TABLE OF CONTENTS

1 INTRODUCTION................................................................................................................................... 3

1.1 About this manual......................................................................................................................... 3

1.2 About the upgrade kit usage......................................................................................................... 3

1.3 Waste treatment and recycling of removed material...................................................................... 3

2SAFETY................................................................................................................................................. 4

2.1 Before starting to work at the site.................................................................................................. 4

2.2 Main switch and emergency stop buttons...................................................................................... 4

2.3 After working at the site................................................................................................................. 4

3DESCRIPTION OF THE UPGRADE KIT............................................................................................... 5

3.1 Parts included in the kit................................................................................................................. 5

3.2 Required tools............................................................................................................................... 6

3.3 Terminal connections.................................................................................................................... 7

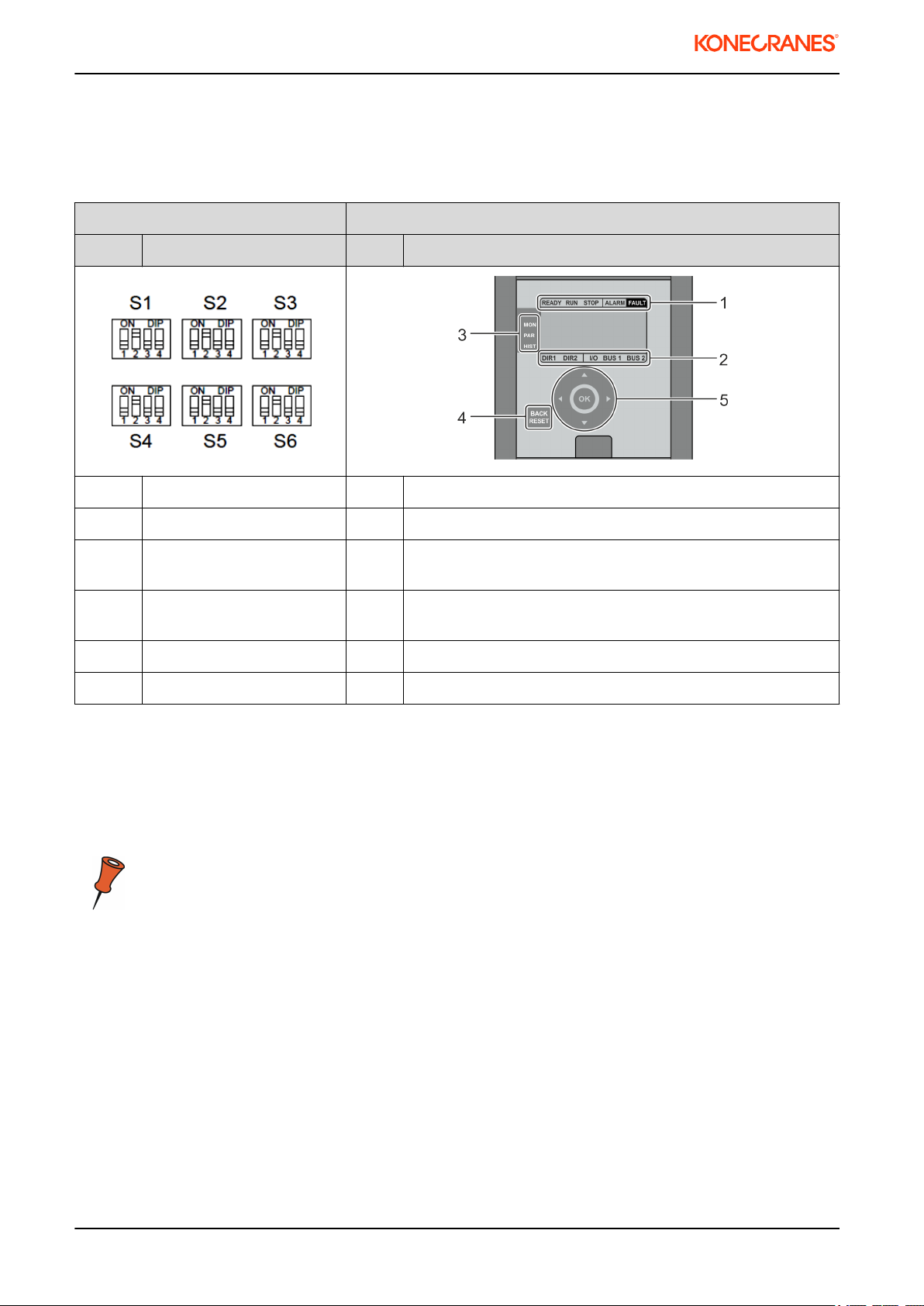

3.4 User interface................................................................................................................................ 8

3.5 EMC filter...................................................................................................................................... 8

4INSTALLATION..................................................................................................................................... 10

4.1 Preparations.................................................................................................................................. 10

4.2 Old frequency converter removal.................................................................................................. 10

4.3 Control voltage front resistors....................................................................................................... 11

