CATALOGUE

1. SYMBOLS ON THE LABEL ..................................................................................3

2. SAFETY AND WARNINGS ..................................................................................3

3. UNPACKING .........................................................................................................4

3.1 Scope of Delivery ..............................................................................................................5

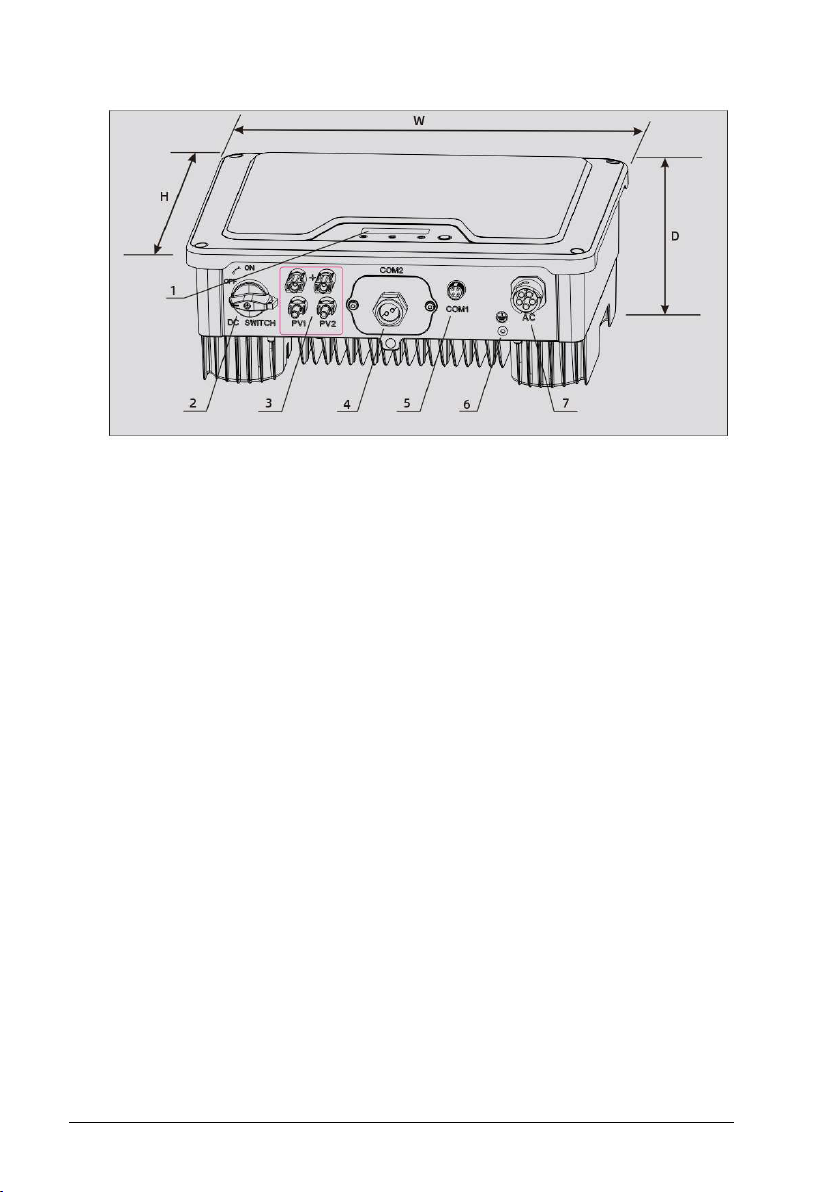

3.2 Product Overview .............................................................................................................5

