4

Inspection procedure Perform in safe place without hazardous substance.

Maintenance and storage

lSpecifications

The values above represent the performance level with the use of standard

facepiece and without optional parts, etc.

*For cleaning, refer to “Cleaning after use.”

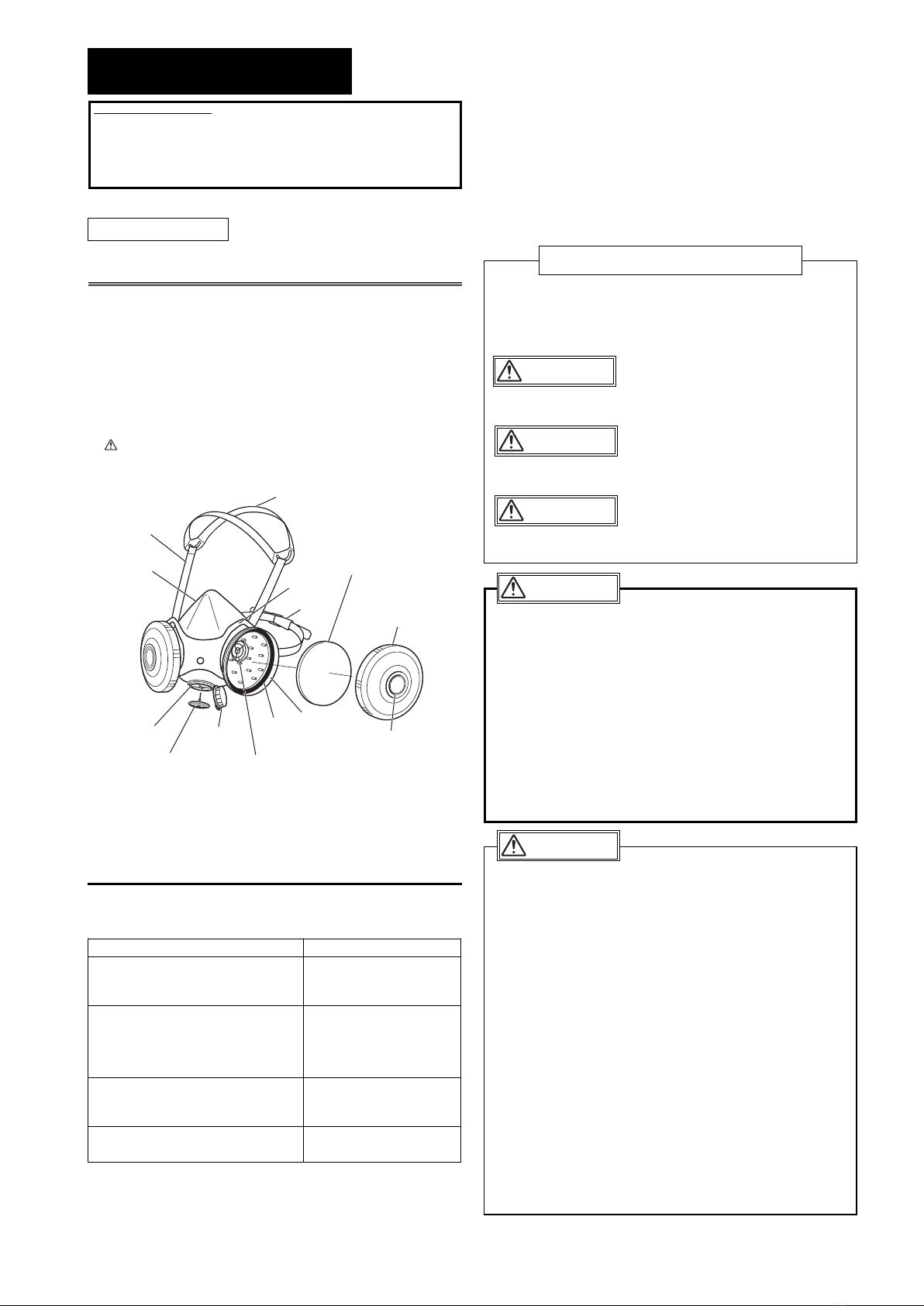

Replacement parts

Call Koken or local distributor to purchase the following replacement

parts.

lFiltering material -------1021 Mighty Micron Filter or

1021 Mighty Micron Filter-02 (2pcs/set per bag)

lInhalation valve --------Inhalation Valve Round Shape (Black)

(5pcs per bag)

Exhalation valve -------Exhalation Valve Type T-6K (5pcs per bag)

Exhalation valve cover

--

Exhalation Valve Cover Type T-6 (5pcs per bag)

