ROTO-JET PUMP

DISASSEMBLY/ASSEMBLY

VSR 175

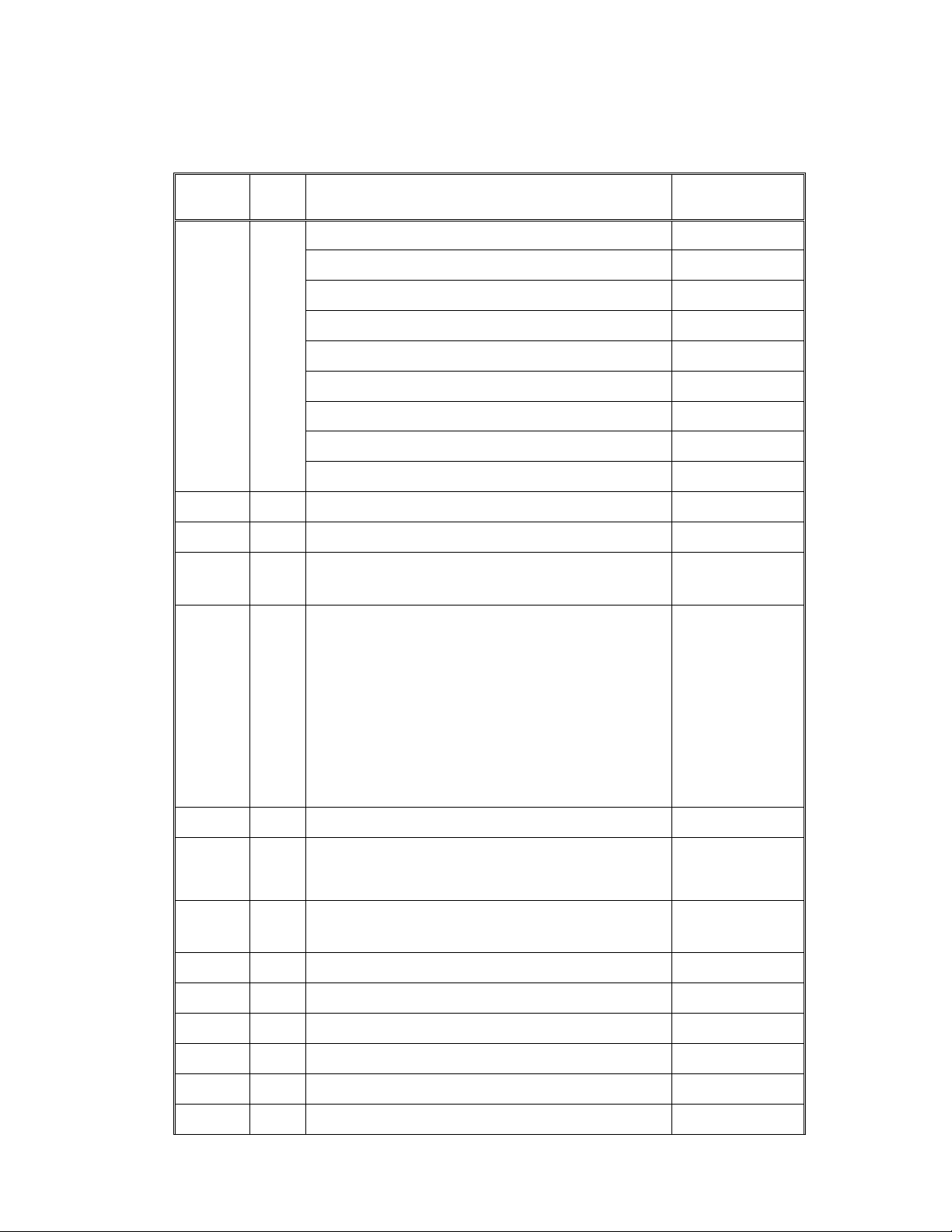

Table of Contents

i

1. GENERAL...............................................................................................................................................................................1

1.1 INTRODUCTION .........................................................................................................................................................1

1.2 ROTO-JET PUMP DESIGN ........................................................................................................................................1

1.3 PUMP IDENTIFICATION ............................................................................................................................................1

2. DISASSEMBLY/ASSEMBLY REFERENCE INFORMATION ..........................................................................................2

2.1 GENERAL ....................................................................................................................................................................2

2.2 RECOMMENDED TOOLS..........................................................................................................................................2

2.3 DISASSEMBLY/ASSEMBLY STANDS .....................................................................................................................4

2.4 VSR 175 3X2DIMENSIONAL DRAWINGS ...............................................................................................................6

2.5 3X2SECTION DRAWING ...........................................................................................................................................8

2.5.1. 3x2 EXPLODED VIEW (WET END ONLY).................................................................................................9

2.5.2. PUMP ROTATIONG ASSEMBLY..............................................................................................................12

2.5.2.1 Pump Rotating Assembly without Mounting Bolt Cover.............................................................12

2.5.2.2 PUMP ROTATIONG ASSEMBLY with Mounting Bolt Cover ....................................................14

2.5.3. SHAFT BEARING AND MOTOR ROTOR ASSEMBLY ..........................................................................16

2.5.4. STATOR HOUSING ASSEMBLY ..............................................................................................................18

2.5.5. SENSOR ASSEMBLY ................................................................................................................................20

2.5.6. FAN ASSEMBLY.........................................................................................................................................22

2.5.7. SHROUD ASSEMBLY................................................................................................................................23

2.5.8. TERMINAL BOX ASSEMBLY (POWER)..................................................................................................24

2.5.9. TERMINAL BOX ASSEMBLY INSTRUMENTATION ..............................................................................26

2.6 MECHANICAL SEAL AND PARTS LISTS...............................................................................................................28

2.6.1. 2-7/8” SINGLE SEAL (Only) .......................................................................................................................28

2.6.2. 3-1/2” SINGLE/DOUBLE SEAL..................................................................................................................29

2.7 SEAL SHIMMING ......................................................................................................................................................30

3. DISASSEMBLY/ASSEMBLY WET END ..........................................................................................................................31

3.1 PREPARATION FOR DISASSEMBLY ....................................................................................................................31

3.2 CAUTIONS.................................................................................................................................................................31

3.3 SEAL/MANIFOLD REMOVAL ..................................................................................................................................32

3.3.1. 2-7/8” Single Seal (Type S).........................................................................................................................32

3.3.2. 3-1/2” Single/Double Seal (Type SD).........................................................................................................32

3.4 ENDBELL REMOVAL ...............................................................................................................................................33

3.5 ROTOR COVOR AND PICK-UP TUBE REMOVAL................................................................................................33

3.6 ROTOR REMOVAL ...................................................................................................................................................34

3.7 ROTOR ASSEMBLY .................................................................................................................................................34

3.8 ROTOR COVER AND PICK-UP TUBE ASSEMBLY ..............................................................................................35

3.9 ENDBELL ASSEMBLY..............................................................................................................................................35

3.10 SEAL INSTALLATION...............................................................................................................................................36

3.10.1. 2-7/8” Single Seal (Only).............................................................................................................................36

3.10.2. 3-1/2” Single/Double Seal ...........................................................................................................................36

3.10.3. Seal Hub Replacement (Reference Figure 2.6.2) – 3-1/2” Seal Only .....................................................37

3.11 PICK-UP TUBE AND MANIFOLD INSTALLATION ................................................................................................37