CONTENTS

2 www.krohne.com 09/2010 - 4000049805 - QS OPTIFLEX 1300 R08 en

OPTIFLEX 1300 C

1 Safety instructions 4

2 Installation 5

2.1 Intended use ..................................................................................................................... 5

2.2 Scope of delivery............................................................................................................... 5

2.3 Visual Check ..................................................................................................................... 7

2.4 Storage ............................................................................................................................. 8

2.5 Transport .......................................................................................................................... 9

2.6 Pre-installation requirements ....................................................................................... 10

2.7 How to prepare the tank before you install the device.................................................. 10

2.7.1 Pressure and temperature ranges....................................................................................... 10

2.7.2 General information for nozzles........................................................................................... 12

2.7.3 Installation requirements for concrete roofs....................................................................... 14

2.8 Installation recommendations for liquids...................................................................... 14

2.8.1 General requirements .......................................................................................................... 14

2.8.2 How to attach probes to the bottom of the tank................................................................... 15

2.8.3 Standpipes............................................................................................................................. 15

2.9 Installation recommendations for solids....................................................................... 16

2.9.1 Nozzles on conical silos........................................................................................................ 16

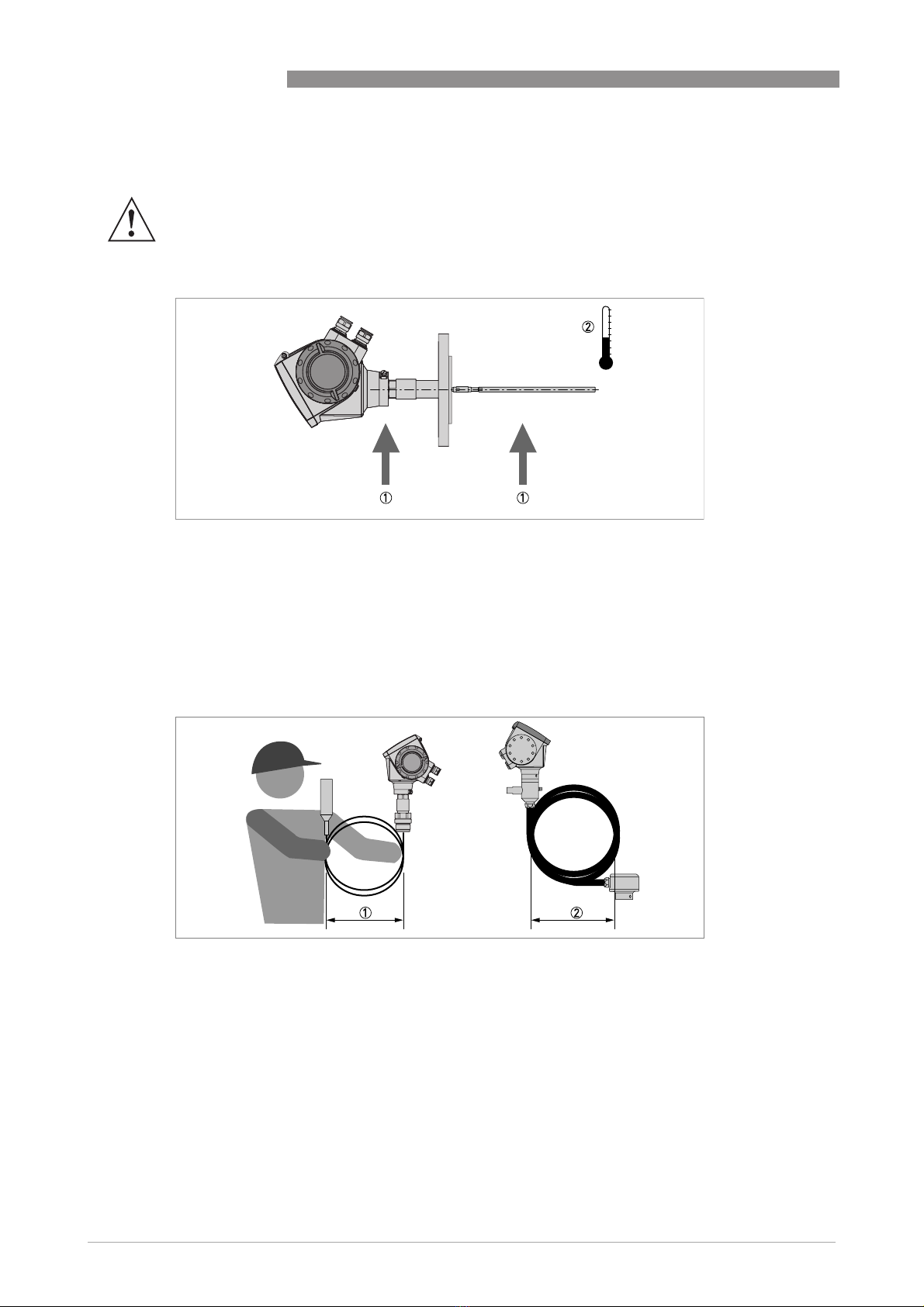

2.9.2 Traction loads on the probe.................................................................................................. 18

2.10 How to install the device on the tank ........................................................................... 18

2.10.1 How to assemble the single rod probe (single-piece probe) ............................................. 18

2.10.2 How to assemble the single rod probe (segmented probe)............................................... 18

2.10.3 How to assemble the segmented coaxial probe ................................................................ 18

2.10.4 How to install a device with a flange connection................................................................ 19

2.10.5 How to install a device with a threaded connection........................................................... 20

2.10.6 How to install a cable probe in the tank ............................................................................. 21

2.10.7 Installation recommendations for non-metallic tanks and pits ........................................ 22

2.10.8 How to assemble the remote housing................................................................................ 23

2.10.9 How to turn or remove the signal converter ...................................................................... 26

2.10.10 How to attach the weather protection to the device......................................................... 27

2.10.11 How to open the weather protection ................................................................................ 28

2.11 Electromagnetic compatibility ..................................................................................... 29

3 Electrical connections 30

3.1 Safety instructions.......................................................................................................... 30

3.2 Electrical installation: outputs 1 and 2 .......................................................................... 30

3.3 Electrical connection for current output ....................................................................... 31

3.3.1 Non-Ex................................................................................................................................... 31

3.3.2 Ex i ......................................................................................................................................... 31

3.3.3 Ex d........................................................................................................................................ 31

3.3.4 PROFIBUS PA........................................................................................................................ 32

3.3.5 FOUNDATION Fieldbus ......................................................................................................... 32

3.4 Protection category ........................................................................................................32