Exhalation valve seat-Exhalation Valve Seat for T-6 (5pcs per bag)

Headband ---------------Headband Type RB (5pcs per bag)

Sponge-------------------Sponge Egg Shape (50pcs per package)

Facelet -------------------Facelet Type P (5pcs per bag)

Filter gasket-------------Filter Gasket Type 1021-II (10pcs per bag)

Filter cover --------------Filter Cover Type 1021-II (10pcs per bag)

Optional parts (sold separately)

●Fit tester for ensuring the fitness between respirator and face

---------------Fit Tester Type F (1set)

●Auxiliary filter to remove ozone odor

---------------1021KC Welder’s Ozone Filter for 1021R (5pcs per bag)

●Auxiliary filter to remove mercaptan odor

---------------1021KB Odor Filter for 1021R (5pcs per bag)

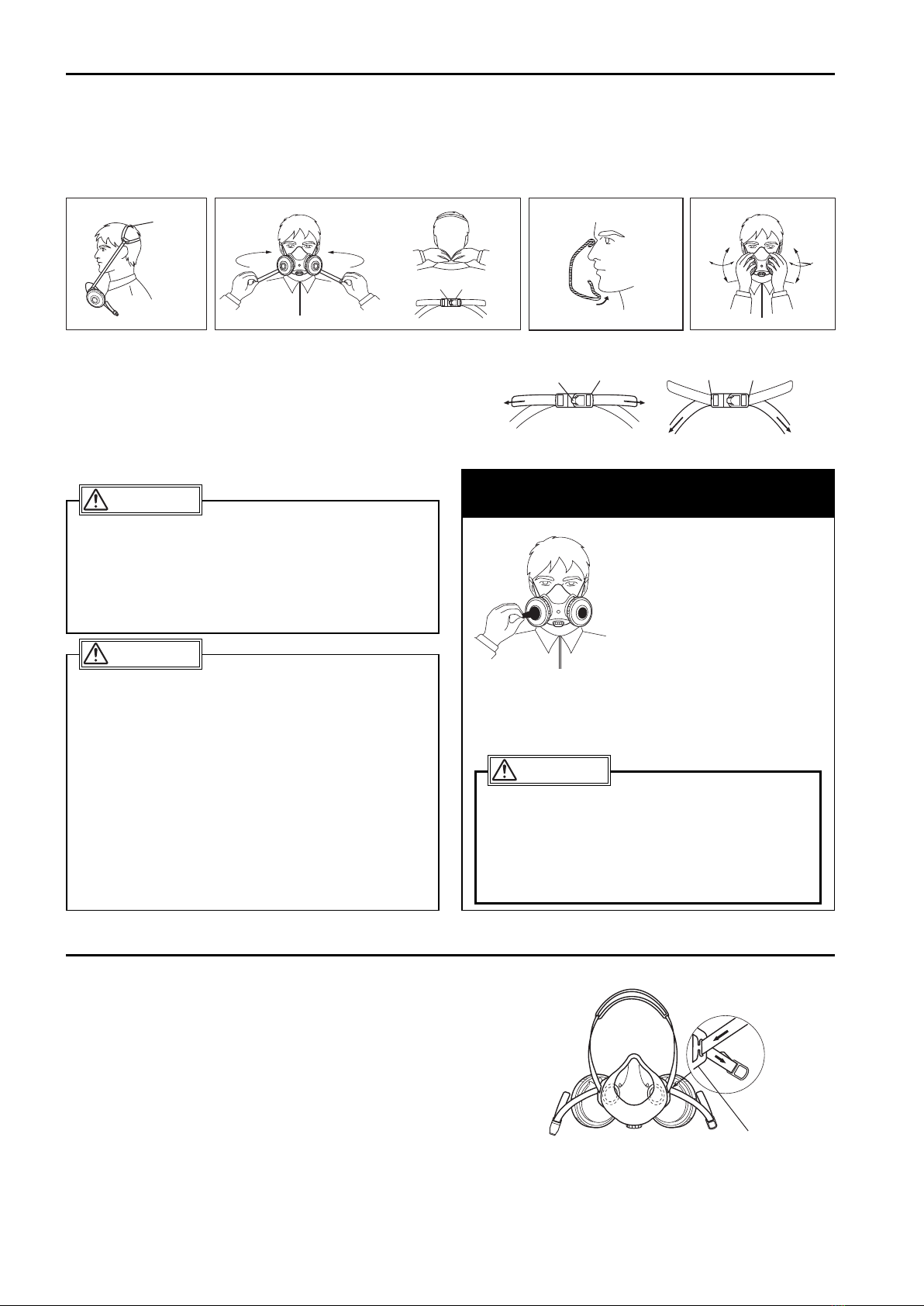

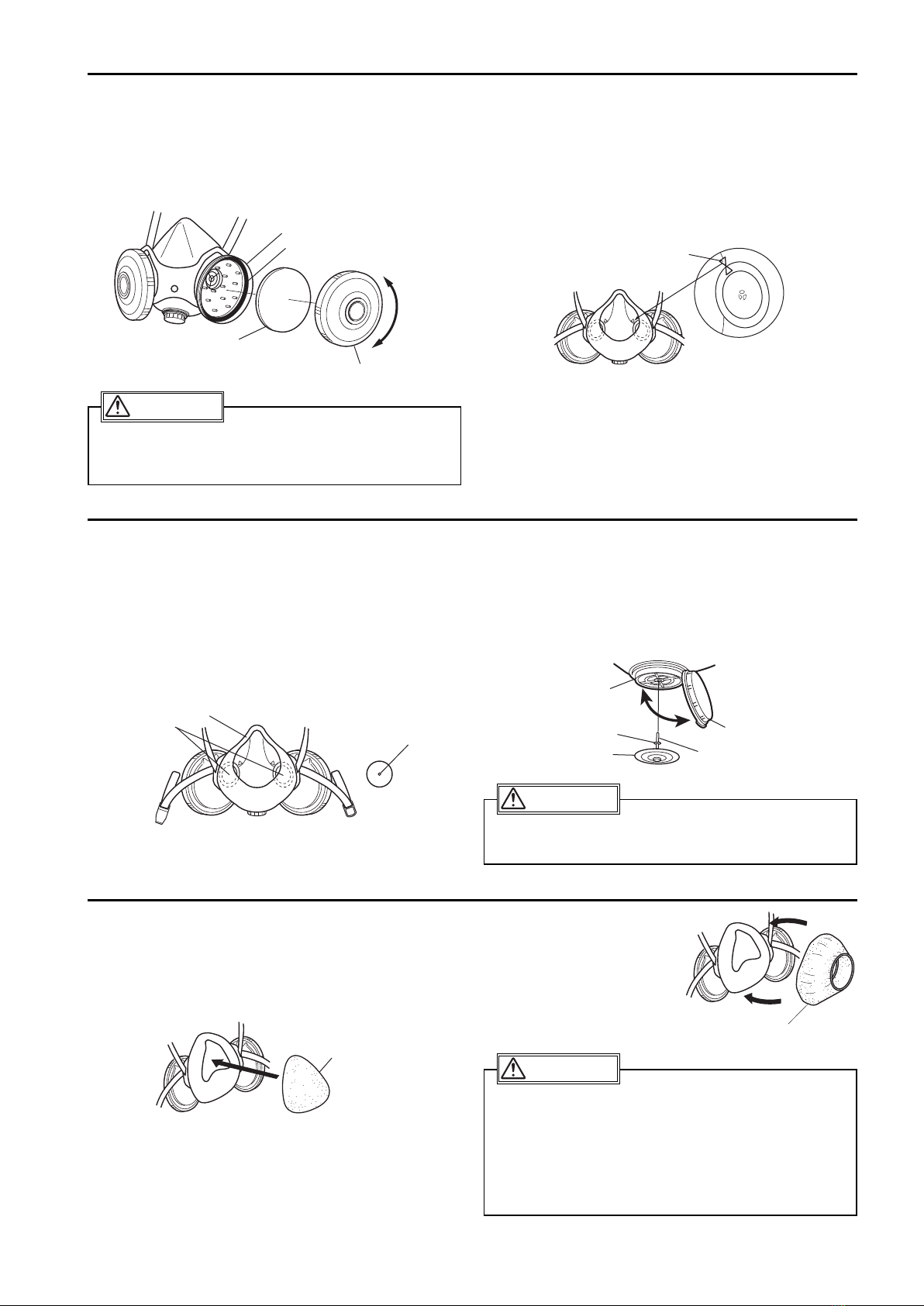

1. Cleaning after use

Perform cleaning in safe place without hazardous substance.

International Trade Division

7, Yonbancho, Chiyoda-ku, Tokyo, 102-8459, Japan

Tel :+81-3-5276-1925

Fax :+81-3-3265-1976

lDo NOT remodel or disassemble the parts that are not replaceable.

lDo NOT use parts that are not Koken genuine when replacing

parts.

WARNING

NEVER attempt the followings, or the filtering material could be

distorted or damaged, or the filtering performance be decreased.

lDo NOT apply unnecessary impact on the filtering material to get

rid of captured particulates, for example.

lDo NOT use compressed air to blow away captured particulates

attached on the filtering material. Do NOT use a vacuum cleaner

to suck captured particulates attached on the filtering material.

lDo NOT wash the filtering material in water.

