1

CONTENT

Chapter1Safety...................................................................................3

1Precautionsforsafety......................................................................3

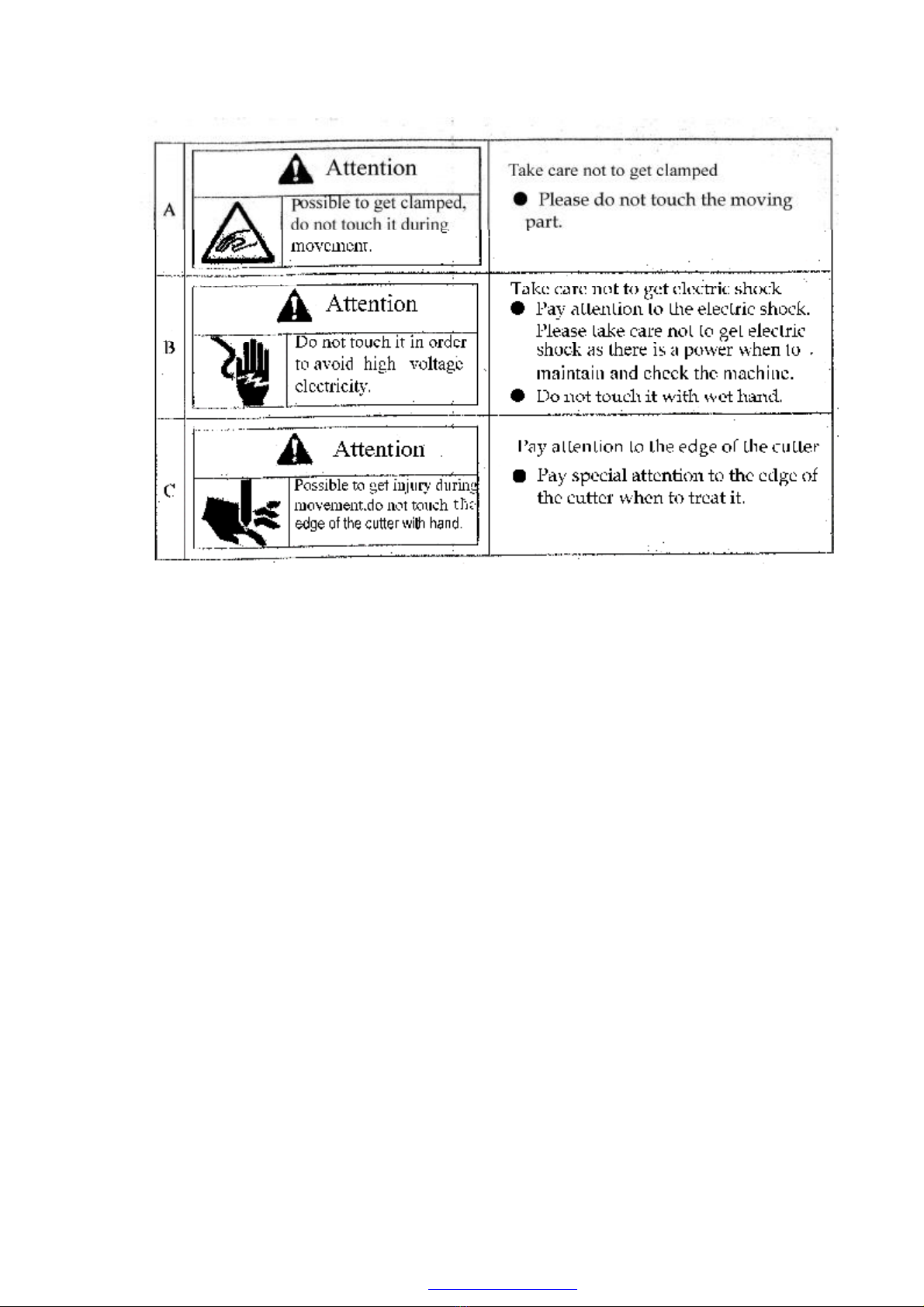

1-1Precautions forsafety.............................................................3