4.4 By-passing the control voltage front resistor.................................................................................. 11

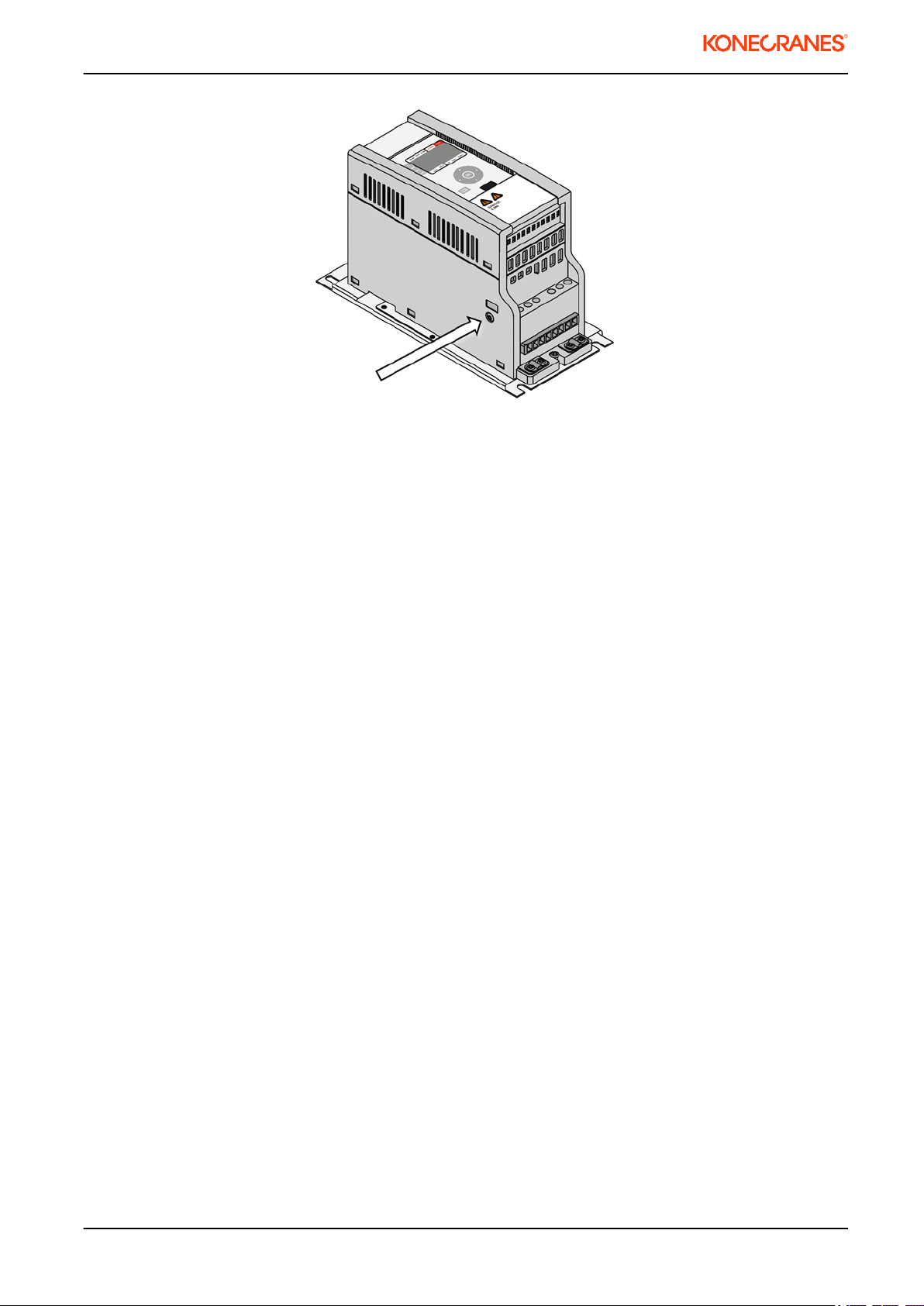

4.5 New frequency controller installation............................................................................................. 12

5 COMMISSIONING................................................................................................................................. 19

5.1 Old inverter parameter settings..................................................................................................... 19

5.2 Motor type..................................................................................................................................... 19

5.3 Traveling motor rating plate values............................................................................................... 19

5.4 Setting up the new inverter parameters......................................................................................... 19

6 TROUBLESHOOTING........................................................................................................................... 26

6.1 Purpose of troubleshooting........................................................................................................... 26

6.2 Problems and solutions................................................................................................................. 26

6.3 Fault codes and alarms................................................................................................................. 26

020145en / Revision D / 2015-04-29

2/31

This document and the information contained herein, is the exclusive property of Konecranes Plc. and represents a non-public, confidential and proprietary trade secret that may not be

reproduced, disclosed to other parties, altered or otherwise employed in any manner whatsoever without the express written consent of Konecranes Plc.

Copyright © (2014) Konecranes Plc. All rights reserved.