Contents

1 Safety Precautions ............................................................................................................................. 1

1.1 Transport.................................................................................................................................... 1

1.2 Storage....................................................................................................................................... 1

1.3 Installation .................................................................................................................................. 2

1.4 Operating ................................................................................................................................... 2

1.5 Maintenance............................................................................................................................... 3

2 Product Description ........................................................................................................................... 4

2.1 Product Introduction ................................................................................................................... 4

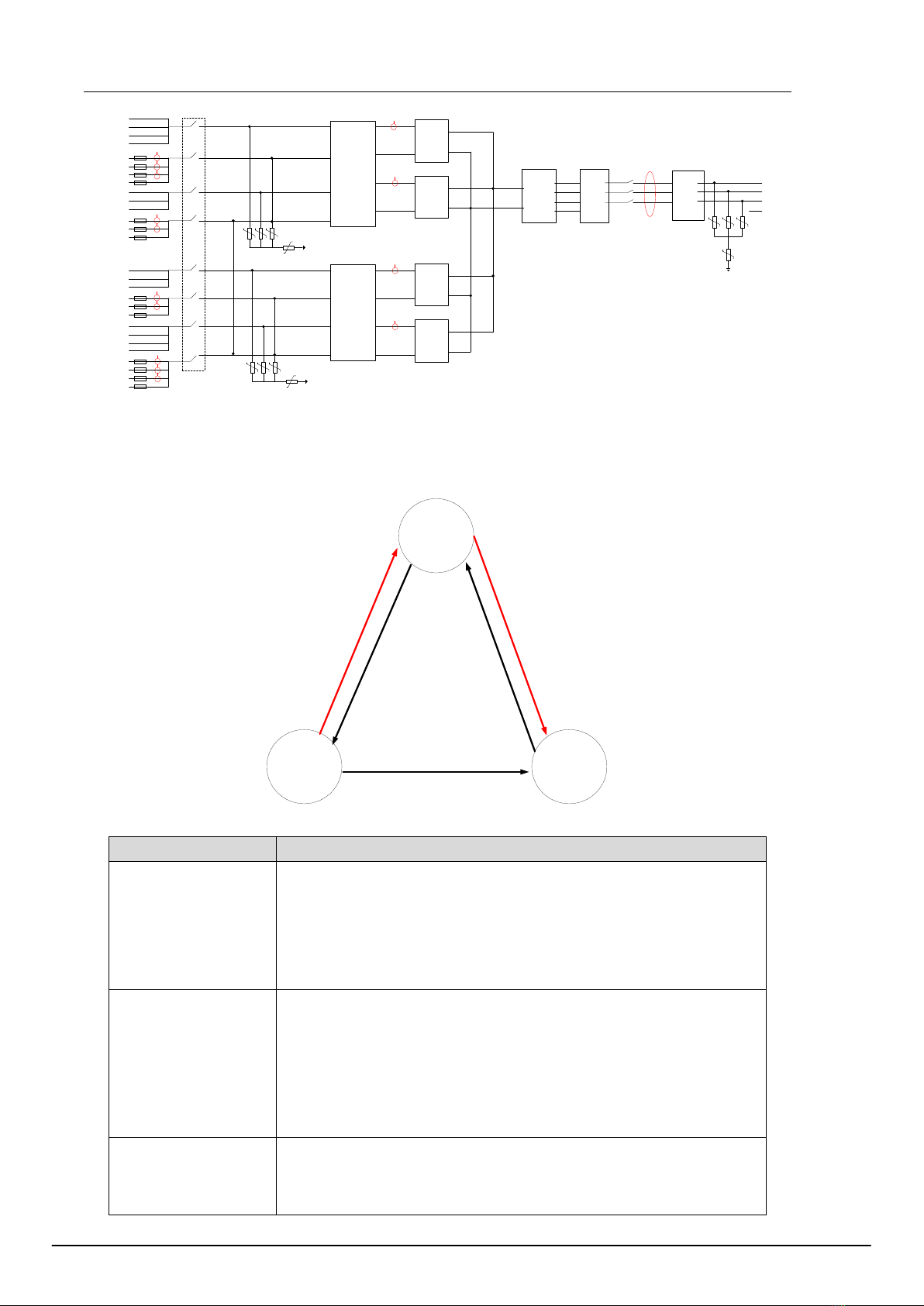

2.1.1 Schematic Diagram ........................................................................................................................ 4

2.1.2 Operating Mode.............................................................................................................................. 5

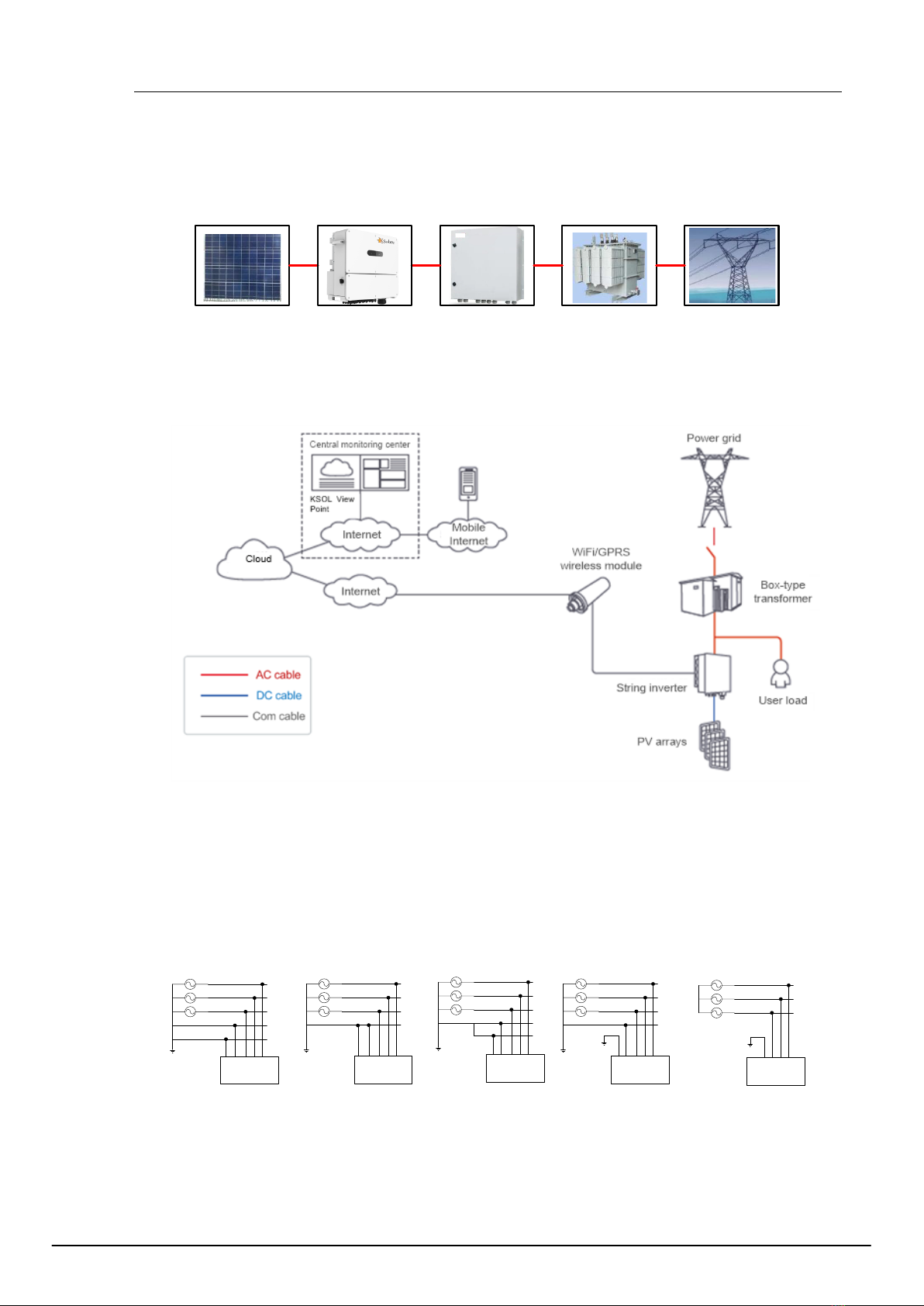

2.2 System Configuration and Application....................................................................................... 6

2.2.1 Application Description................................................................................................................... 6

2.2.2 Supported Grid Form...................................................................................................................... 6

2.3 Naming Rules............................................................................................................................. 7

2.4 Nameplate Label ........................................................................................................................ 7

2.5 Inverter Configuration ................................................................................................................ 7

2.6 Labels on the Package ............................................................................................................ 9

2.7 Warning Signs on the Inverter ................................................................................................. 9

3 System Installation ........................................................................................................................... 11

3.1 Unpack and Inspect ................................................................................................................. 11

3.2 Installation Tool Preparation .................................................................................................... 11

3.3 Installation Environment Requirements ................................................................................... 11

3.4 Reserved Space Requirement................................................................................................. 12

3.5 Installation Method ................................................................................................................... 13

3.5.1 Pole Mounting with Hoops............................................................................................................ 13

3.5.2 Pole Mounting with Screws .......................................................................................................... 13

3.5.3 Wall/Bracket Mounting ................................................................................................................. 13

3.6 Electrical Connections ............................................................................................................. 14

3.6.1 Cable Requirements..................................................................................................................... 14

3.6.2 Cable Selection ............................................................................................................................ 15

3.6.5 Connect the Ground Wire............................................................................................................. 15

3.6.6 Open the Lower Door Panel ......................................................................................................... 16

3.6.7 Connect the AC Output Cable ...................................................................................................... 16

3.6.8 Connect Communication Cable.................................................................................................... 17

3.6.9 Connect the DC Input Cable ........................................................................................................ 17

4 Commissioning Guide ..................................................................................................................... 20

4.1 Check before Power On........................................................................................................... 20

4.2 System Power On .................................................................................................................... 20

4.3 System Power Off .................................................................................................................... 20

5 Fault and Troubleshooting .......................................................................................................... 29

5.2 Troubleshooting ....................................................................................................................... 30