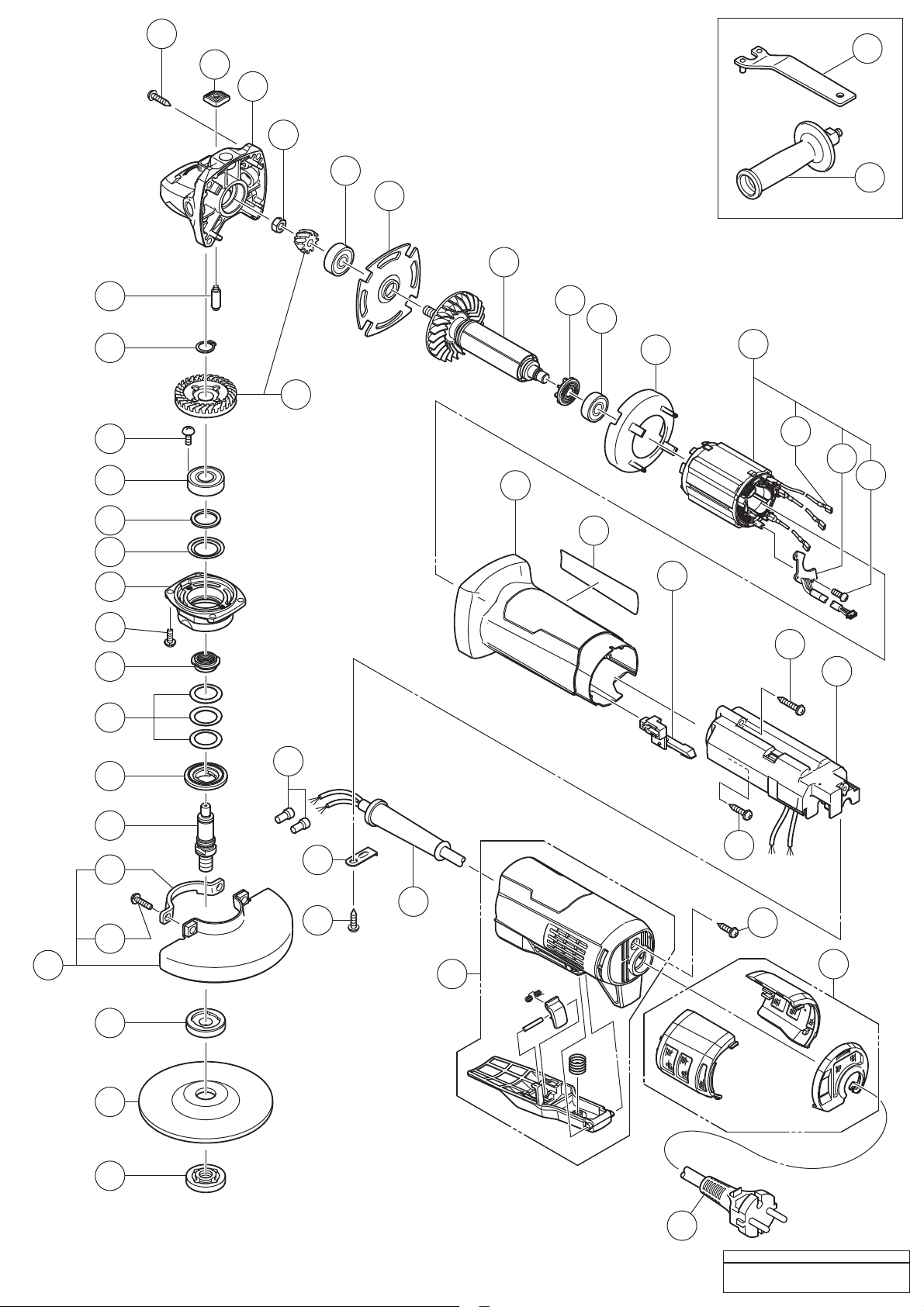

