ViZion DR+ 1417CK Wireless Calibration Guide v1.0

Ultra UAI v4.1.0.X

Customer Support 1.800.366.5343 – HCITsupport@konicaminolta.com

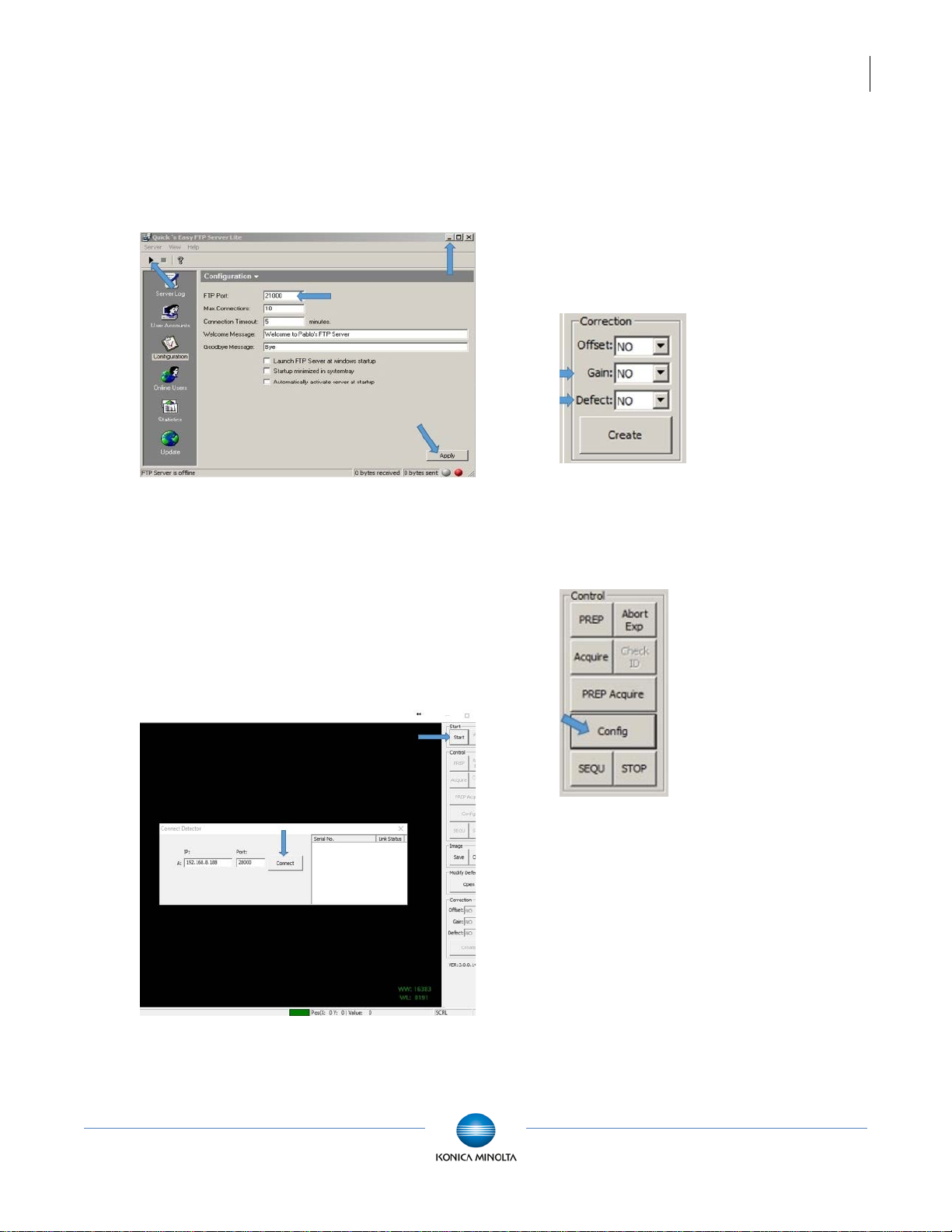

6. Click OK after you have read the

expected dose information message. A

message in red letters “Waiting for

PREP …” displays.

7. Set your kV and mAs accordingly.

8. Click PREP and make an exposure

during the “Exposure Enable” status.

Figure 24: Calibration Status

While waiting on the image to transfer,

the status changes from “Image

Getting”, indicating that the panel has

triggered an image, to “Exposure

prohibit (post offset)”, to “Exposure

enable (post offset)”.

9. After image transfer completes and the

status “Got Image” is displayed, review

the last line and look for the Center

value, verifying that the value is within

±100 of the expected gray value for that

frame #.

If the value is more than 100 below or

more than 100 above the expected gray

value, adjust your mAs up or down.

NOTE: If the Center value returned is

too low or too high, the counter may still

advance to the next number and a pop-

up for the next frame may display.

Be sure to click OK and select the

dropdown next to “Current” and reset

the Current frame # back to the previous

# that needs to be reacquired.

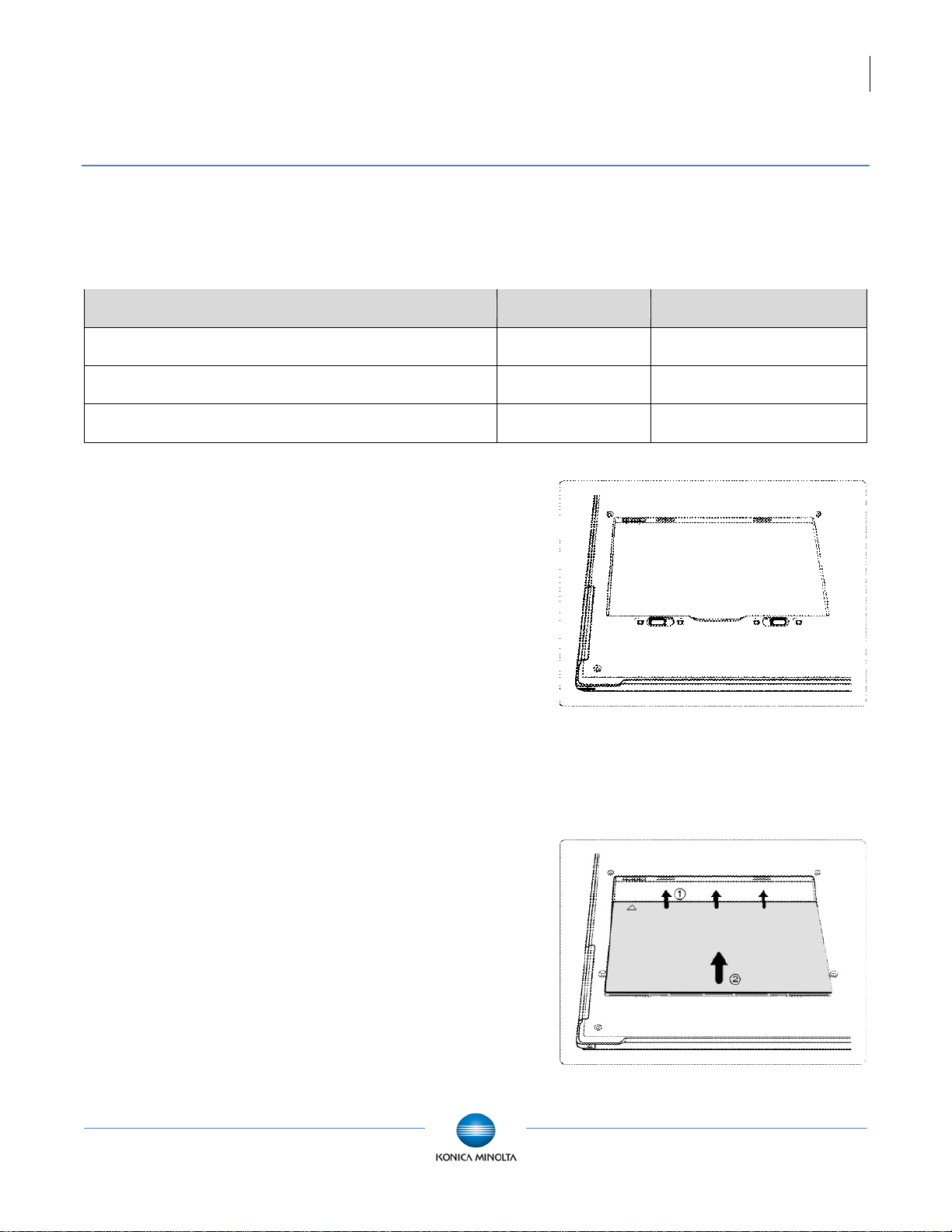

Example: In the following example

(Figure 25), the returned center value

for “Current 1” is 700, which is too low

because it is not within ±100 of the

expected center value 1000.

Also notice that the counter increased to

the next frame #. Therefore, before

acquiring the next frame, go back to

frame 1, and re-acquire frame 1, after

increasing mAs.

•Click OK and select dropdown

next to Current and select “1”.

•Then repeat steps 5-9 until the

returned value is within ± 100 of

the expected gray value.

Figure 25: Returned Expected Grey Value