Contents

3 of 38

MIL 90000

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Target group.....................................................................................................................................................6

1.3 Other applicable documents............................................................................................................................6

1.4 Symbols .............................................................................................................................................................6

1.5 Key to safety symbols/markings.......................................................................................................................6

2 Safety...................................................................................................................................................... 8

2.1 General..............................................................................................................................................................8

2.2 Intended use .....................................................................................................................................................8

2.3 Personnel qualification and training...............................................................................................................9

2.4 Consequences and risks caused by non-compliance with this manual .........................................................9

2.5 Safety awareness ..............................................................................................................................................9

2.6 Safety information for the operator/user.......................................................................................................9

2.7 Safety information for maintenance, inspection and installation ..............................................................10

2.8 Unauthorised modes of operation................................................................................................................10

3 Transport/Storage/Disposal ................................................................................................................ 11

3.1 Checking the condition upon delivery..........................................................................................................11

3.2 Transport.........................................................................................................................................................11

3.3 Storage/preservation......................................................................................................................................12

3.4 Return to supplier...........................................................................................................................................12

3.5 Disposal ...........................................................................................................................................................12

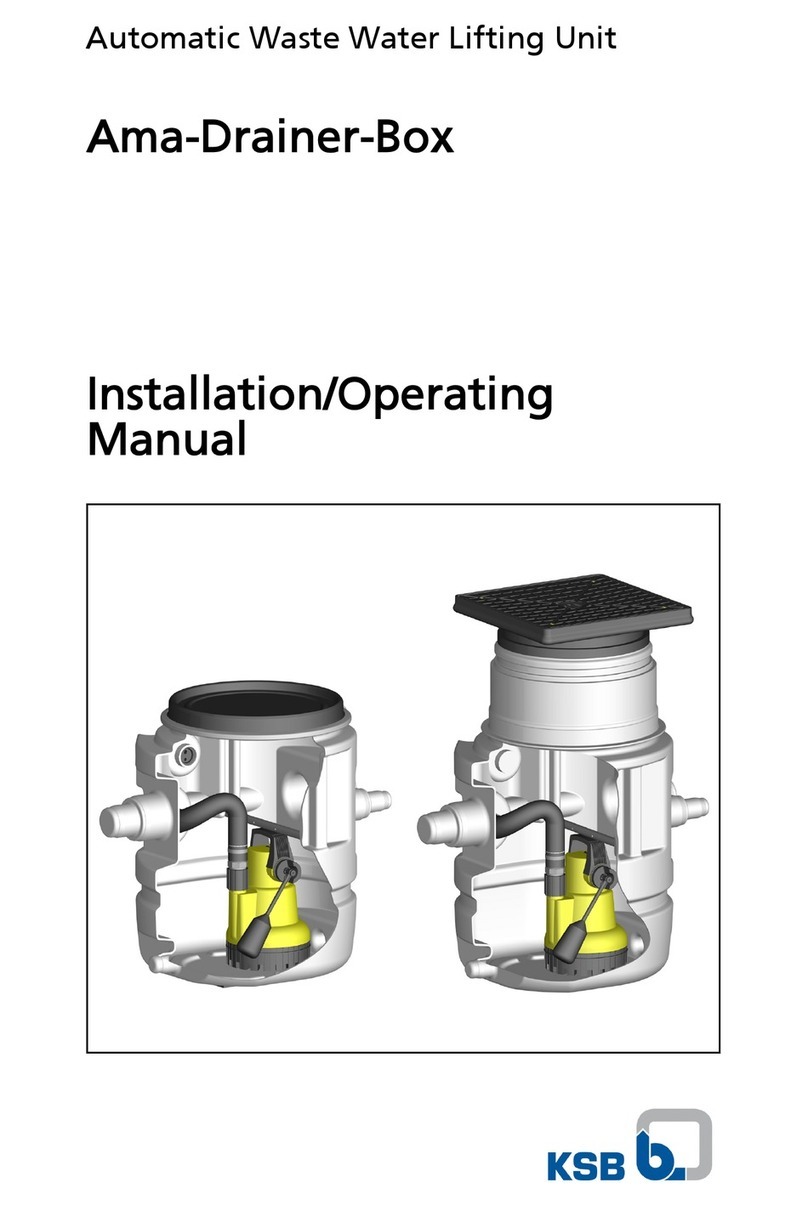

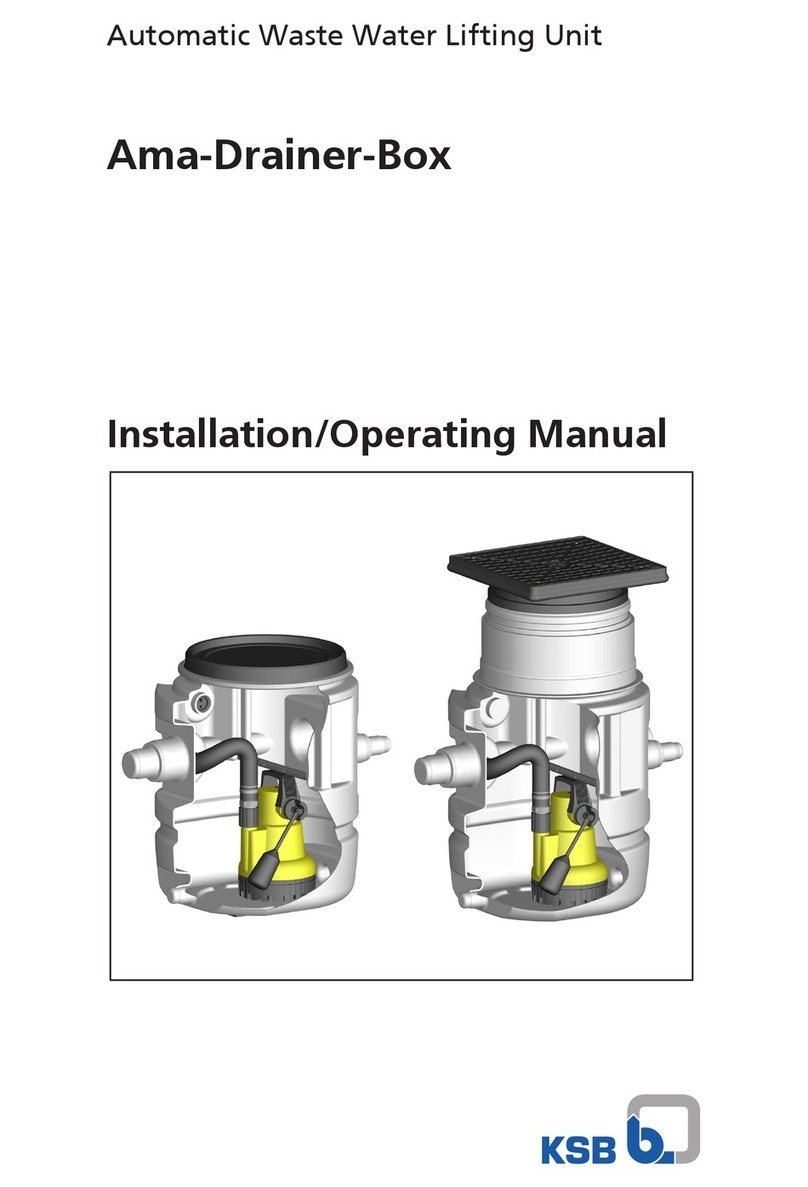

4 Description of the Valve...................................................................................................................... 13

4.1 General description ........................................................................................................................................13

4.2 Product information.......................................................................................................................................13

4.2.1 Product information as per Pressure Equipment Directive 2014/68/EU(PED)................................13

4.2.2 Product information as per Regulation No. 1907/2006(REACH) ....................................................13