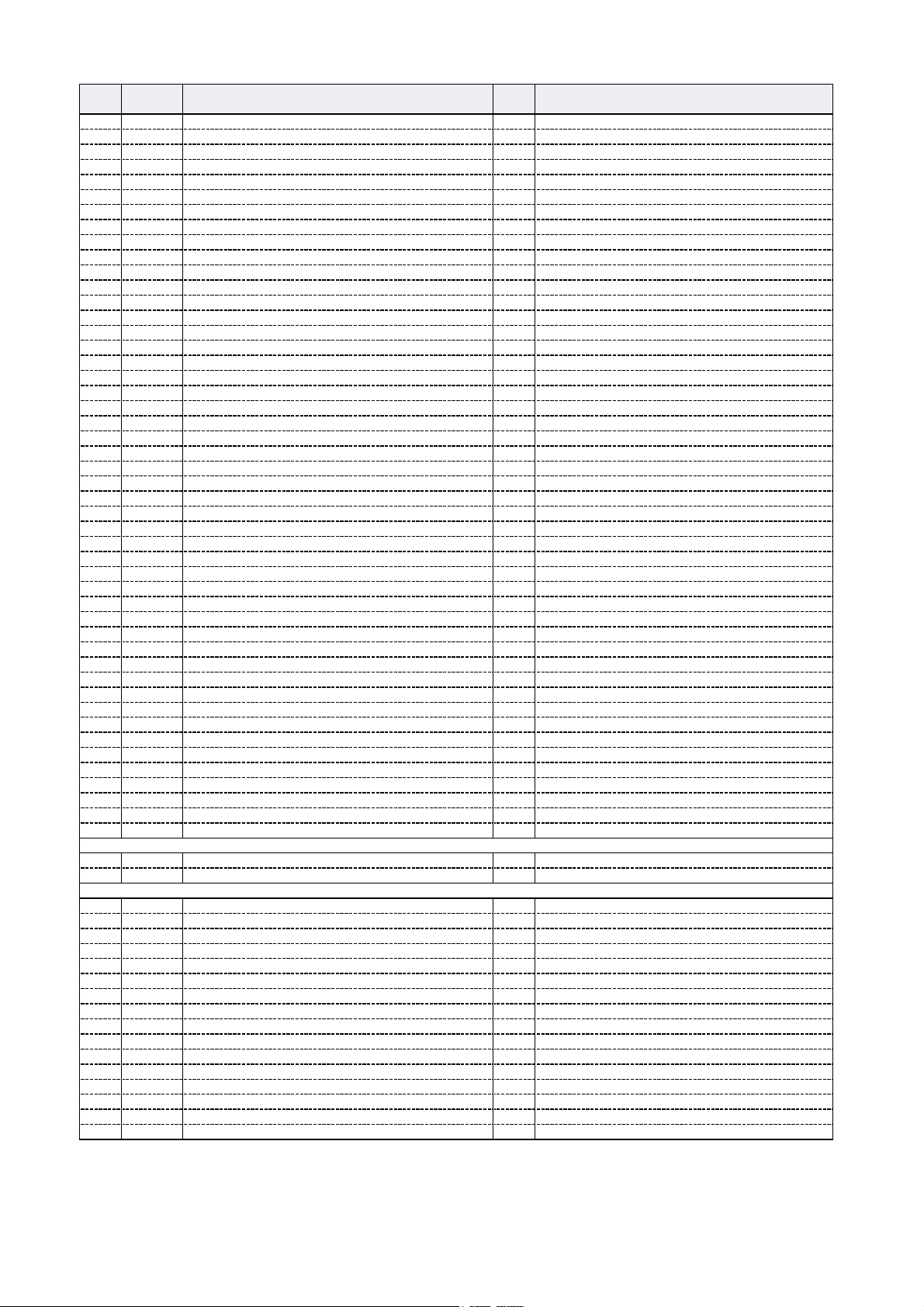

ITEM CODE NO.

