7

08-2022 20230616zm

IDEAL 7260 EN 9700241 9700181

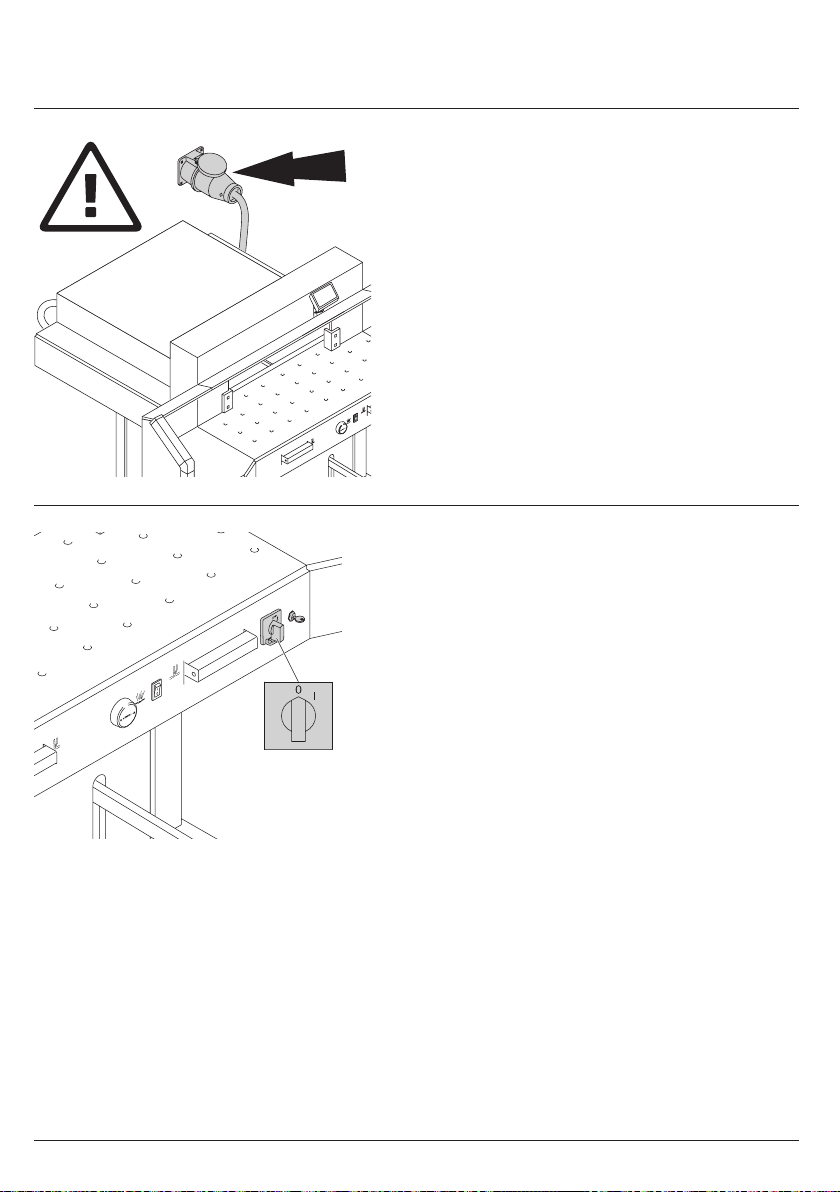

Protect mains cable against heat, oil and

sharp edges!

Standard machines are factory-set as follows:

• Power supply:

400 V, 3P+N+PE

220 V, 3P+PE

• Frequency 50 / 60 Hz.

Machine does not function

• Is the machine Eswitched on?

• Is the key-switch Don.

• Is the green overload switch apressed?

• Is the black overload switch bpressed?

• Check on-site fuse.

If the machine still does not function then the

rotation must be reversed.

The machine is wired according to the

IEC standards. We recommend that alterations

to the rotary direction be made in the socket.

It is also possible to make alterations in the

plug by exchanging "L1" and "L2".

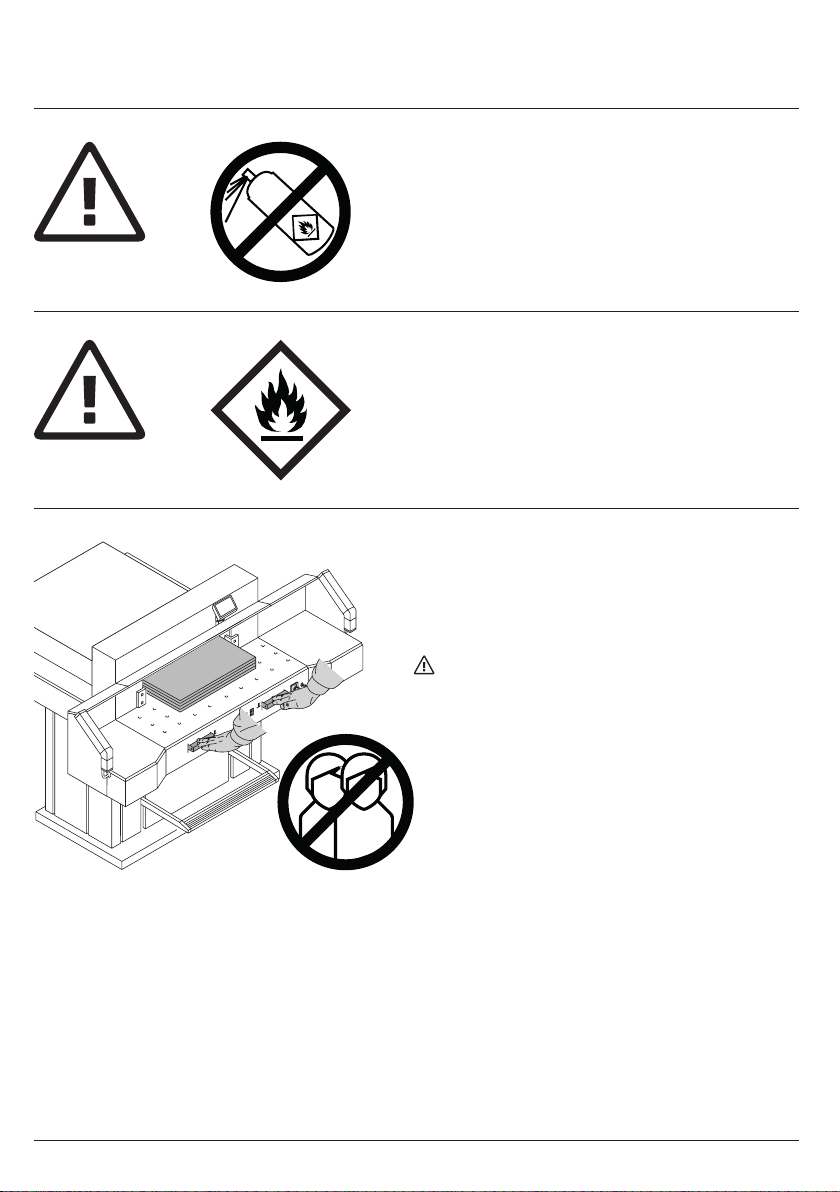

Danger!

Incorrect exchanging of the connections

will endanger the operator.

This work must be carried out by an

electrician.

Safety precautions