Foreword

3

Pos: 4 / BA/I nhaltsverz eichnis Sprac henne utral @ 1 0\mod_1 221574 899104 _0.doc @ 135495

1 Foreword .................................................................................................................................................5

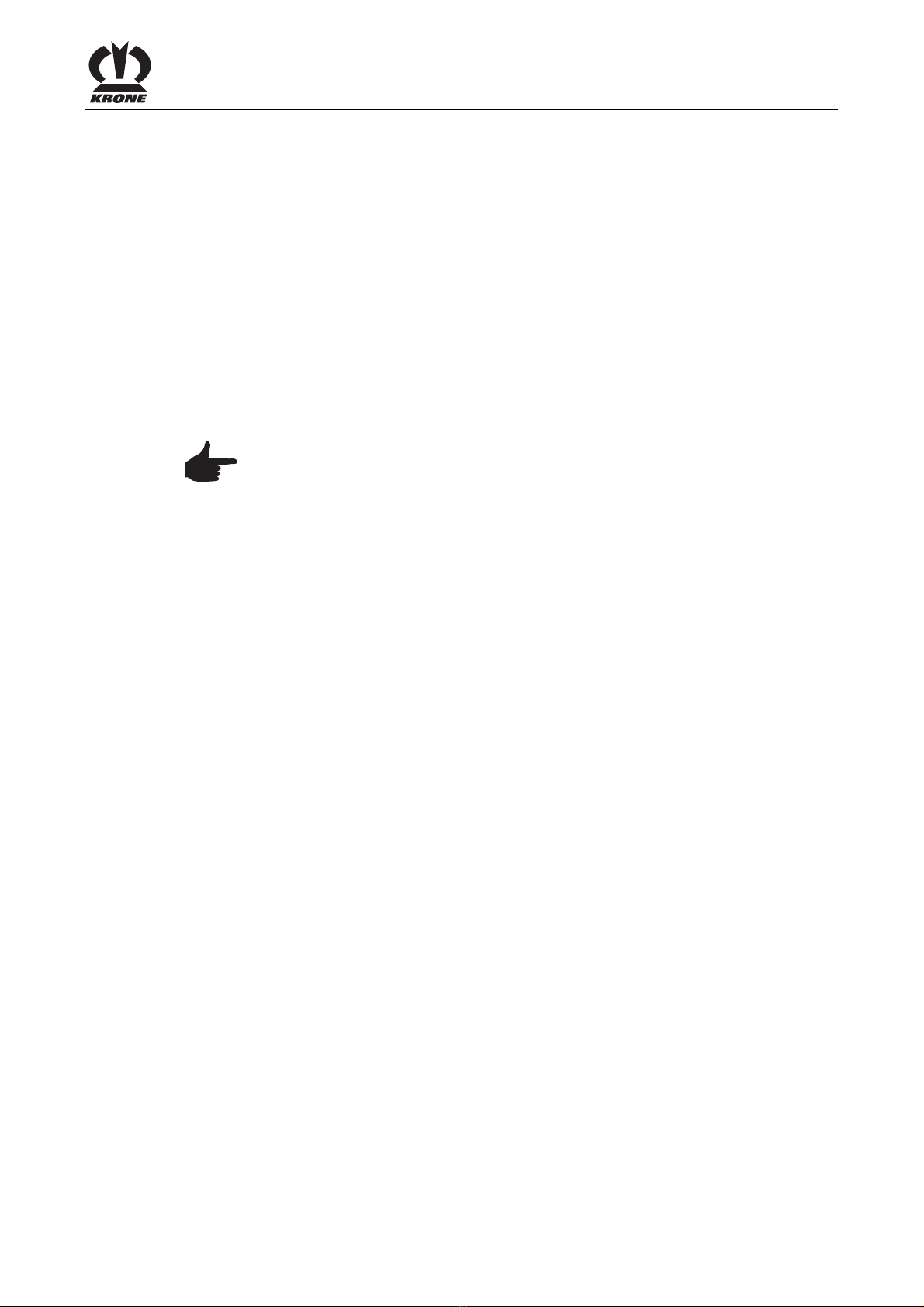

2 Introduction.............................................................................................................................................6

2.1 Purpose of Use .................................................................................................................................. 6

2.2 Validity ............................................................................................................................................... 6

2.2.1 Contact........................................................................................................................................... 6

2.3 Identification Plate ............................................................................................................................. 7

2.4 Information Required for Questions and Orders................................................................................ 7

2.5 Intended Use ..................................................................................................................................... 8

2.6 Technical data ................................................................................................................................... 8

3 Safety.......................................................................................................................................................9

3.1 Identifying Symbols in the Operating Instructions ............................................................................. 9

3.2 Identification of the hazard warnings ................................................................................................. 9

3.2.1 Personnel Qualification and Training........................................................................................... 10

3.2.2 Dangers in Case of Non-compliance with the Safety Instructions............................................... 10

3.2.3 Safety-conscious work practices ................................................................................................. 10

3.3 Safety Instructions and Accident Prevention Regulations............................................................... 11

3.4 Attached devices ............................................................................................................................. 12

3.5 PTO Operation................................................................................................................................. 13

3.6 Maintenance .................................................................................................................................... 14

3.7 Unauthorised Conversion/Modification and Spare Parts Production .............................................. 15

3.8 Inadmissible Modes of Operation .................................................................................................... 15

3.9 Introduction ...................................................................................................................................... 16

3.10 Position of the Adhesive Safety Stickers on the Machine ............................................................... 16

3.11 Position of the General Information Labels on the Machine............................................................ 18

3.11.1 Re-Ordering the Adhesive Safety and Information Labels...................................................... 19

3.11.2 Affixing the Adhesive Safety and Information Labels .............................................................. 19

4 Start-up..................................................................................................................................................20

4.1 Stop points ....................................................................................................................................... 21

4.2 Attachment to the forage harvester ................................................................................................. 21

4.2.1 Adjusting the adapter frame......................................................................................................... 22

4.2.2 Pendulum frame........................................................................................................................... 23

4.2.3 Coupling....................................................................................................................................... 24

4.2.4 Aligning the Cutting System......................................................................................................... 26

5 Driving and Transport..........................................................................................................................27

6 Operation...............................................................................................................................................28

6.1 From transport into working position ............................................................................................... 28

6.1.1 Working position .......................................................................................................................... 28

6.2 Detaching the machine .................................................................................................................... 30

7 Settings .................................................................................................................................................32

7.1 Adjusting the distance between the scraper bars and the auger conveyor..................................... 32