Table of Contents

2

Pos: 1 /Überschrif ten/Überschrift en 1/F-J/Inh altsverzeichnis @ 31\mod_125 1969952727_ 78.docx @ 30216 5 @ 1 @ 1

1 Table of Contents

Pos: 2 /BA/Inhalts verzeichnis Spr achenneutr al @ 10\mod_ 1221574899104 _0.docx @ 1354 95 @ @ 1

1Table of Contents...................................................................................................................................2

2Operation.................................................................................................................................................3

2.1 Preparing Film Tying .......................................................................................................................... 4

2.1.1 Notes on Operation ........................................................................................................................ 4

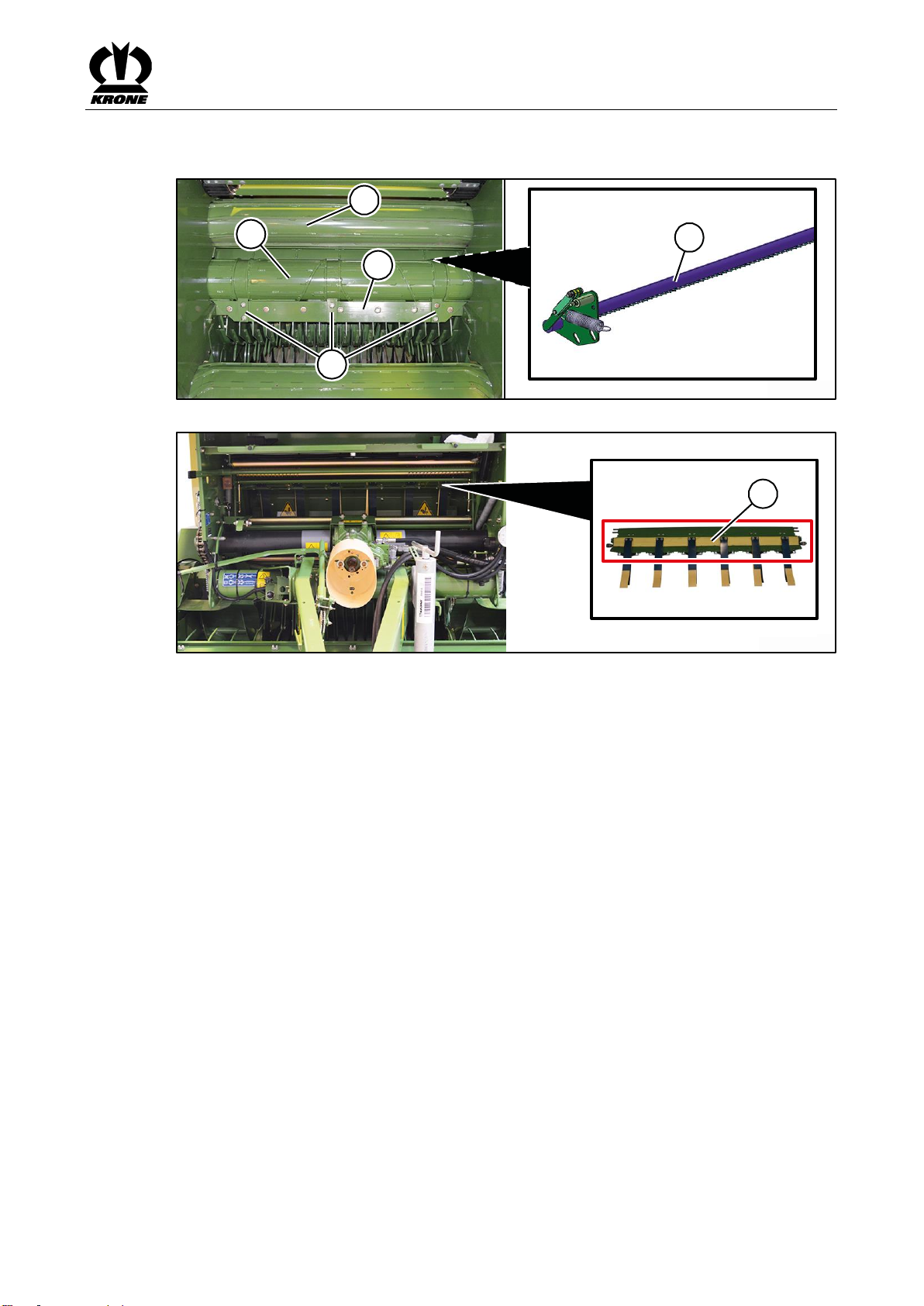

2.1.2 Removing Paint Residues and Welding Residues Before Start-up ............................................... 5

2.1.3 Inserting Film ................................................................................................................................. 6

