Rev. Date: 1/3/12 Page3

MODEL #4200-D

General Safety

1. Read this manual carefully and become familiar with your machine. It is important to know it’s

applications, limitations, and any hazards involved prior to operating the machine.

2. This machine was designed and manufactured for blowing cellulose, fiberglass and

mineral fiber. Do not attempt to modify the unit or use it for any application it was not designed

for. If you have any questions about your intended use or the machine’s suitability, ask your

dealer/distributor or consult the factory. The manufacturers could not possibly anticipate every

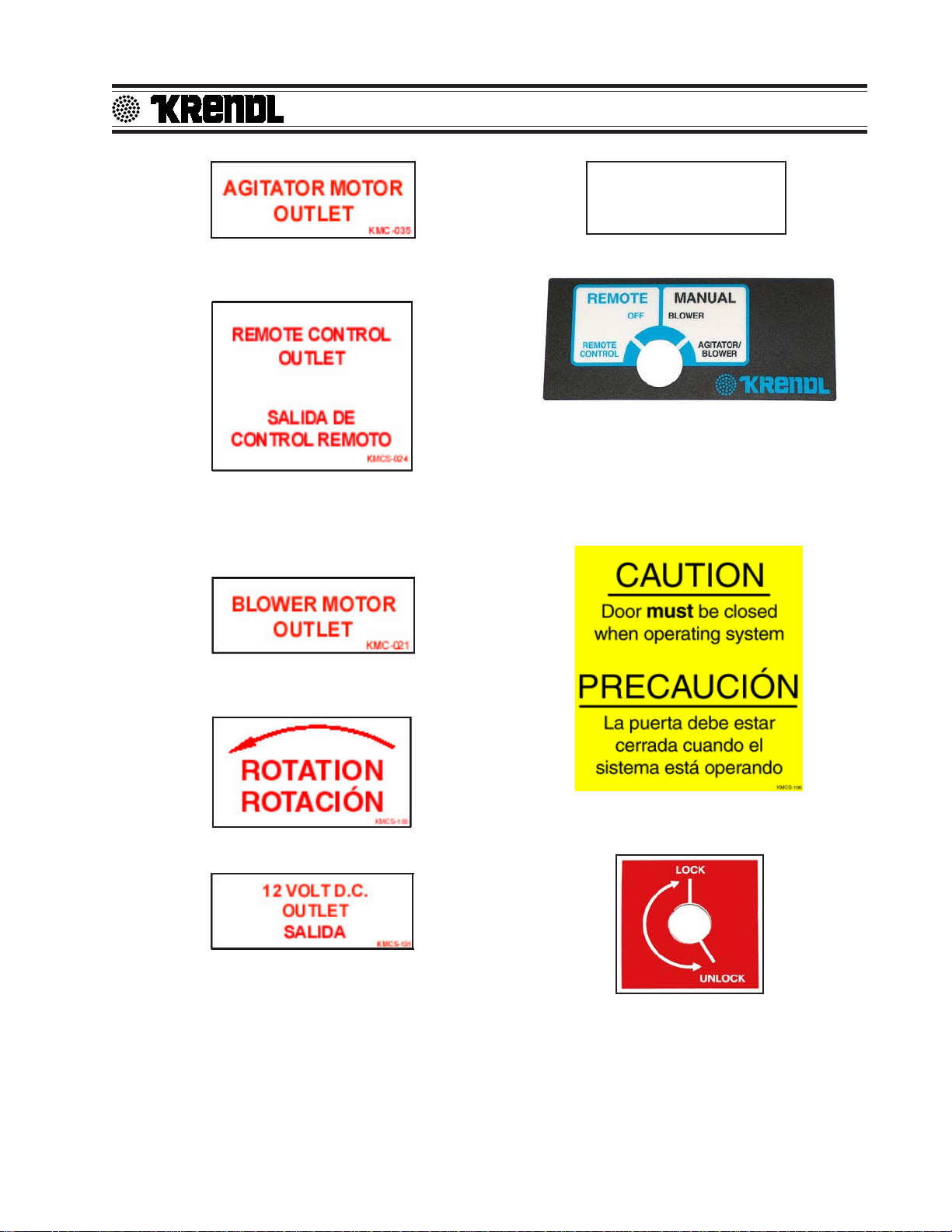

circumstance that might involve a hazard. For that reason, warnings in the manual

and warning tags or decals affixed to the unit, are not all-inclusive. If you intend to handle,

operate, or service the unit by a procedure or a method not specifically recommended by

the manufacturer, first make sure that such a procedure or method will not render this

equipment unsafe or pose a threat to you and others.

3. Do not disable any of the safety features on the equipment. These features are for your

protection and safety.

4. Read and obey all safety and operating instructions in the manual and on the machine.

5. Equipmentistobeoperated and/or maintenancedbyTRAINED &QUALIFIEDpersonnelONLY!!

6. BEFORE PERFORMING ANY MAINTENANCE ON THE MACHINE, YOU MUST FIRST:

#1 TURN MAIN DISCONNECT SWITCH ON MACHINE TO THE “OFF” POSITION

#2 TURNTHE ENGINES IGNITIONTOTHE “OFF” POSITIONAND REMOVE KEY

#3 DISCONNECT THE BATTERY CABLE

7. Do not operate the machine without all guards and safety equipment installed in the proper

location and in working order.Always follow the proper shut down procedures outlined in Item 6

when guards are removed from the machine or when compartment or electrical control doors

need to be opened.

8. If a malfunction occurs while running the machine, turn it off immediately, follow the directions

under item 6 and correct the problem prior to restarting the machine.

9. Keep body and all clothing away from rotating equipment. Rotating shafts can be dangerous.

10. Always wear proper safety equipment when operating the machine. This includes steel toed

shoes, safety glasses and a respirator.

11. Under no circumstances should your hand, a stick or a broom be used to force material down

into the hopper. The machine is a self feeding design and requires no outside assistance.

12. Stand on the floor, not a platform while operating the machine. The operator may lose balance

and fall while loading bags of material.

AllModel #4200 Machinesarefactoryequipped withside,front,and maindrivebeltguards. Thetop

of the machine is not guarded since it poses no safety threat for normal insulation blowing operations

when mounted as shown in the installation guide. The machine is designed to be mounted in the van

body of the contractor’s truck and the rear of the machine against the wall of the van body.

Always turn the main power switch (located on the electrical box) to off and unplug the remote cord

from the receptacle for any type of machine maintenance or adjustments. An additional safety feature

is the ability to adjust the material slide gate from the outside of the machine. Rotate the adjustment

handle clockwise to open the slide to the desired setting, no entrance into the machine is required.

All safety features are incorporated into the machine to protect everyone from serious

injury. Operate your machine according to the outlined instructions in the manual with all

guards in place and securely latched. Operation with any guards removed can result in injury

to or loss of fingers, hands, arms, toes, feet, legs, hair, and even your eyes.