1-2Labelofwarning....................................................................3

2Safetydevice...................................................................................4

2-1Detailedrules.........................................................................4

Chapter2General.................................................................................5

1Outlineofmechanism.....................................................................6

1-1Purposeofuse........................................................................6

1-2Maintechnicalparameters......................................................6

1-3Accessories withthemachine.................................................7

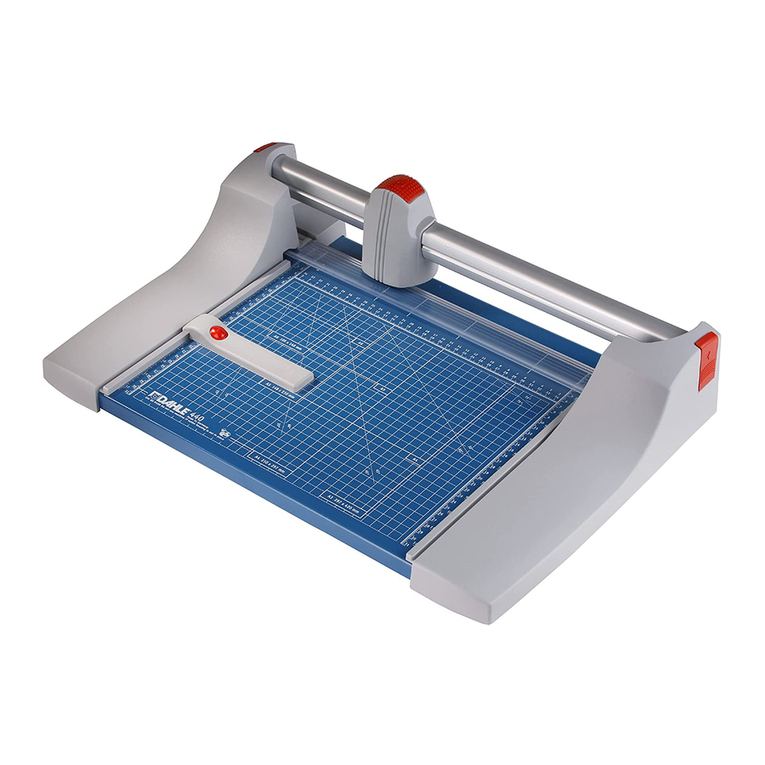

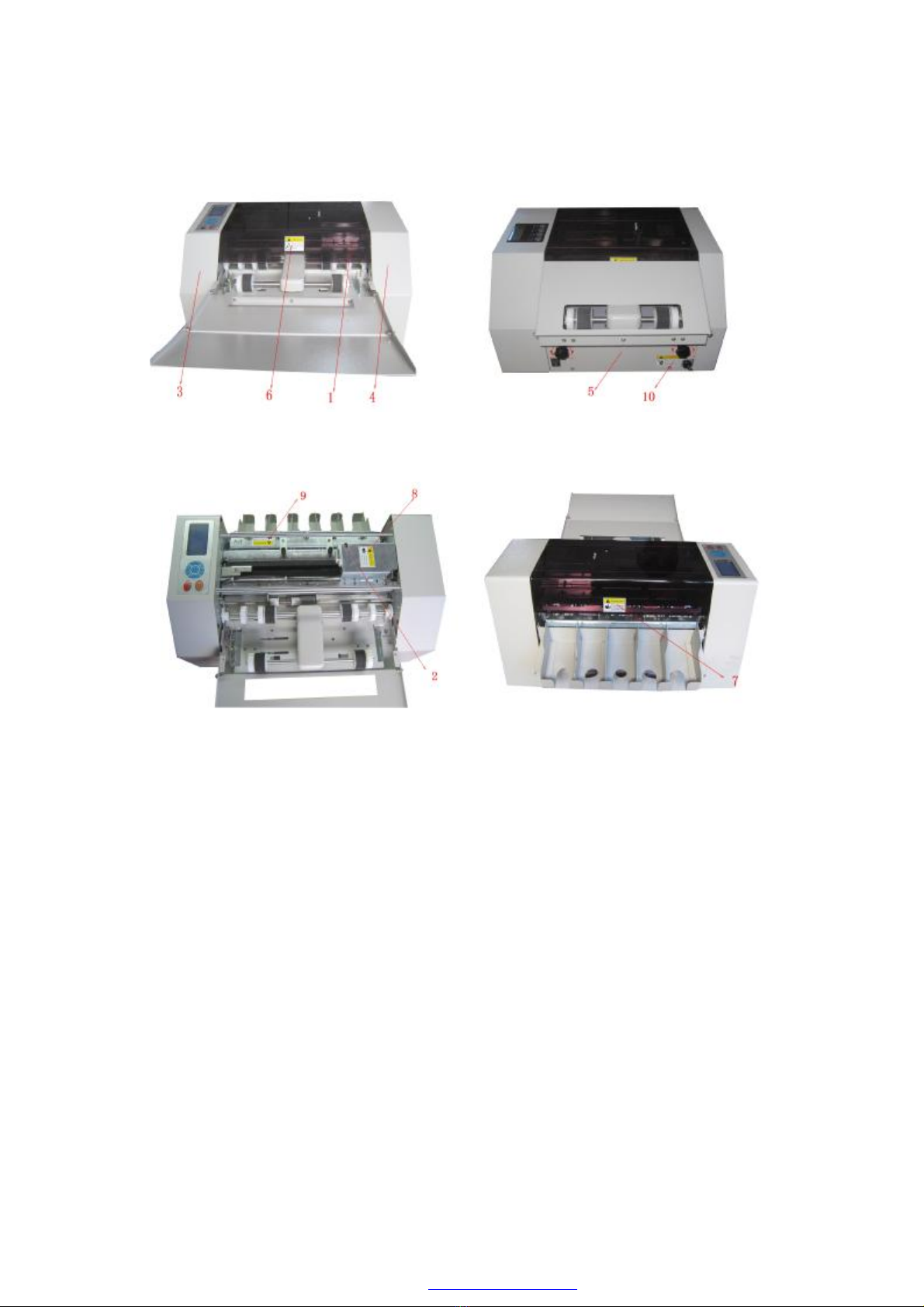

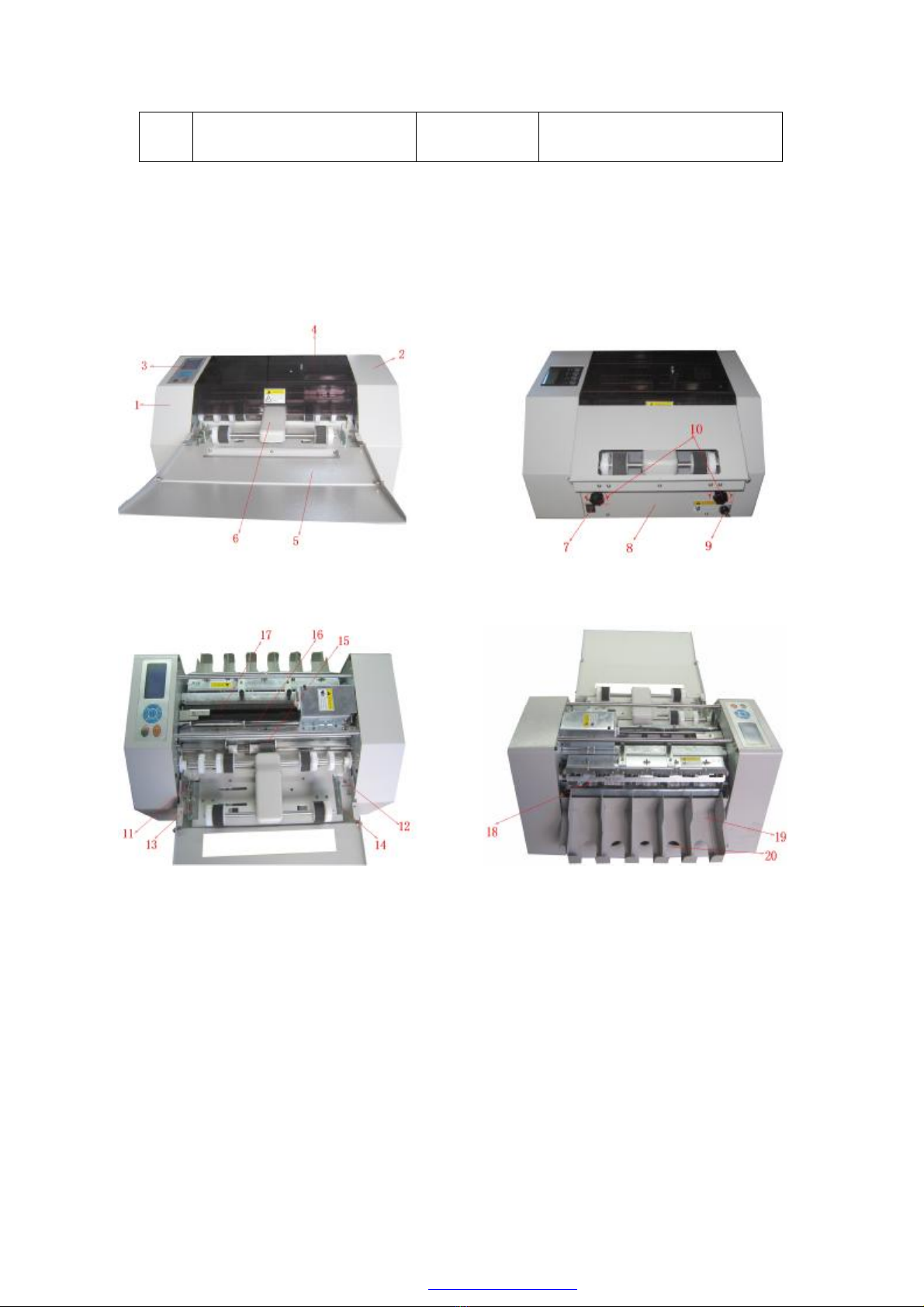

1-4Outlookdrawing....................................................................8