2.1.4 Checking the Stretching of the Inserted Film ............................................................................... 10

2.2 Setting Film Tying in the Terminal ................................................................................................... 11

2.2.1 Menu 1-1 “Number of Film Layers” .............................................................................................. 11

2.2.2 Menu 1-4 “Tying Start Delay” ....................................................................................................... 12

2.2.3 Menu 1-8 “Selection Type of Tying”............................................................................................. 13

2.2.4 Menu 10 “Manual Operation” ....................................................................................................... 14

2.3 Error Messages ............................................................................................................................... 16

3Important Settings for Film Tying.......................................................................................................18

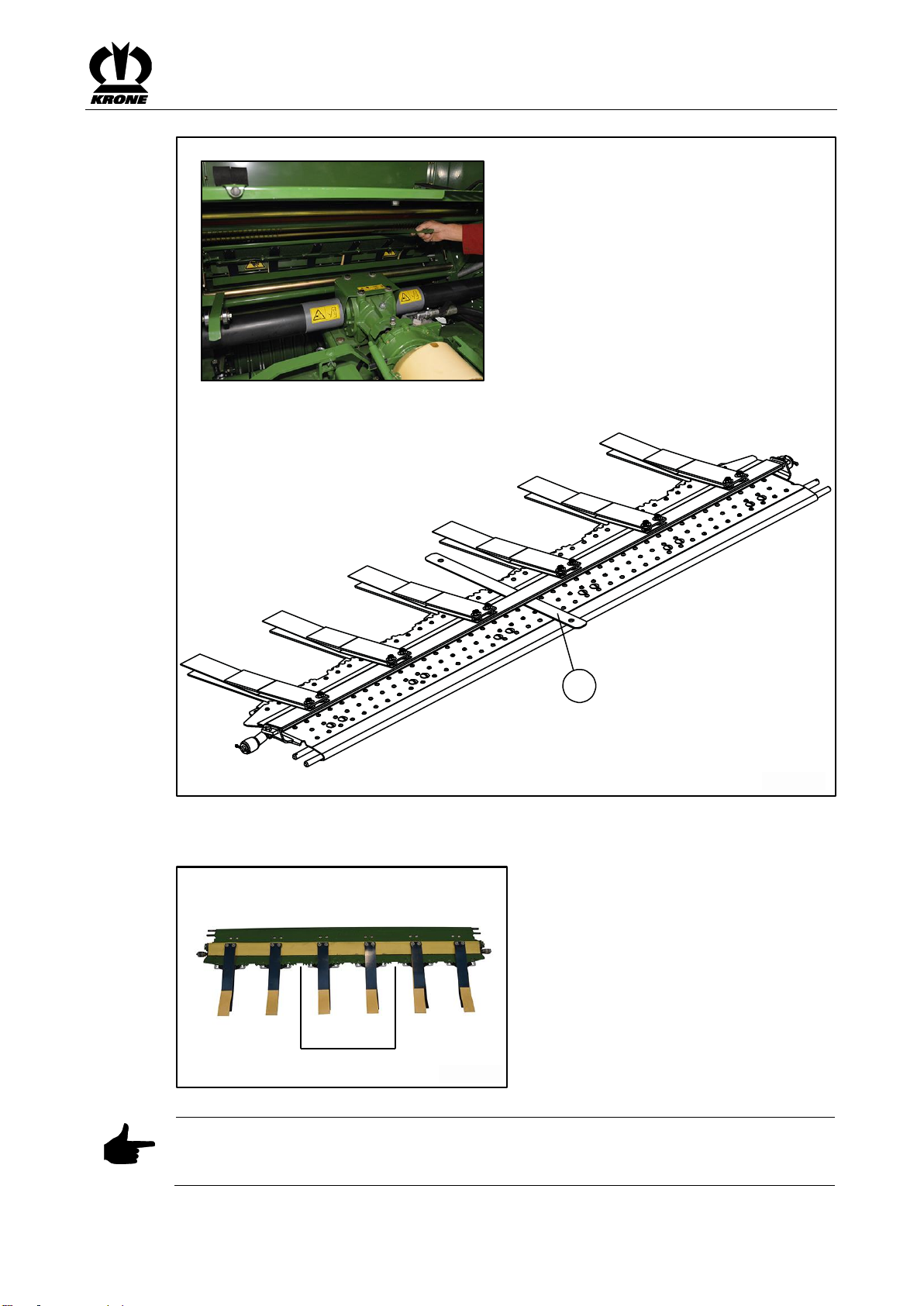

3.1 Setting the Retaining Comb for Film Tying ...................................................................................... 19

3.2 Checking the Retaining Comb for Film Tying .................................................................................. 20

3.3 Adjusting the film brake ................................................................................................................... 21

3.4 Checking and Setting Deceleration of Net Brake Discs .................................................................. 24

3.5 Setting Scraper to Spiral Roller ....................................................................................................... 25

3.6 Checking the Position of the Net Rocker Arm ................................................................................. 27

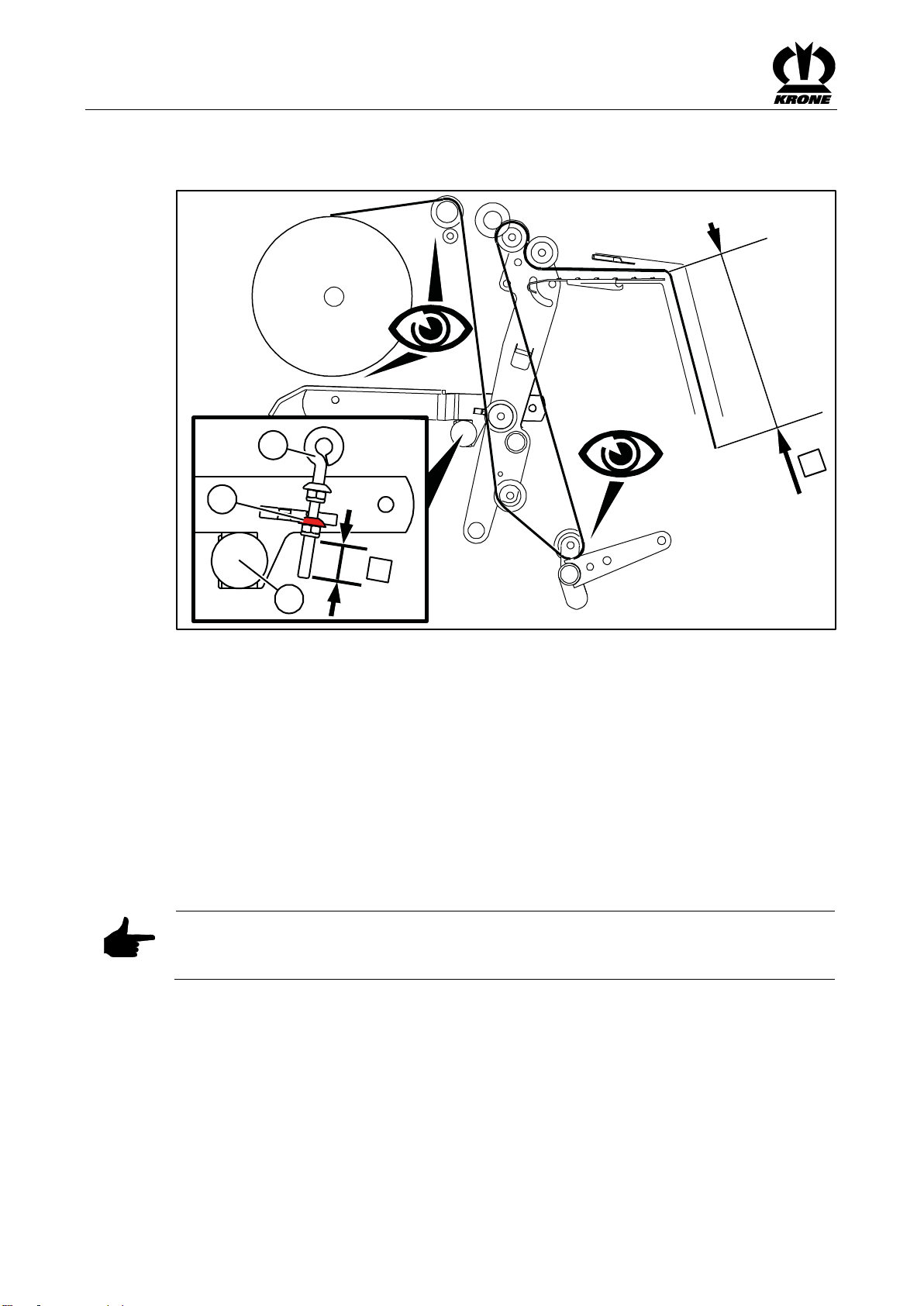

3.6.1 Checking and Setting Feed Position ........................................................................................... 27

