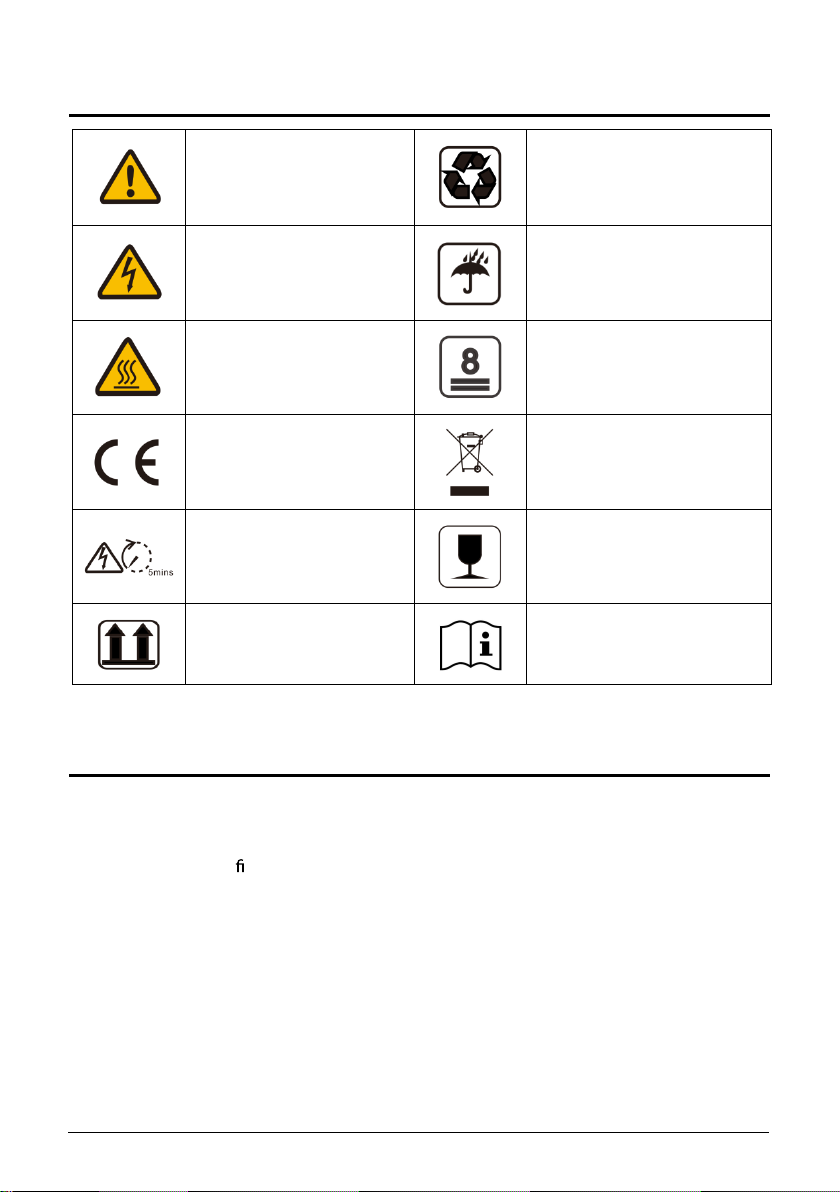

1. SYMBOLS ON THE LABEL

2. SAFETY AND WARNINGS

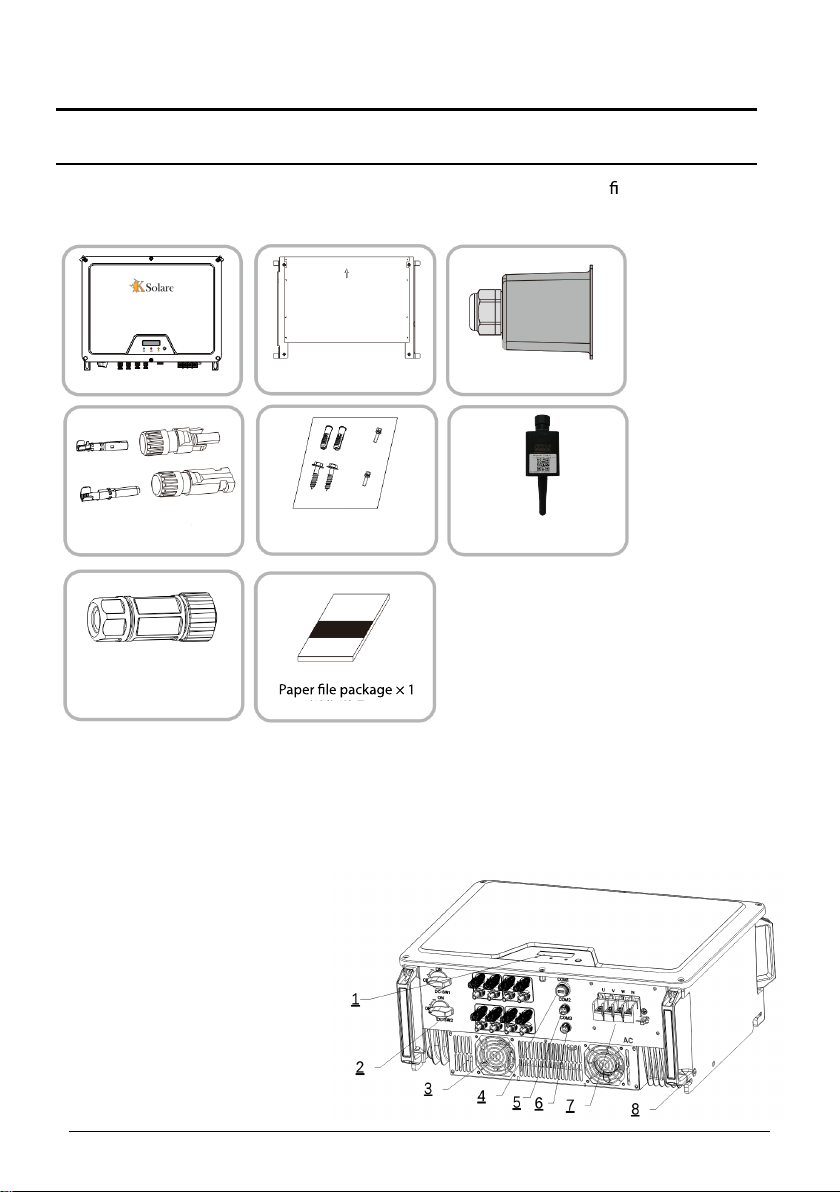

3. 3UNPACKING

3. 1 Scope of Delivery .......................................... .................................................... 5

3. 2 Product Overview ................................................................................... ......... 5

4. 4INSTALLING

4.1 Installation Requirement ............................................................................. 6

4. 2 Mo unting Location ........................................................................................ 7

4. 3 Mounting ................................................................................... ....................... 7

4. 4 Installing the secondary PE cable ........................................................ 8

5. 5COMMISSIONING

5.1 Safety Instructions ........................................................................................... 10

5.2 AC Wire Assembly and Connection ....................................................... 10

5.2.1 AC Commissioning ........................................................................................ 10

5. 3 DC Wire Assembly and Connection ...................................................... 13