NO. NO. USED

1 328643 TAPPING SCREW (W/FLANGE) D4 X 23 (BLACK) 4

2 378809 PUSHING BUTTON 1

3 378810 GEAR COVER ASS'Y 1 INCLUD. 2, 14

4 309191 SPECIAL NUT M6 1

5 378615 BALL BEARING 628DD 1

6 378812 BEARING HOLDER 1

7 361177 ROTOR 1

8 379725 DUST SEAL 1

9 608DDM BALL BEARING 608DD 1

10 378808 FAN GUIDE 1

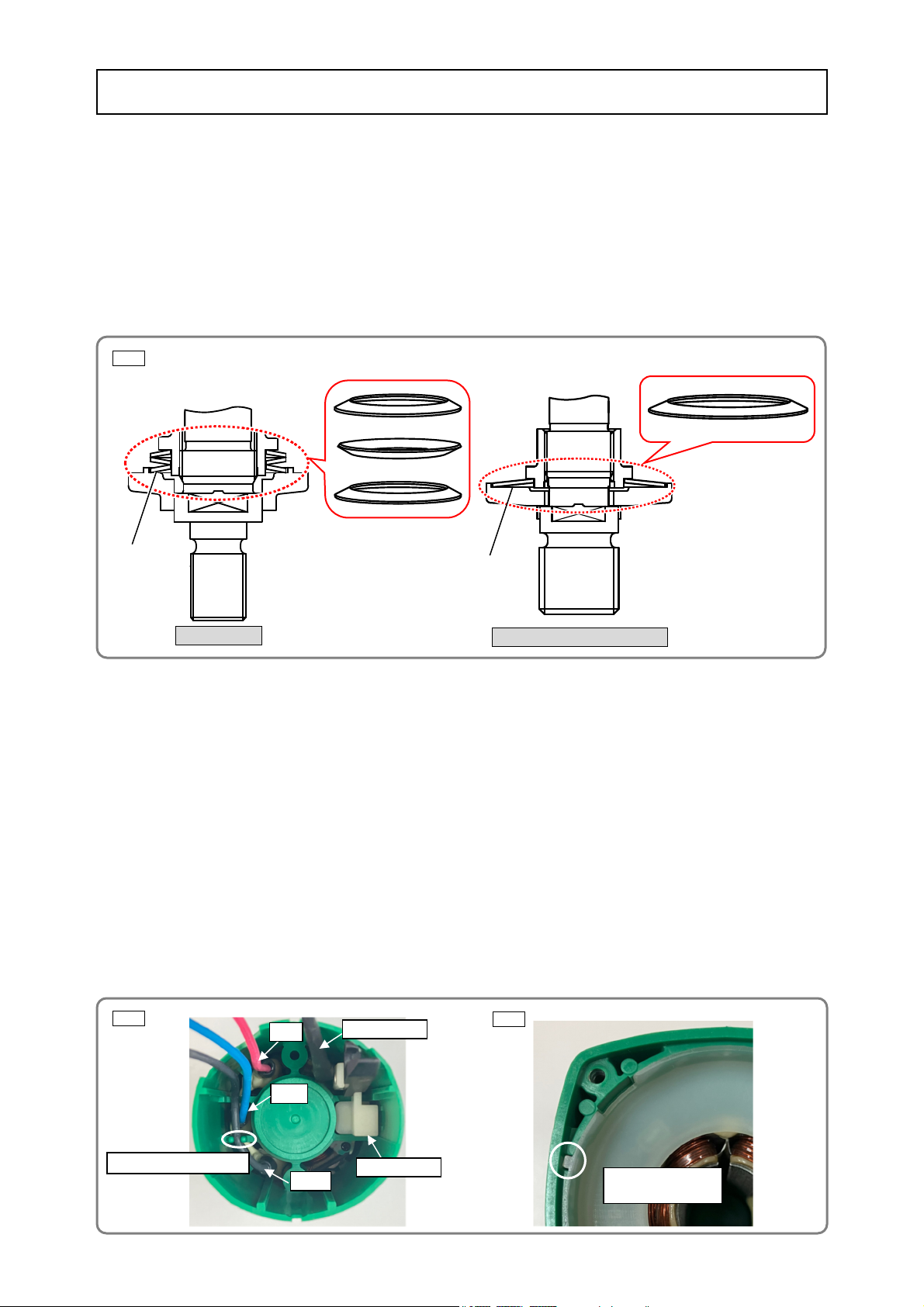

11 341130E STATOR ASS'Y (A) 220 V-240 V 1 INCLUD. 12, 13, 47

12 370131 FASTON 3

13 378813 SENSOR PCB 1

14 301943 LOCK PIN 1

15 939542 RETAINING RING FOR D12 SHAFT (10 PCS.) 1

16 371814 SLOTTED HD. SCREW (SEAL LOCK) M4 2

17 6001DD BALL BEARING 6001DDCMPS2L 1

18 376786 FELT PACKING 1

19 378823 WASHER (F) 1