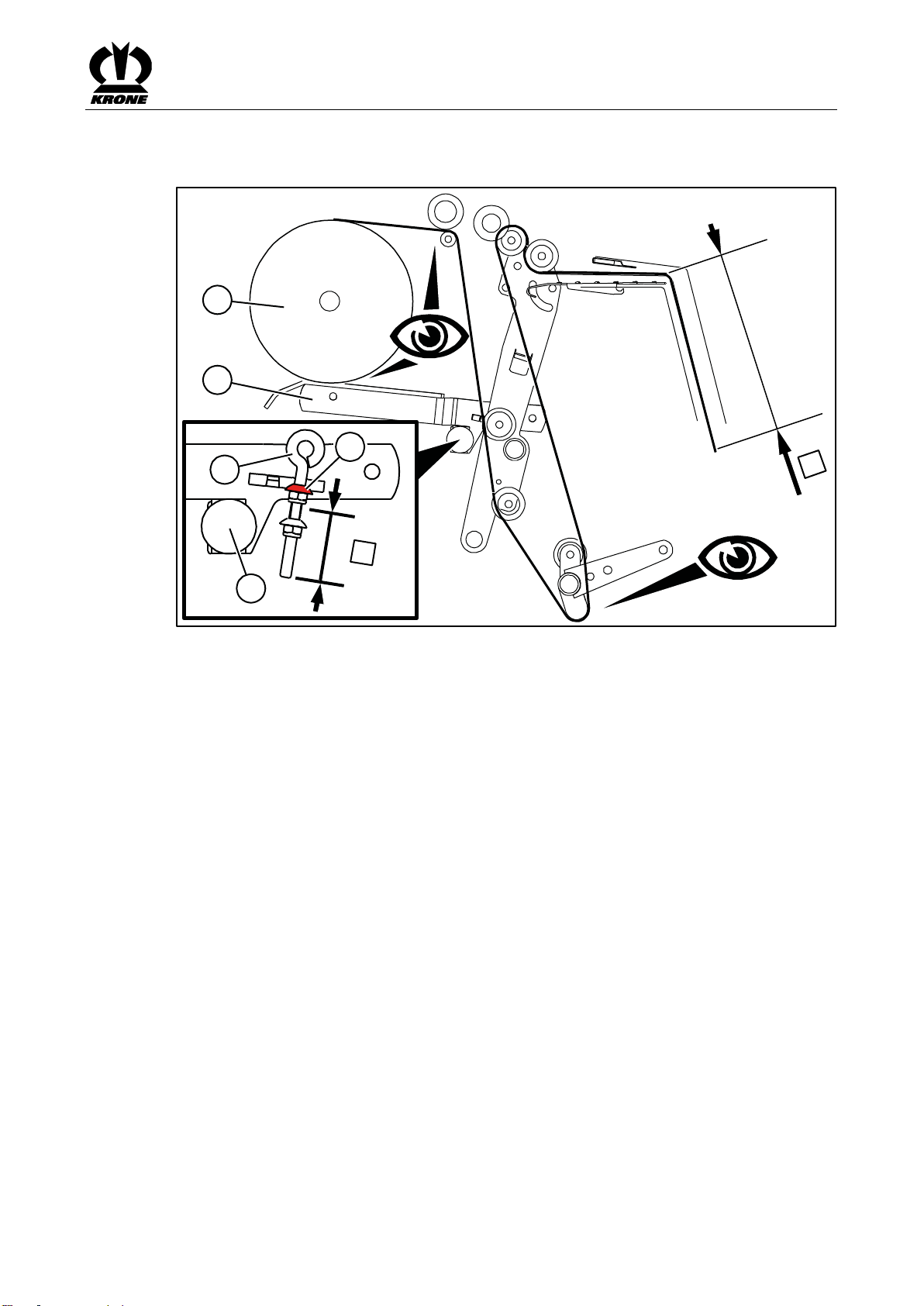

3.6.2 Checking and Setting End Position ............................................................................................. 28

