Contents

1. Safety guideline ……………………………………………………………………………… 3

1-1 Purpose of use …………………………………………………………………………… 3

1- Terms of use …………………………………………………………………………… 3

2. Product descriptions ………………………………………………………………………… 4

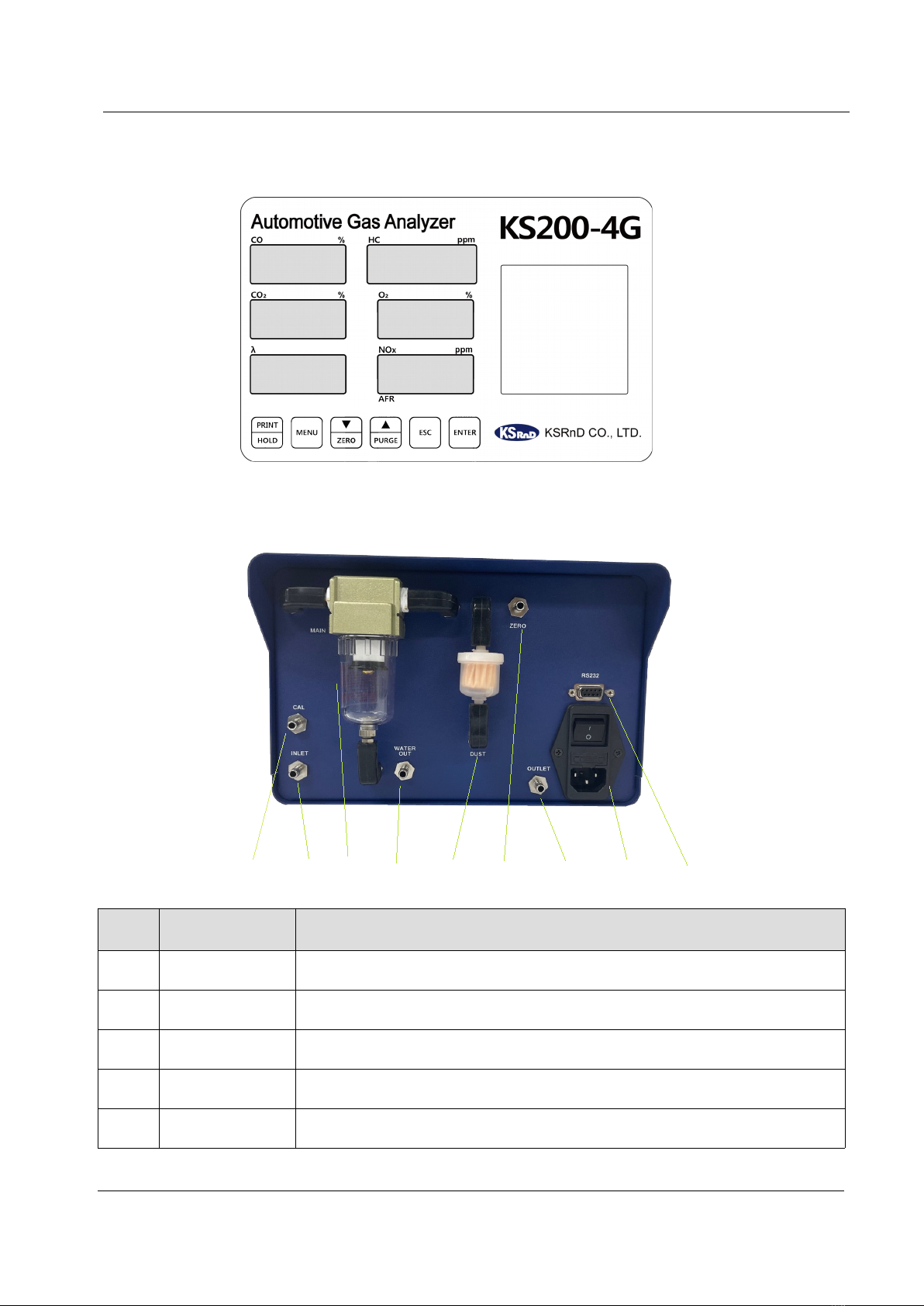

-1 Outlook …………………………………………………………………………………… 4

- Front Part …………………………………………………………………………………… 5

-3 Back Part …………………………………………………………………………………… 5

-4 Specification …………………………………………………………………………………… 6

3. Installation and precautions ……………………………………………………………… 7

3-1 How to install …………………………………………………………………………………… 7

4. Measure ent Mode…………………………………………………………………………… 8

4-1 Warm up ………………………………………………………………………………………… 8

4- Ready ……………………………………………………………………………………………… 9

4-3 Purge……………………………………………………………………………………………… 10

4-4 Measurement ………………………………………………………………………………… 10

4-5 Leak test …………………………………………………………………………………… 10

4-6 Print ………………………………………………………………………………………… 11

5. Select Mode ………………………………………………………………………………… 1

5-1 Key & Function ………………………………………………………………………………… 1

5- HC test ………………………………………………………………………………………… 13

5-3 Choice Fuel ……………………………………………………………………………………… 14

5-4 HCV , OCV , Ramda calculation …………………………………………………………… 14

5-5 PEF ………………………………………………………………………………………… 15

5-6 Set Date ………………………………………………………………………………………… 16

5-7 Calibrate gas……………………………………………………………………………………… 16

6. Others ………………………………………………………………………………………… 3

6-1 Flow diagram …………………………………………………………………………………… 3

6- Electric block diagram ………………………………………………………………………… 3

6-3 Dust filter………………………………………………………………………………………… 4

6-4 Probe …………………………………………………………………………………………… 5

6-5 Accessories………………………………………………………………………………………… 6