4.3 Designation.....................................................................................................................................................14

4.4 Marking...........................................................................................................................................................15

4.5 Name plate......................................................................................................................................................16

4.6 Design details..................................................................................................................................................16

4.7 Function ..........................................................................................................................................................17

4.8 Scope of supply...............................................................................................................................................18

4.9 Noise characteristic.........................................................................................................................................18

5 Installation at Site................................................................................................................................ 19

5.1 General information/Safety regulations .......................................................................................................19

5.2 Installation position........................................................................................................................................19

5.3 Preparing the valve ........................................................................................................................................20

5.4 Piping ..............................................................................................................................................................20

5.4.1 Flange connection..............................................................................................................................20

6 Commissioning/Start-up/Shutdown................................................................................................... 21

6.1 Commissioning/Start-up.................................................................................................................................21

6.1.1 Prerequisites for commissioning/start-up .........................................................................................21

6.1.2 Starting up the system.......................................................................................................................21

6.2 Operating limits..............................................................................................................................................21

6.2.1 Pressure/temperature ratings............................................................................................................21

6.2.2 Ambient temperature........................................................................................................................22

6.3 Shutdown........................................................................................................................................................22

6.3.1 Measures to be taken for shutdown ................................................................................................22

7 Servicing/Maintenance........................................................................................................................ 23

7.1 Safety regulations...........................................................................................................................................23