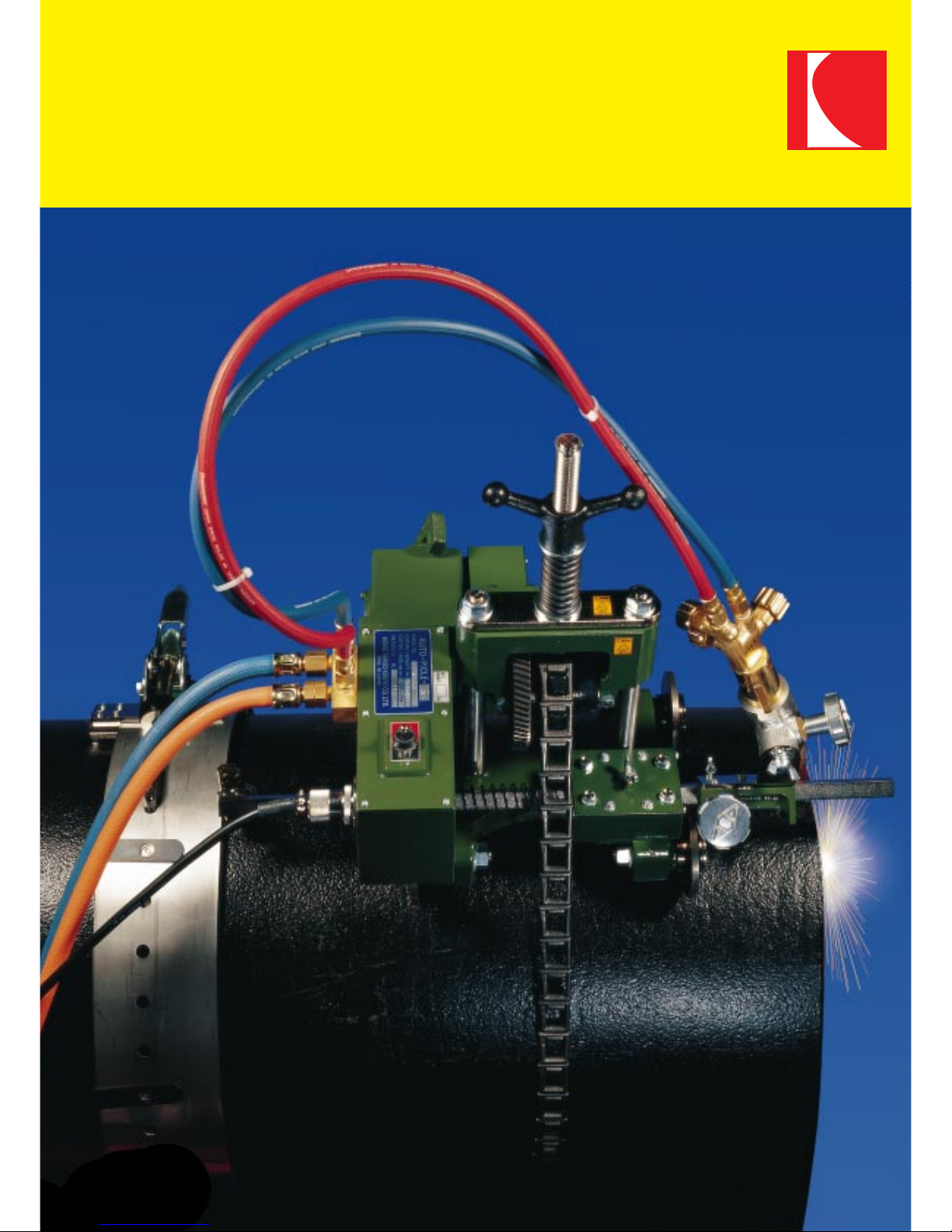

AUTO PICLE-S

1

CONTENTS

1 Safety information ......................................................................................... 5

1.1 Introduction ............................................................................................ 5

1.2 General machine safety precautions ..................................................... 5

1.2.1 Machine safety ............................................................................ 5

1.2.2 Safety clothing ............................................................................. 6

1.2.3 Electrical system precautions ...................................................... 6

1.2.4 Maintenance and inspection precautions .................................... 6

1.3 General Gas cutting safety precautions ................................................ 7

1.3.1 Prevention of explosion ............................................................... 7

1.3.2 Pressure regulator safety precautions ......................................... 7

1.3.3 High pressure gas cylinder safety precautions ............................ 7

1.3.4 Safety precautions for hoses .......................................................7

1.3.5 Safety precautions for fire ........................................................... 8

1.3.6 Safety precautions for skin burns ................................................ 8

1.4 Operating and handling safety precautions ...........................................9

2 Locations of safety labels ............................................................................ 11

3 Outline of machine ...................................................................................... 13

3.1 Features of machine ............................................................................ 13

3.2 Name and function of each section ..................................................... 14

3.3 Specifications ...................................................................................... 15

4 Preparation for operation ............................................................................ 17

4.1 Contents of package ............................................................................17

4.2 Machine assembly ...............................................................................18

4.3 Preparation for operation ..................................................................... 18

4.3.1 Connecting the power cable ...................................................... 18

4.3.2 Connecting the gas supply hose ...............................................19

4.3.3 Connecting the tip ..................................................................... 19

4.3.4 Determining the number of chains ............................................ 20

4.3.5 Securing machine to pipe .......................................................... 20

4.3.6 Assembling and mounting the guide rail ................................... 21

4.3.7 Trial operation ........................................................................... 23

5.1 Safety measures prior to operation .....................................................25

5.1.1 Grounding the machine ............................................................. 25

5.1.2 Selection of tip ........................................................................... 25

5.1.3 Operation of running direction changeover switch .................... 25

5.2 Ignition and flame adjustment .............................................................. 26

5.3 Cutting and piercing method ................................................................ 27

5.4 Safety measures against backfire and flashback ................................ 27

5.4.1 Prevention of backfire ................................................................ 27

5.4.2 Prevention of flashback ............................................................. 27

Auto Picle-S.book Page 1 Thursday, April 11, 2002 11:15 AM