20 378814 PACKING GLAND (A) 1

21 307127 SEAL LOCK SCREW (W/SP. WASHER) M4 X 12 4

22 378824 SLEEVE (F) 1

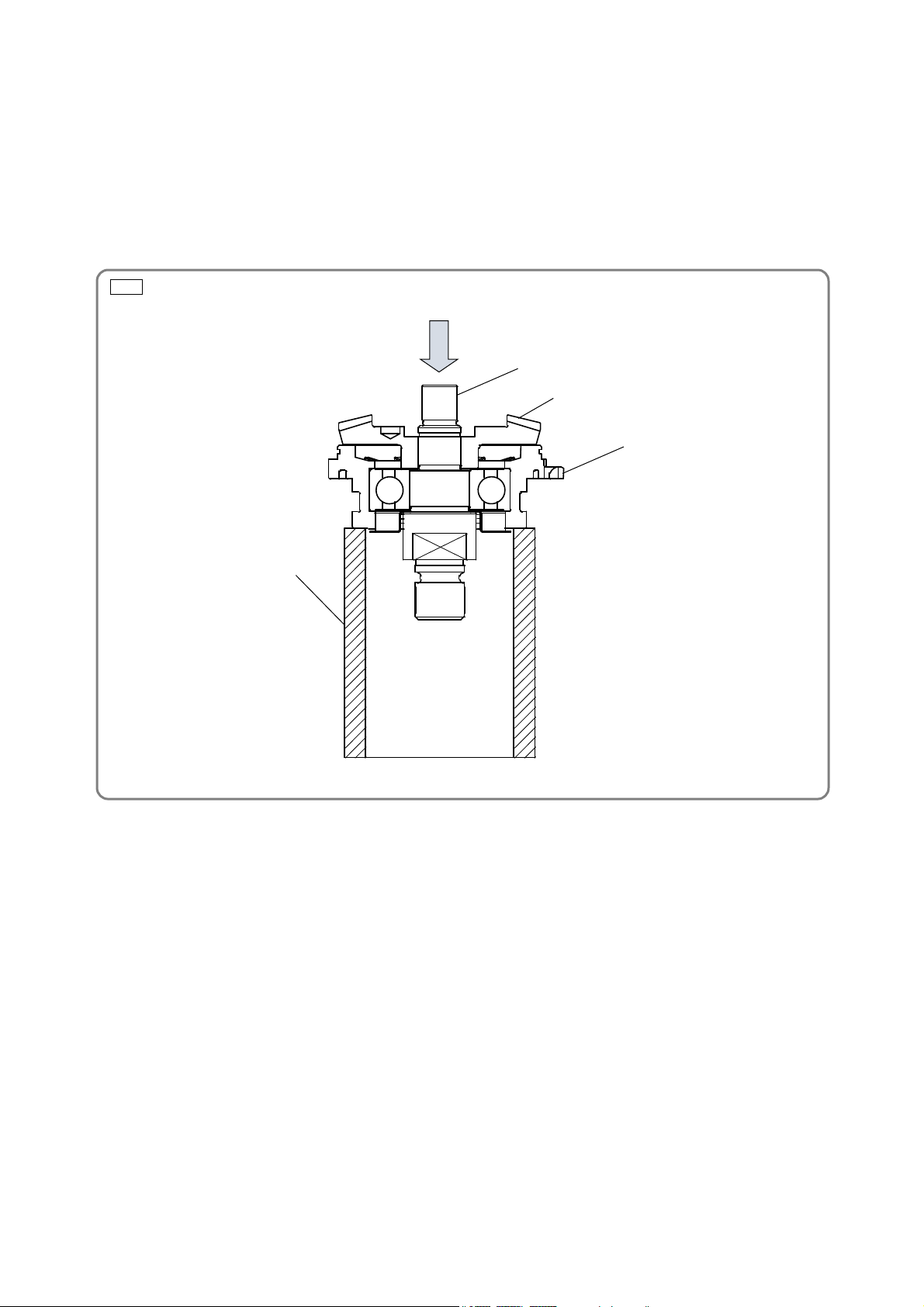

23 371667 BELLEVILLE SPRING (A) 3

24 371668 SUPPORT BODY (A) 1

25 371665 SPINDLE (A) 1

26 301949 SET PLATE 1

27 308386 MACHINE SCREW (W/SP. WASHER) M5 X 16 (BLACK) 2

28 331085 WHEEL GUARD ASS'Y 1 INCLUD. 26, 27

29 373072 WHEEL WASHER (A) 1

30 316820 D. C. WHEELS 100 MM X 4T A36Q (25 PCS.) 1

31 339578 WHEEL NUT M10 1

32 338338 GEAR AND PINION SET 1

33 378826 HOUSING 1

34 NAME PLATE 1

35 379737 SWITCH LEVER 1

36 303694 TAPPING SCREW (W/FLANGE) D4 X 35 (BLACK) 1

37 379729 CONTROLLER (B) 220 V-240 V 1