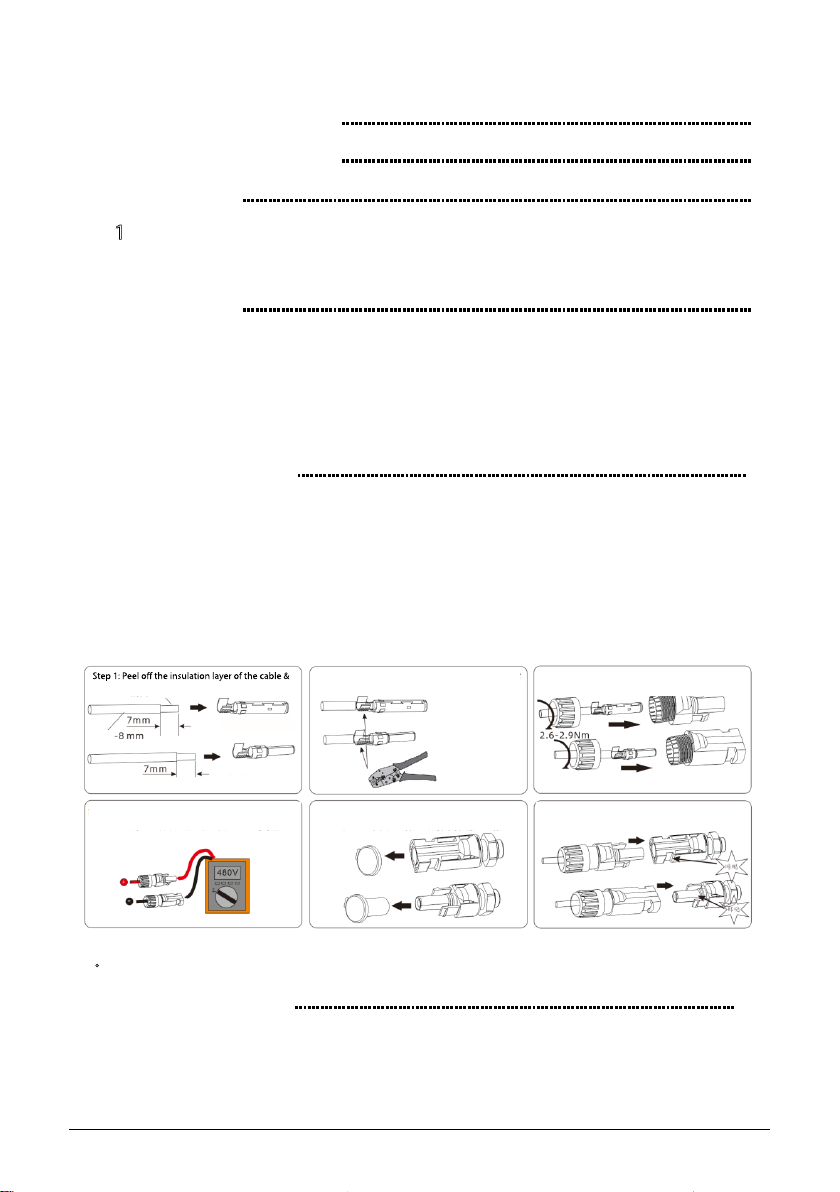

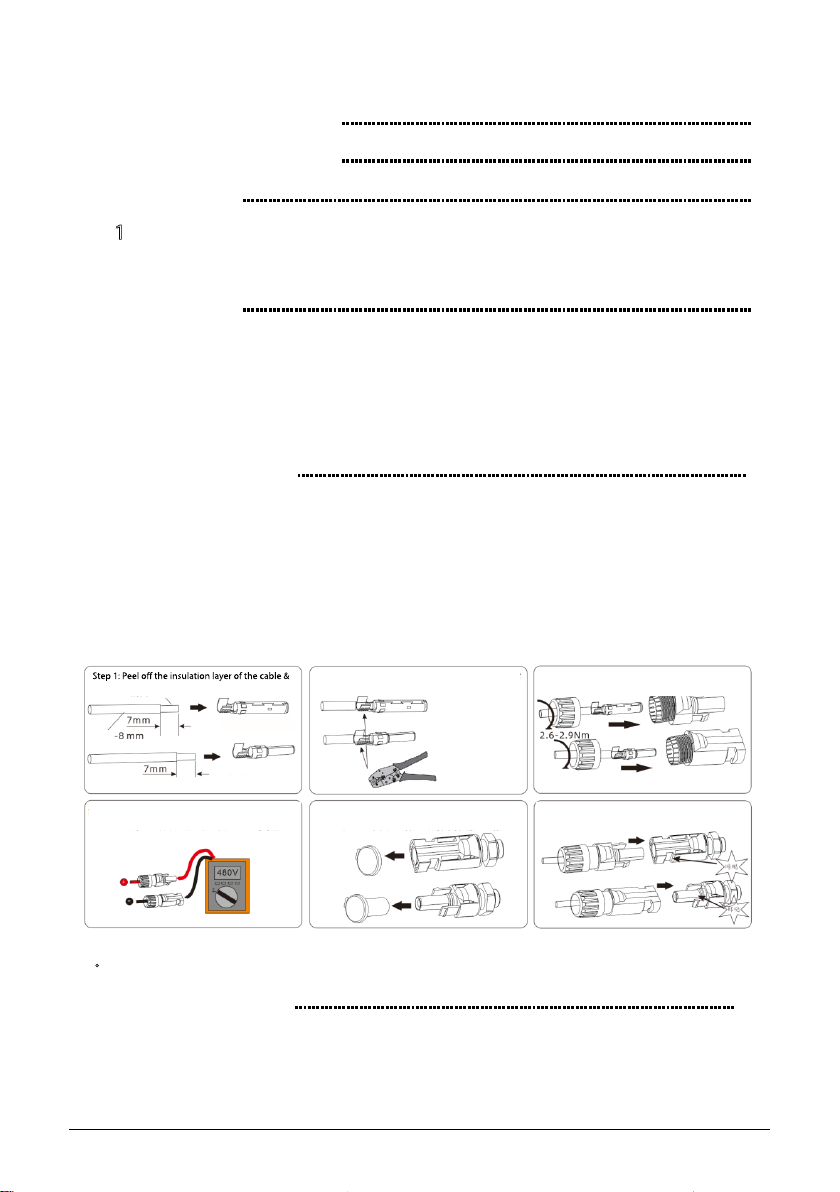

DC Commissioning :

insert it into the corresponding terminal

Positive cold-pressed

terminal

Negative cold-press

terminal

Diameter

Step 2 : Use a suitable crimping pliers to crimp the

corresponding wire

Step 3: Insert the crimped terminal into the corresponding

plastic shell

Step 6: Connect the wired client and machine

Step 4: Check whether the polarity of the connecting cables of the PV string is

correct, and ensure that the open circuit voltage does not exceed the upper

limit of the inverter input

Step 5: Pull out the dustproof cap on the DC terminal of the machine

Note: Please keep the dustproof cap of the unused terminal

5. 4 Residual Current Protection ................................................................ 13

6. 6 COMMUNICATION

6.1 System monitoring via Datalogger -RS485/Wi-Fi/GPRS (Optional) .... 14

1

Table Of Content

3

3

5

14

6