WARNING

lMake sure to remove the filtering material before cleaning

respirator.

CAUTION

lAlways keep the face-contacting area clean.

Dirt attached on the face-contacting area could cause rough skin and

skin irritation.

lIf alcohol for disinfection is used, dry the respirator completely

or wipe water completely after rinsing it with water.

lDo NOT use organic solvents, such as thinner, for maintenance.

CAUTION

Check points Criteria Troubleshooting

Facepiece

No damages such as crack, distortion,

and hole, no sticky surface due to

rubber deterioration and/or no

remarkable dirt are found.

Replace the respirator

with a new one.

Clean the respirator if

remarkable dirt and/or

foreign object attached

are found.

Strap slit

Filter case

No damages such as crack, distortion,

and hole, and no remarkable dirt are

found. Filtering material can be firmly

installed.

Exhalation valve

Inhalation valve

Filter gasket

No damages such as crack, distortion,

scar, and hole and no sticky surface

due to rubber deterioration are found.

There is no adherence of remarkable

dirt and/or foreign objects.

Replace the exhalation

valve, inhalation valve

and/or filter gasket with

a new one. Clean the

parts if remarkable dirt

and/or foreign object

attached are found.

Filter cover

Exhalation valve

cover

Exhalation valve seat

No damages such as crack, distortion,

and scar are found. There is no

adherence of remarkable dirt and/or

foreign objects.

Replace the filter cover,

exhalation valve cover

and/or exhalation valve

seat with a new one.

Clean the parts if

remarkable dirt and/or

foreign object attached

are found.

Headband

Straps Fully elastic. It keeps necessary

strength to hold the respirator. Replace the headband

with a new one. Clean

the headband if

remarkable dirt is

found.

Buckles,

Plastic

molded

cradle

harness

No cracks and/or no distortions are

found. Buckles can be disconnected at

ease and can be securely fastened.

Filtering

material

External

appearance

No damages such as distortion and

hole, no remarkable dirt and/or no

excessive moisture are found.

Replace the filtering

material with a new

one.

Inhalation

resistance

Breathing is not difficult when donning

the respirator.

Overall conditions

after all parts are

assembled.

There are no missing parts. There are

no gaps created at connecting parts.

Filtering material is correctly installed in

the filter case.

Install missing parts.

Make sure to perform maintenance after

each use and keep the respirator clean.

lParts other than filtering material

2. Storage

lPlace for storage

After cleaning, store the respirator in a dry place without heavy

temperature fluctuations and/or high humidity. Do NOT pile up the

cleaned respirators, as the facepiece, headband, etc. could be

cracked and/or distorted. Avoid a direct sunlight for storage.

Prepare an exclusive storage place so that the storage condition

can be checked at ease.

1021R-06 1021R-07

Internal standard

Average

Internal standard

Average

Filtering efficiency

(Test particulate: DOP) 95.0% or more 98.8% 95.0% or more 98.0%

Inhalation resistance 80Pa or less 56Pa 80Pa or less 51Pa

Exhalation resistance 52Pa or less 34Pa 52Pa or less 29Pa

Increased value of

inhalation resistance -75Pa -87Pa

Increased value of

carbon dioxide

concentration / Dead

space

0.7% (280cm3)

or less

0.56% /

224cm3

0.7% (280cm3)

or less

0.56% /

224cm3

Weight 170g or less 150g 160g or less 149g

lFiltering material

lDo NOT perform maintenance on the used filtering material. Put

the used filtering material in a sealed bag so that captured

particulates would not diffuse and dispose of it in a proper way.

DANGER

lDo NOT reuse the filtering material that was already exposed to

highly toxic particulates such as arsenic, chrome, asbestos, etc.

(Dispose of the filtering material after each use).

WARNING

◎Gently wipe out attached particulates and dirt such as sweat with

dry and slightly wet cloth. Be sure not to damage the respirator.

◎Wash out remarkable dirt with mild neutral detergent diluted with

warm water. Be careful when handling especially on the exhala-

tion valve seat and the exhalation valve. Then rinse off neutral

detergent by rinsing completely.

◎Wipe out residual water after cleaning and dry it in the shade.

◎Disinfect the face-contacting area and inside of the facepiece by

wiping it with alcohol-soaked cloth. Then wipe the alcohol out

completely.

Document No. NS OM D-486 (E-001). Translation of Japanese User Instruction on Model 1021R as of July, 2013. Contents described in this User Instruction

may differ from the requirements/specifications exercised outside Japan. In such case, make sure to follow local laws and regulation.