3 ) DPF

DPF regeneration is used to clear PM (Particulate Matter) from the DPF filter

through continuous combustion oxidation mode (such as high temperature

heating combustion, fuel additive or catalyst reduce PM ignition combustion) to

stabilize the performance.

DPF regeneration may be performed in the following cases:

a)

The exhaust back pressure sensor is replaced.

b)

The PM trap is removed or replaced.

c)

The fuel additive nozzle is removed or replaced.

d)

The catalytic oxidizer is removed or replaced.

e)

The DPF regeneration MIL is on and maintenance is performed.

f)

The DPF regeneration control module is replaced.

4 ) BAT Match

This function enables you to perform a resetting operation on the monitoring unit

of vehicle battery, in which the original low battery fault information will be

cleared and battery matching will be done.

Battery matching must be performed in the following cases:

a)The main battery is replaced. Battery matching must be performed to clear

original low battery information and prevent the related control module from

detecting false information. If the related control module detects false

information, it will invalidate some electric auxiliary functions, such as automatic

start & stop function, sunroof without one-key trigger function, power window

without automatic function. b)Battery monitoring sensor. Battery matching is

performed to re-match the control module and motoring sensor to detect battery

power usage more accurately, which can avoid an error message displaying on

the instrument panel.

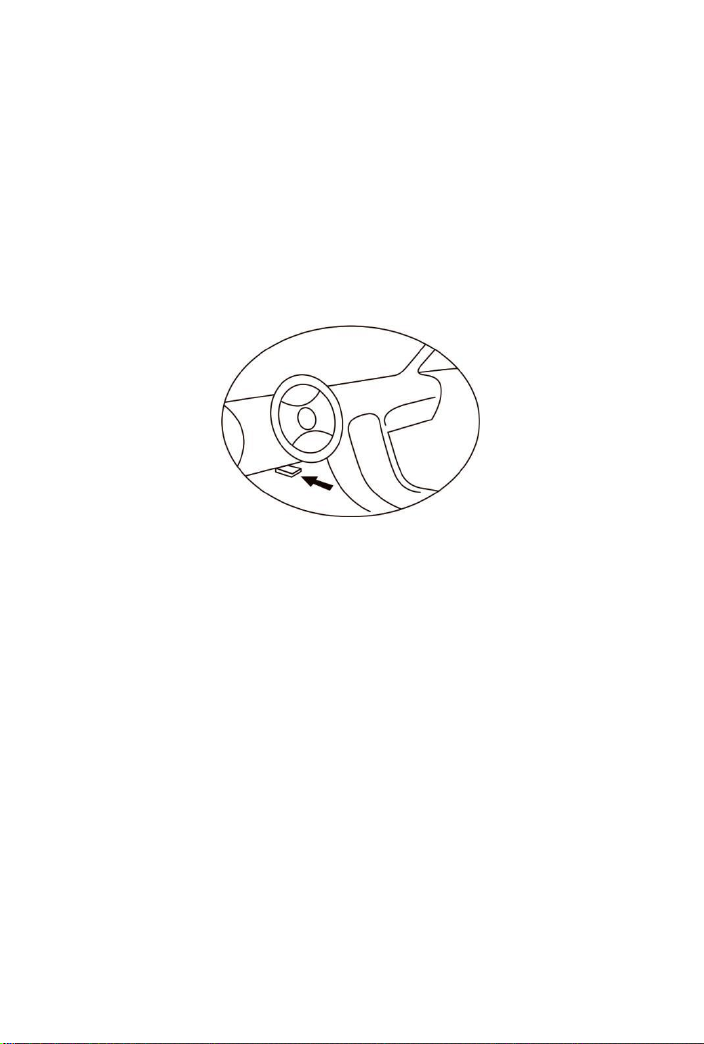

5 ) SAS

To reset the steering angle, firstly find the relative zero point position for the car

to drive in straight line. Taking this position as reference, the Ecu can calculate

the accurate angle for left and right steering.

After replacing the steering angle position sensor, replacing steering mechanical

parts(such as steering gearbox, steering column, end tie rod,steering

knuckle),performing four-wheel alignment, or recovering car body, you must

reset the steering angle;

6 ) Injector Coding

Functions performed after replacing the fuel injector;

generating a new code for a reconditioned injector.