Chapter3Set-up,operationandmaintenance..................................9

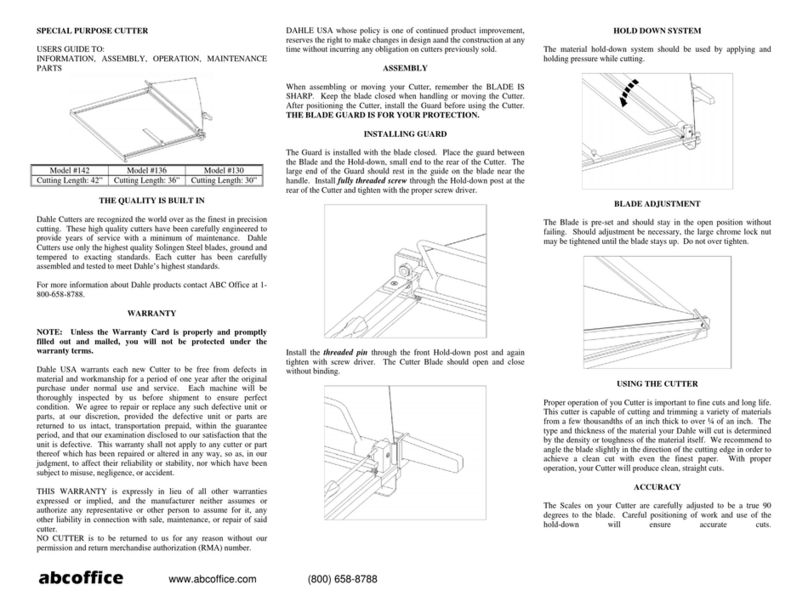

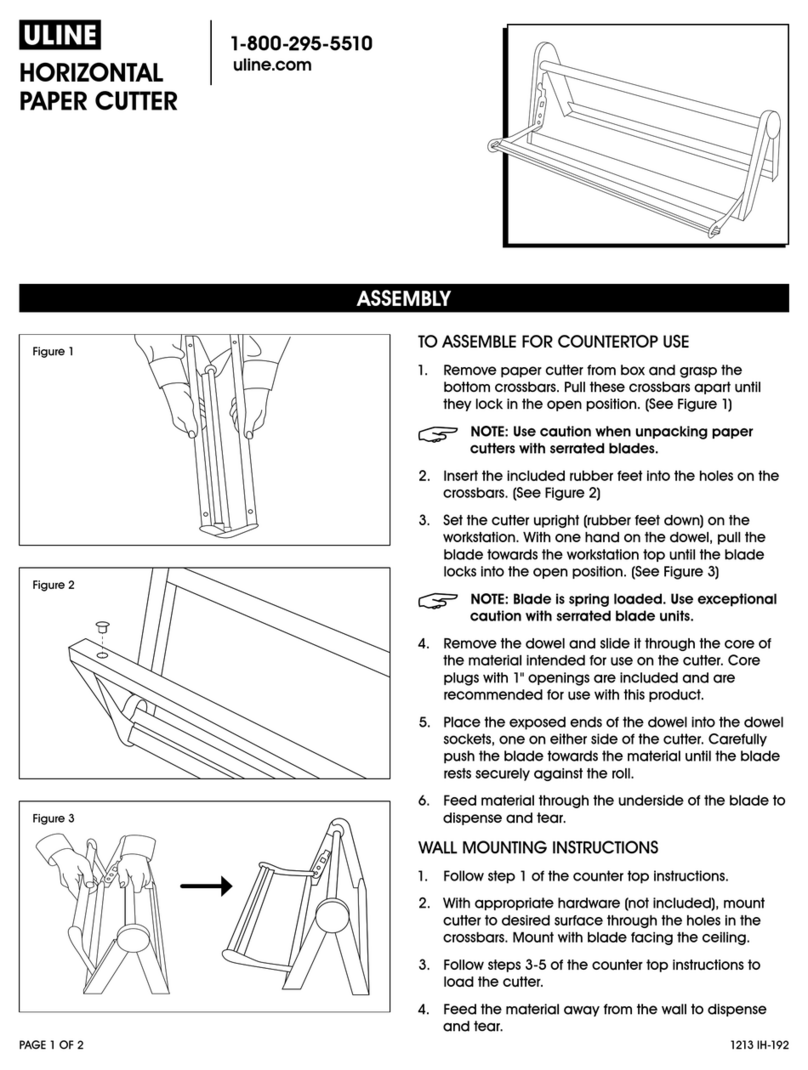

1Set-up..............................................................................................9

1-1Wayofset-upandflowsequence...........................................9

1-2Theplace andconditions wherethemachineis placed.........10

2Operation......................................................................................11

2-1Flowofcutting.....................................................................11

2-2Operationpanel....................................................................12

2-3Datumselection...................................................................13

2-4Cuttingmode........................................................................14

2-5Parameterset-up...................................................................27

2-6Wayofoperations andflow..................................................38

2-7Waytoloadandunloadthelongitudinalknifeassembly......40

2-8wayofadjustmenttocutdifferentthickness ofpaper...........42

3Troubleshooting............................................................................43

3-1safetycoverfails..................................................................43

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn