Note

Secochem-Ex

6

2.10.1 Marking

Motor (electric) II 2G Ex de IIC T.. Gb

Temperature class (T..): T6, T5, T4 or T3

The temperature class for the Secochem-Ex (SCX) model

supplied depends on pump selection and is indicated in the

data sheet and on the pump name plate.

In case of special coatings with a total film thickness

exceeding 0.2 mm: II 2G Ex de IIB T..Gb.

Hydraulic system (mechanical) II 2G c TX

Note:

DIN EN 13463--1, 2009--07, section ”9.3.2 Marking of

equipment complying with this standard”, stipulates that

pumps must be marked ”TX”.

Reason:

Where the actual maximum surface temperature depends

not on the equipment itself but mainly on operating

conditions (like a heated fluid in a pump), the manufacturer

must not apply a temperature class or temperature

marking. In such cases, the note ”TX” must be included in

the marking, and the relevant information must be

contained in the operating manual.

2.10.2 Unit fill

It is assumed that the system of suction and discharge

lines and thus the wetted pump internals are completely

filled with the product to be handled at all times during pump

operation, so that an explosive atmosphere is prevented.

Ifthe operator cannotwarrant this condition, appropriate

monitoring devices must be used (Directive 94/9/EC,

Annex II, Section 1.5.5 and EN 1127-1).

In addition, itis imperative to make sure thatthe

rotor space is properly filled (particularly if

barrier liquid is used or filters are fitted upstream of the pump).

The same applies to heating and cooling systems.

2.10.3 Drive

The canned motors may be connected to electricallow-voltage

grids with nominal voltages and voltage tolerances to IEC 38 or

other grids or power supply facilities with max. nominal voltage

tolerances of +/- 10 %.

For explosion--proof pump sets, the maximum permissible

supply voltage deviation is ¦5 % of the rated voltage. The

voltage difference between the individual phases must not

exceed 1 %.

Appropriate steps shall be taken to protect the canned motor

against overload. Motor overload protection can be realized by:

Limiting the current (e.g. by means of a motor protection

switch)

In this case,the rated current (see Fig. 1, name plate) must

be set. The running motor must be cut out at 1.2 times the

rated current at the latest (EN 60079-14).

Limiting the temperature by means of PTC resistors

integrated in the stator.

The PTC resistors must be connected to a tripping unit

which meets the requirements stipulated by Directive

94/9/EC, Annex II, Section 1.5.5 and EN 1127-1.

Exception: not permitted for motor DE90.2--1,1 in

combination with temperature class T6; for this

combination, motor overload protection by means of a

motor protection switch is mandatory.

When reaching the temperature limit stipulated for compliance

with the temperature class, the canned motor must be cut out

by means of an approved tripping unit (to Directive 94/9/EC)

connected to the measuring points provided.

The following measuring points are provided on the motor:

Monitoring concept I:

Temperature sensor in the bearing carrier (Part No. 382,

see general assembly drawing in the annex)

or

Monitoring concept II:

PTC resistor on the can and/or in the stator (fitted in the

factory).

The cutout temperature indicated on the name plate (TEX)must

be adhered to without fail.

In the case of monitoring concept I

(field TEX shows a number, see illustration of name plate)

the temperature sensor in the bearing carrier must be

connected and the cutout temperature (TEX) must be set.

In the case of monitoring concept II

(Field TEX does not show a number, see Fig. 1, name

plate.)

the PTC resistors must be connected to a tripping unit (as

per Directive 94/9/EC, see above).

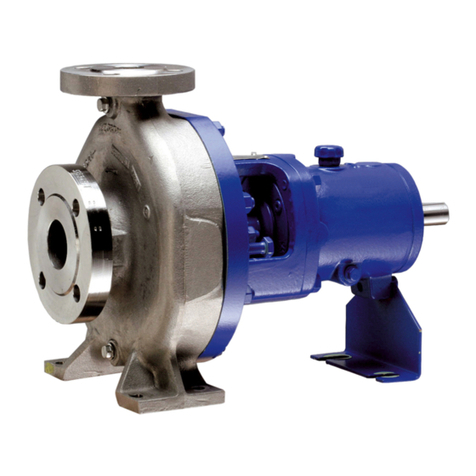

Cut-out temperature

of PT100

(number or --- )

Rated current

Explosion

protection

marking: Hydraulics

Explosion

protection

marking: Motor

Fig. 1 Name plate

The canned motors can also be operated on frequency

inverters. Make sure to observe the design data of the motor in

this case. To prevent an inadmissible heat build-up in the motor,

always use the motor version with PTC resistors integrated in

the stator when operating the pump unit with a frequency

inverter. The PTC resistors must be connected to a tripping unit

(also refer to sections 5.6 and 4.3.4).

If standstill heaters are used, make sure that the surface

temperatures of the canned motor do not exceed the

temperature class stated on the name plate.

The standstill heater offered by KSB is suited to the canned

motors described in this manual. Please observe the operating

manual supplied with the standstill heater.

2.10.4 Checking the direction of rotation (see also 6.1.2)

If the explosion hazard also exists during the installation

phase, the direction of rotation must never be checked

by starting up the unfilled pump unit, even for a short period, to

prevent temperature increases resulting from contact between

rotating and stationary components.

2.10.5 Pump operating mode

Make sure that the pump is always started up with the

suction-side shut-off valve fully open and the discharge-side

shut-off valve slightly open. However, the pump can also be

started up against a closed swing check valve. The

discharge-side shut-off valve shall be adjusted to comply with

the duty point immediately following the run-up process (see

6.1.5).