-1-

WARNING: Before attempting disassembly, be sure to turn off the power switch and disconnect the

power cord plug from the outlet.

1. Precautions on disassembly and reassembly

[Bold] numbers in the description below correspond to the item numbers in the parts list and exploded

assembly diagram for the Models G 12SE3 and G 12SE3(S), and <Bold> numbers to those for the Models

G 13SE3 and G 13SE3(S).

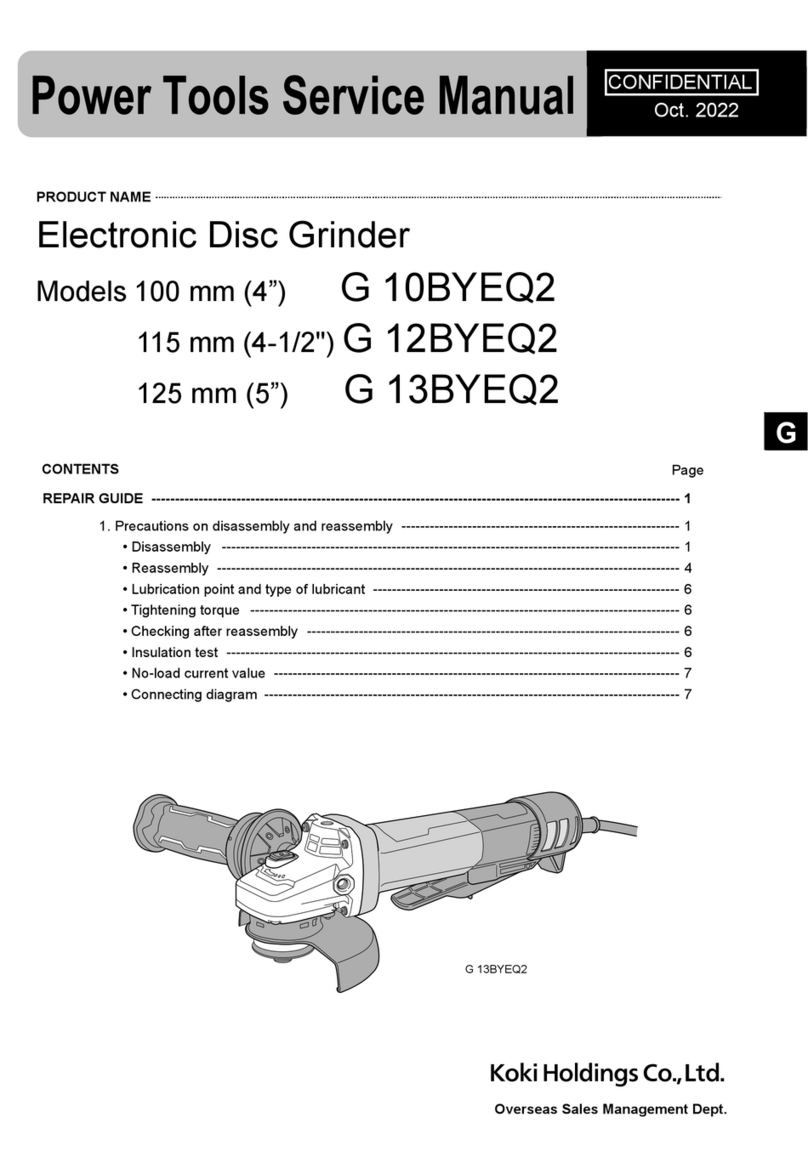

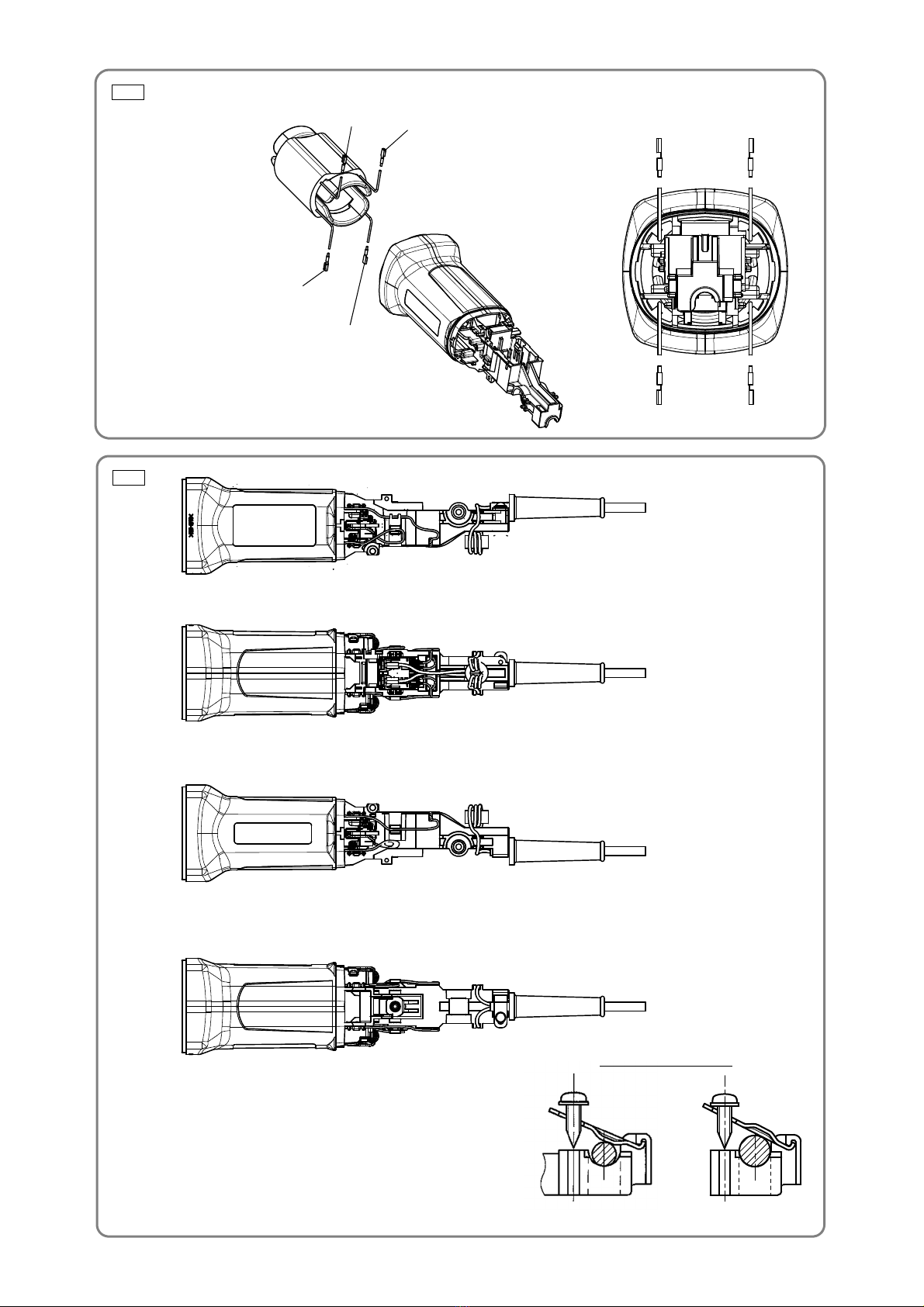

1. Removal of the armature and stator

(1) Loosen the two Tapping Screws (W/Flange) D4 x 35 [34]<34> and Tapping Screw (W/Flange) D4 x 20

[35]<35>, then pull out Tail Cover (B) [44]<44> and Tail Cover (A) [47]<47>. Remove the Carbon

Brushes (1 Pair) [40]<40>[48]<48> from the Brush Holders [42]<42>.

(2) Loosen the four Seal Lock Screws (W/Sp. Washer) M4 x 14 [7]<7> and remove the Packing Gland

[6]<6> and Lever Holder [8]<8>.

(3) Loosen the four Tapping Screws (W/Flange) D4 x 25 [1]<1> that fix the Gear Cover [2]<2> to remove

the Armature [24]<24> from the Housing [36]<36> together with the Diffuser [23]<23>. At this time,

check that the Rubber Bushing [33]<33> is fitted in the housing ball bearing chamber.

(4) Carefully wrap the Armature [24]<24> with a soft, clean rag to protect it from being damaged, and clamp

it securely in a vise. Then remove the Special Nut M7 [18]<18> and extract the Gear and Pinion Set

[25]<25>.

(5) Disconnect the four internal wires of the Stator [30]<30> from the Pushing Button Switch [43]<43> and

Brush Holders [42]<42>.

(6) Remove the Fan Guide [29]<29> and Stator [30]<30> from the Housing [36]<36>.

NOTE: • If the Stator [30]<30> is hard to be removed from the Housing [36]<36>, heat the Housing

[36]<36> up to about 60°C to facilitate removal. Then pull out the Rubber Bushing

[33]<33>.

• Each internal wire of the Stator [30]<30> is covered with a glass tube. Do not bend the

internal wires repeatedly and do not peel off the glass tubes when removing the Stator

[30]<30> from the Housing [36]<36>. Otherwise, the internal wires may be disconnected.

• Do not apply excessive force to the terminals of the Stator [30]<30> when removing them

from the Pushing Button Switch [43]<43> and Brush Holders [42]<42>. Otherwise, the

terminals of the Stator [30]<30> may be broken.

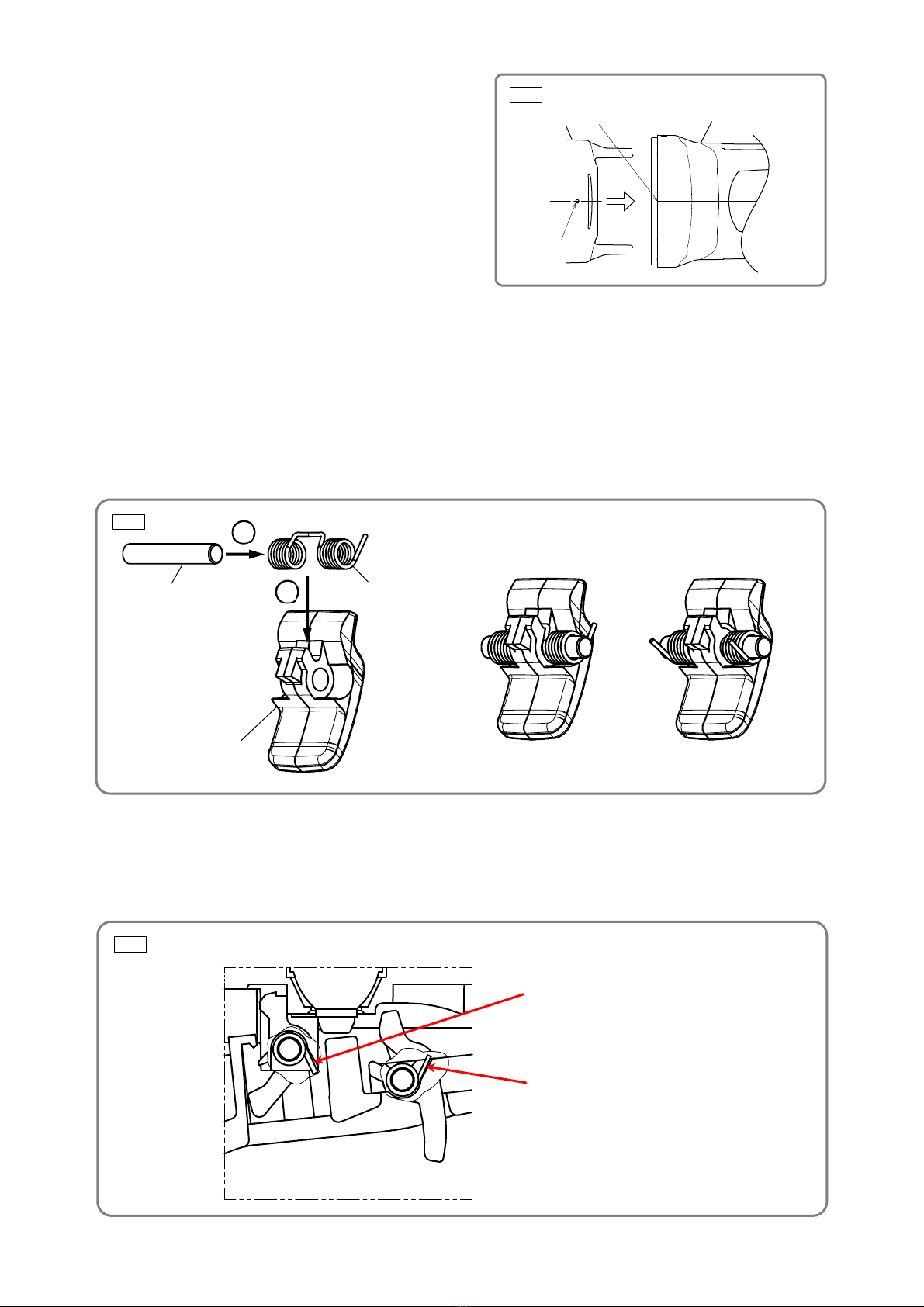

2. Removal of the rubber bushing

Insert the special repair tool J-201 spring hook (Code No. 970977) between the Rubber Bushing [33]<33>

assembled in the Housing [36]<36> and the housing ball bearing chamber, and then pull out the Rubber

Bushing [33]<33>.

3. Removal of the dust seal

(1) Insert the hooks of the J-204 bearing puller between the Ball Bearing 698SS [32]<32> and the Dust Seal

[31]<31> and fix the hooks with the wing bolts.

NOTE: Be careful not to insert the hooks excessively.

(2) Put the bearing puller on an appropriate stand. Press down on the armature shaft with a hand press and

pull out the Ball Bearing 698SS [32]<32>.

(3) Pull out the Dust Seal [31]<31> from the armature shaft.

Disassembly

REPAIR GUIDE