38 301653 TAPPING SCREW (W/FLANGE) D4 X 20 (BLACK) 1

39 959140 CONNECTOR 50091 (10 PCS.) 2

40 338334 CORD CLIP 1

41 984750 TAPPING SCREW (W/FLANGE) D4 X 16 1

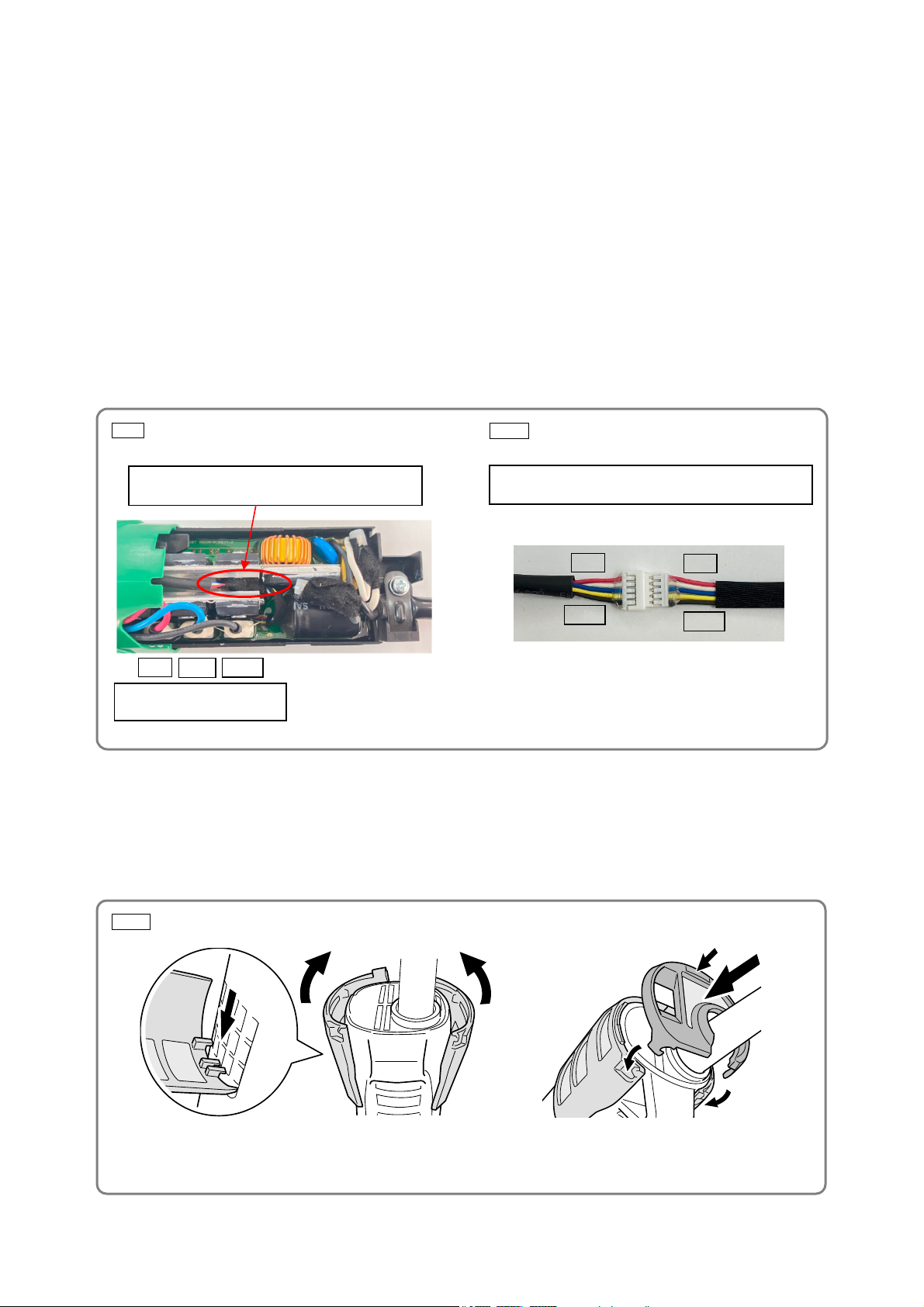

42 953327 CORD ARMOR D8.8 1

43 379732 TAIL COVER SET 1

44 307811 TAPPING SCREW (W/FLANGE) D4 X 16 (BLACK) 1

45 379204 FILTER SET 1

*46 500247Z CORD 1 (CORD ARMOR D8.8) FOR SIN (PLUG: 2 PIN)

*46 500423Z CORD 1 (CORD ARMOR D8.8) FOR SIN (PLUG: 3 PIN)

47 329623 TAPPING SCREW D2 X 8 (BLACK) 2

501 313933 WRENCH 1

502 378279 SIDE HANDLE 1

601 314051 SANDING DISCS 100 MM C-P16 (10 PCS.) 1

602 314052 SANDING DISCS 100 MM C-P20 (10 PCS.) 1

603 314053 SANDING DISCS 100 MM C-P24 (10 PCS.) 1

604 314054 SANDING DISCS 100 MM C-P30 (10 PCS.) 1

605 314055 SANDING DISCS 100 MM C-P36 (10 PCS.) 1

606 314056 SANDING DISCS 100 MM C-P40 (10 PCS.) 1

607 314057 SANDING DISCS 100 MM C-P50 (10 PCS.) 1

608 314058 SANDING DISCS 100 MM C-P60 (10 PCS.) 1

609 314059 SANDING DISCS 100 MM C-P80 (10 PCS.) 1

610 314060 SANDING DISCS 100 MM C-P100 (10 PCS.) 1

611 314061 SANDING DISCS 100 MM C-P120 (10 PCS.) 1

612 935513 WASHER NUT M10 X P1.5 1

613 936548 WASHER 1

614 936558Z RUBBER PAD 1

615 302098 GUIDE BASE 1

616 323918 DUST COLLECTION ADAPTER (DISC GRINDER) 1

DESCRIPTION REMARKS

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES