Xpac Installation Manual -- Version 5.1 (5/08)

2REXA

Electraulic Actuators & Drives

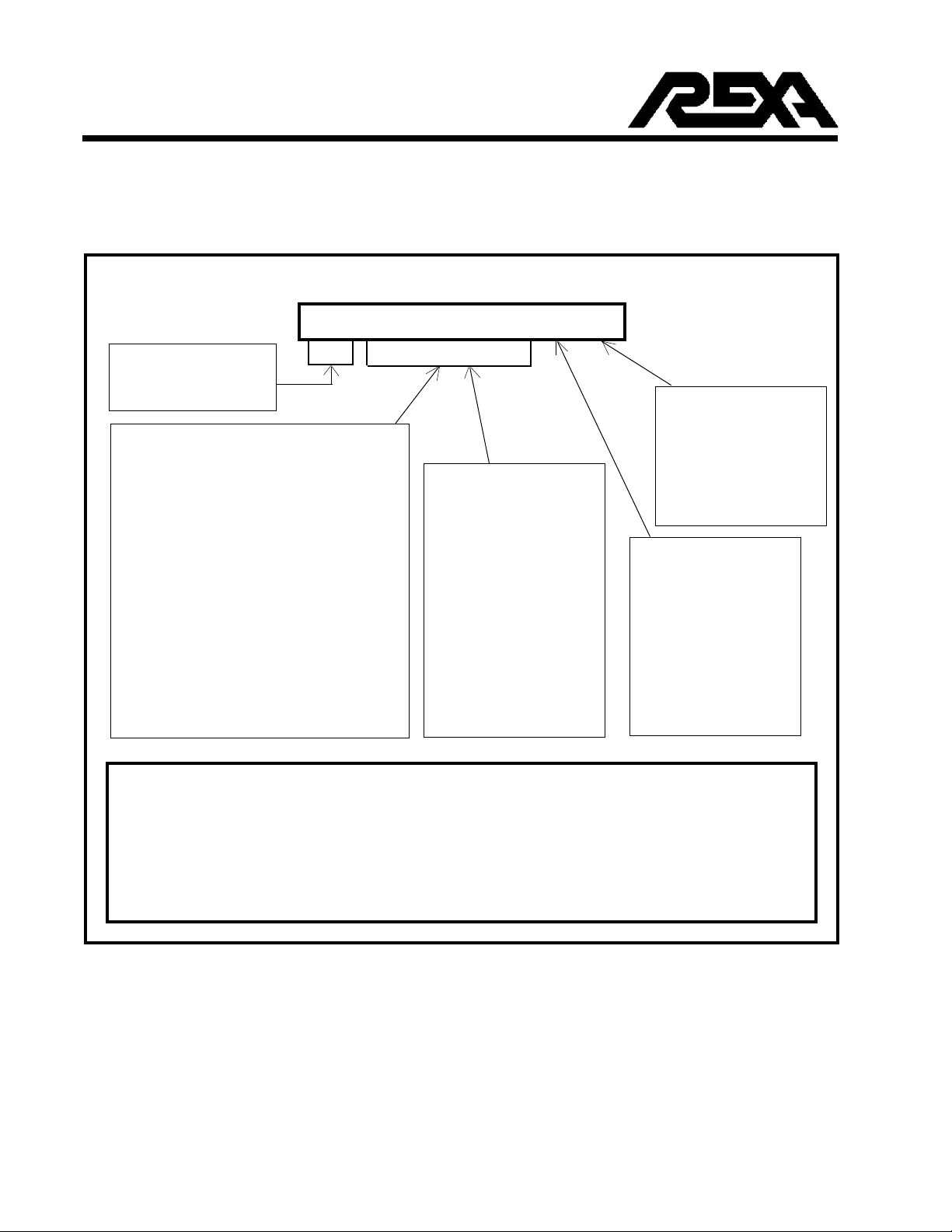

The model number provides a physical description of the mechanical portion of the actuator. The cyl-

inder size, Power Modules and failure mode are described in this simple system.

Model Number

_ _ _ _ _ – _ _ – _ – _

Spring Fail Option

(Upon Power Loss)

P: None - Lock in Place

U: Universal (Rotary)

E: Extend (Linear)

R: Retract (Linear)

A: Accumulator Failure

R Series - Xpac Rotary

L Series - Xpac Linear

D Series - Xpac Drives

Torque – Rotation

Thrust – Stroke

Series

Power Modules

B: Single B

C: Single C

½D: Single ½D

D: Single D

2D: Two D Manifold

2C: Two C Manifold

2B: Two B Manifold

P9: Booster Pump, 9

Rotary

Drive

L SERIES

Thrust Rated Strokes

(lbs) (in inches)

2,000 –.75, –2, –4 –6, –8, –11

4,000 –.75, –2, –4

5,000 –.75, –2, –4, –6, –8, –11, –16, –22

10,000 –.75, –2, –4, –6, –8, –11, –16, –22

15,000 –.75, –2, –4, –6, –8, –11, –16, –22

20,000 –.75, –2, –4, –6, –8, –11, –16, –22

30,000 –.75, –2, –4, –6, –8, –11, –16, –22

40,000 –.75, –2, –4, –6, –8, –11, –16, –22

50,000 –.75, –2, –4, –6, –8, –11, –16, –22

60,000 –.75, –2, –4, –6, –8, –11, –16, –22

80,000 –.75, –2, –4, –6, –8, –11, –16, –22

120,000 –.75, –2, –4, –6, –8, –11, –16, –22

custom

For Example: L4000-4-C-P

A linear series Xpac with 4000 lbs of thrust and C size Power Module. Lock in position

upon loss of power. Any stroke is adjustable up to 4 inches.

R2500-90-B-U

A rotary series Xpac with 2500 inch-lbs of torque and B size Power Module. Spring failure

upon loss of power. Any rotation is adjustable up to 90 degrees.

R or D SERIES

Torque Rotation

(inch-lbs) (degrees)

600 –90, –120

1,200 –90, –120

2,500 –90, –120

5,000 –90, –120

10,000 –90, –120

20,000 –90, –120

50,000 –90, –120

100,000 –90, –120

200,000 –90, –120

400,000 –90, –120

custom

Linear