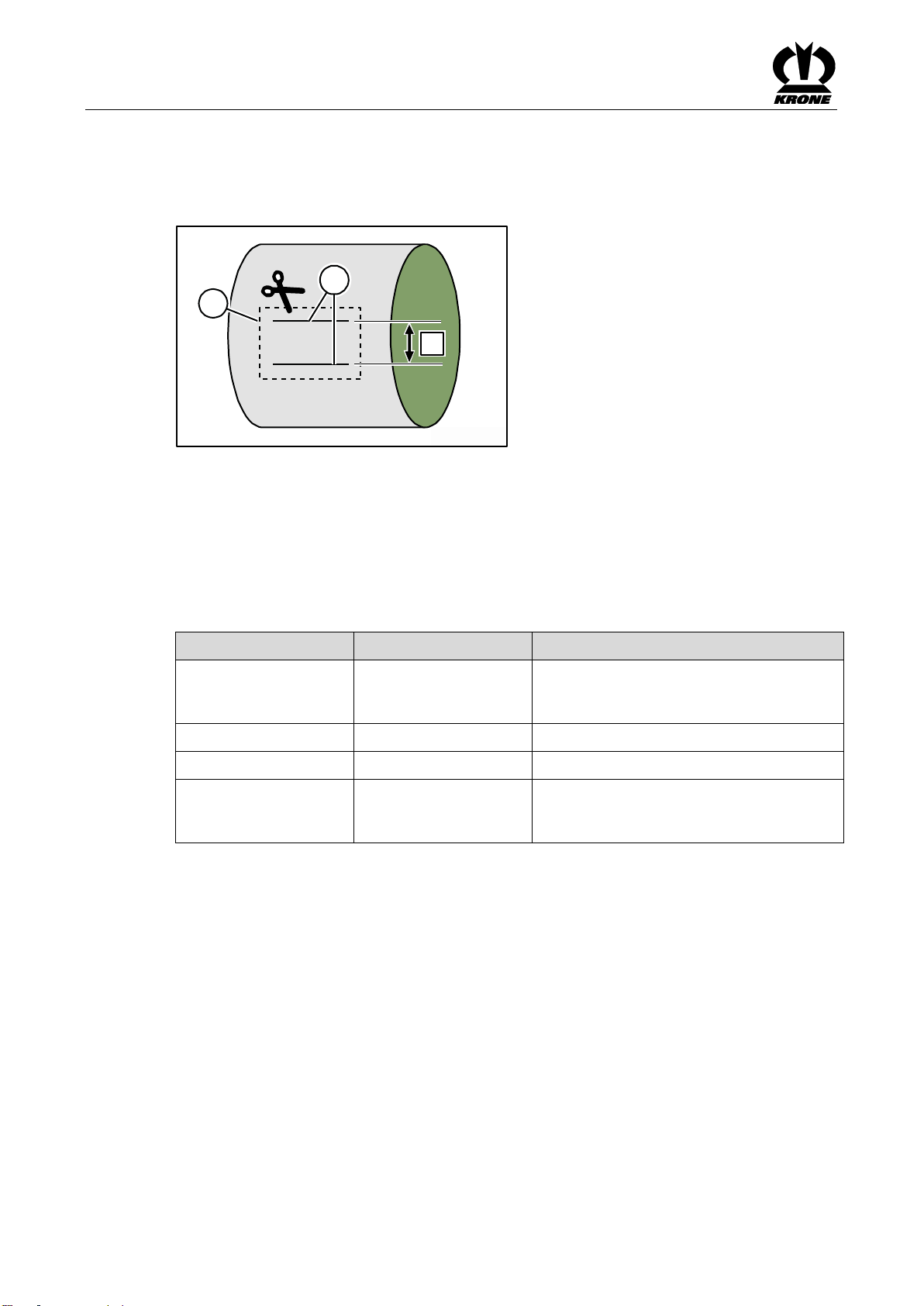

3.6.3 Setting Sensor B3 Net Motor Position ......................................................................................... 29

3.7 Checking Locking Lever on Net Blade ............................................................................................ 31

4Index ......................................................................................................................................................32

Pos: 3 /Layout Mo dule /---------------Seitenumbruch---------------- @ 0\mod_1196175311 226_0.docx @ 4165 @ @ 1