Contents

3 of 72

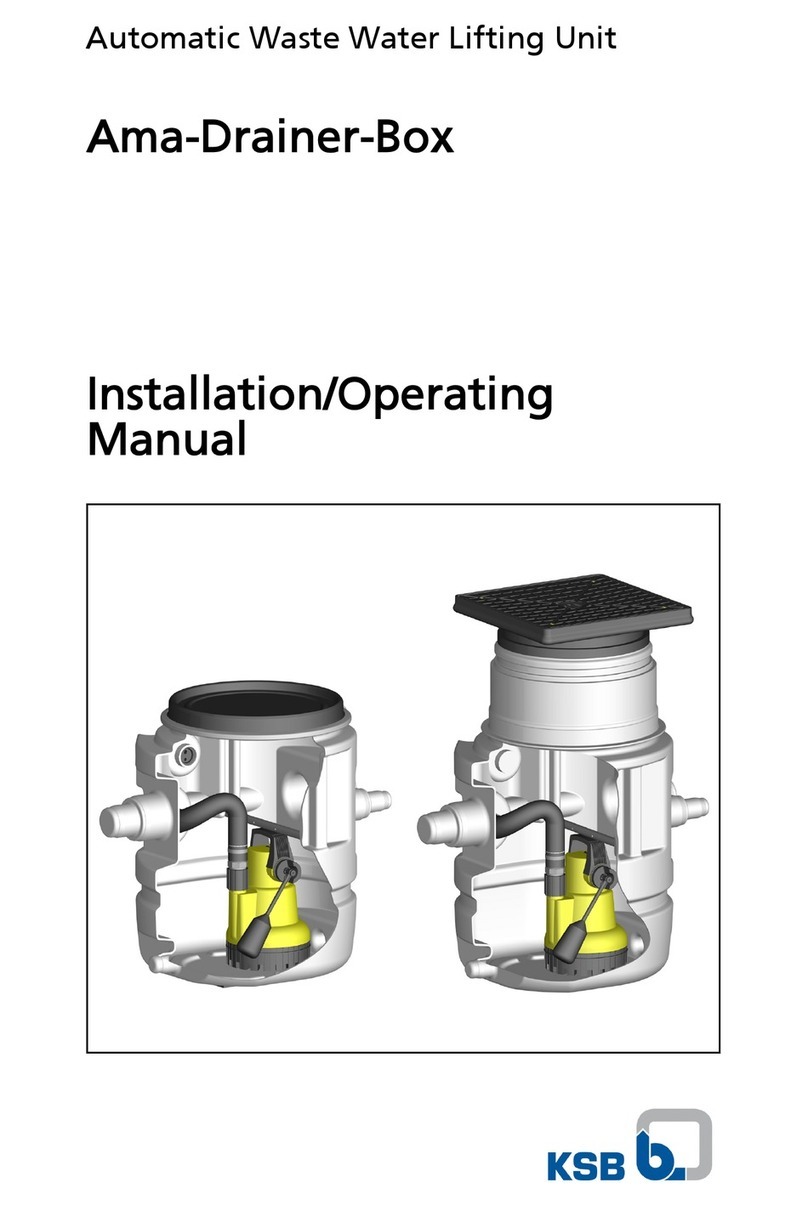

Ama-Drainer-Box

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Installation of partly completed machinery....................................................................................................6

1.3 Target group.....................................................................................................................................................6

1.4 Other applicable documents............................................................................................................................6

1.5 Symbols .............................................................................................................................................................6

2 Safety...................................................................................................................................................... 7

2.1 Key to safety symbols/markings.......................................................................................................................7

2.2 General..............................................................................................................................................................7

2.3 Personnel qualification and training...............................................................................................................7

2.4 Consequences and risks caused by non-compliance with this manual .........................................................8

2.5 Safety awareness ..............................................................................................................................................8

2.6 Safety instructions for the operator/user........................................................................................................8

2.7 Safety information for maintenance, inspection and installation ................................................................8

2.8 Unauthorised modes of operation..................................................................................................................8

2.9 Intended use .....................................................................................................................................................9

3 Transport/Temporary Storage/Disposal............................................................................................. 10

3.1 Checking the condition upon delivery..........................................................................................................10

3.2 Transport.........................................................................................................................................................10

3.3 Storage/preservation......................................................................................................................................10

3.4 Return to supplier...........................................................................................................................................10

3.5 Disposal ...........................................................................................................................................................11

4 Description............................................................................................................................................ 12

4.1 General description ........................................................................................................................................12

4.2 Designation.....................................................................................................................................................12

4.3 Name plate......................................................................................................................................................12

4.4 Design details..................................................................................................................................................12

4.5 Configuration and function...........................................................................................................................13

4.6 Fluids handled.................................................................................................................................................14

4.7 Scope of supply...............................................................................................................................................14

4.8 Dimensions and weights ................................................................................................................................16

5 Installation at Site................................................................................................................................ 17

5.1 Safety regulations...........................................................................................................................................17

5.2 Checks to be carried out prior to installation...............................................................................................17

5.3 Installing the lifting unit................................................................................................................................18

5.3.1 Installing the underfloor box ............................................................................................................18

5.3.2 Connect the underfloor box piping..................................................................................................19

5.3.3 Fitting the level-adjusting piece or the puddle flange with level-adjusting piece (not included in

the scope of supply)...........................................................................................................................24

5.3.4 Fitting MK400 and MK630 puddle flanges (not included in the scope of supply) ......................24

5.3.5 Backfilling around the tank ..............................................................................................................25

5.3.6 Fitting the sealing collar....................................................................................................................27

5.4 Installing the above-floor lifting unit ...........................................................................................................29

5.4.1 Installing the above-floor box...........................................................................................................29

5.4.2 Connecting the above-floor box piping ...........................................................................................30

5.5 Installing the submersible motor pump(s)....................................................................................................33

5.5.1 Single-pump units ..............................................................................................................................33

5.5.2 Dual-pump units ................................................................................................................................39

5.6 Fitting the cover plate/cover..........................................................................................................................43

5.7 Venting device with activated carbon filter (accessories)............................................................................45

6 Commissioning/Start-up/Shutdown................................................................................................... 47

6.1 Commissioning/Start-up.................................................................................................................................47