4. INSTALLING .........................................................................................................6

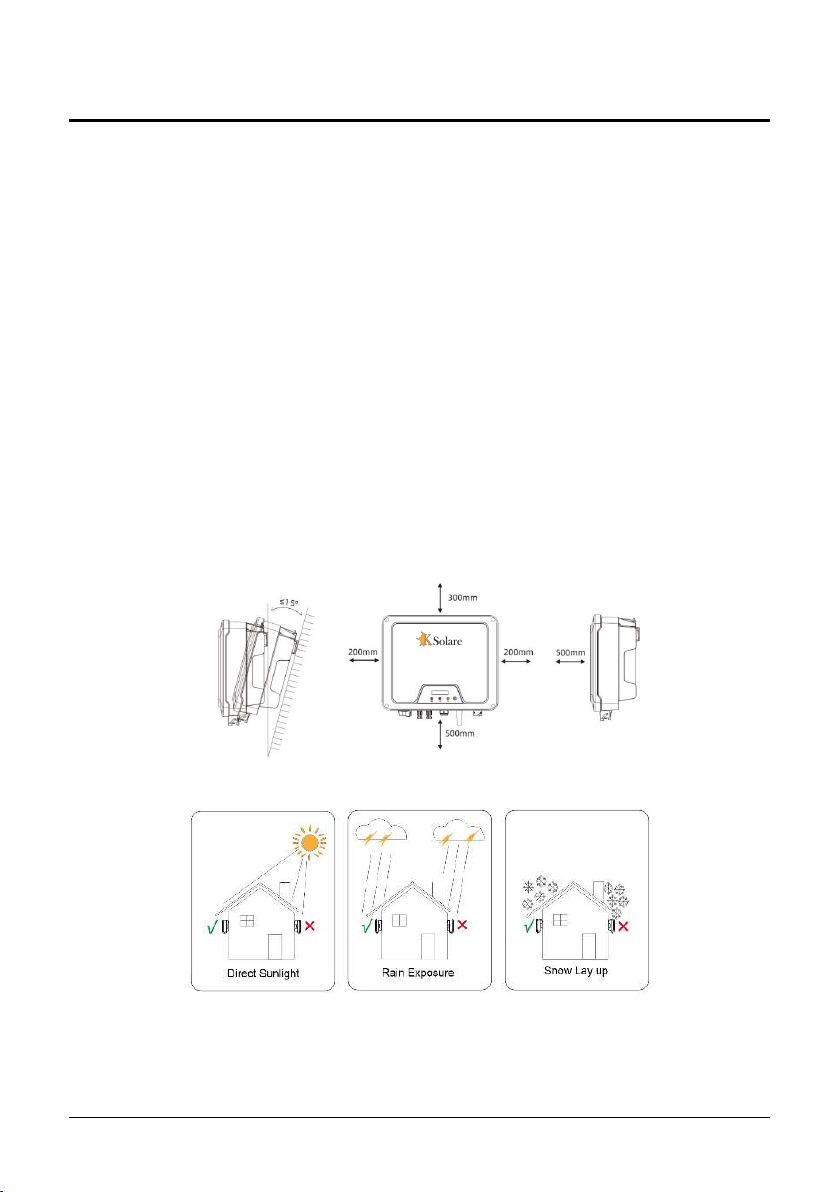

4.1 Installation Requirement ..................................................................................................6

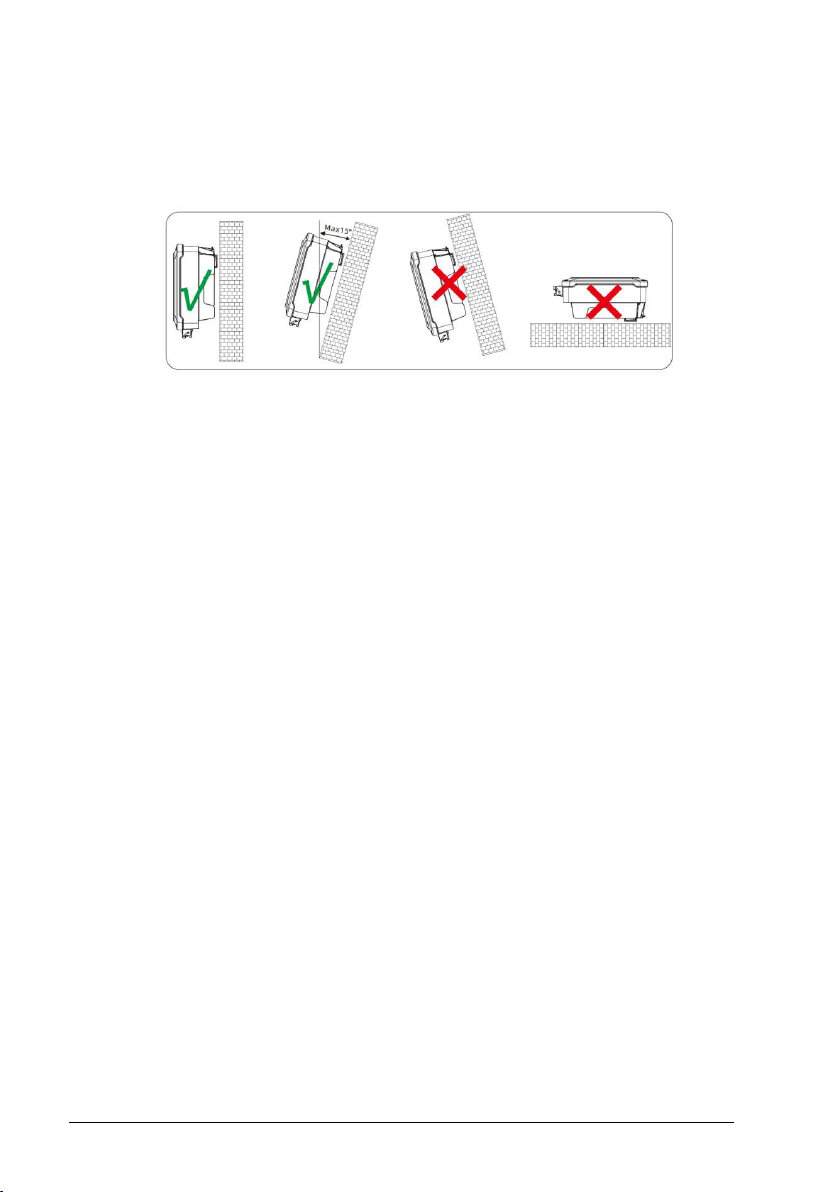

4.2 Mounting Location...........................................................................................................7

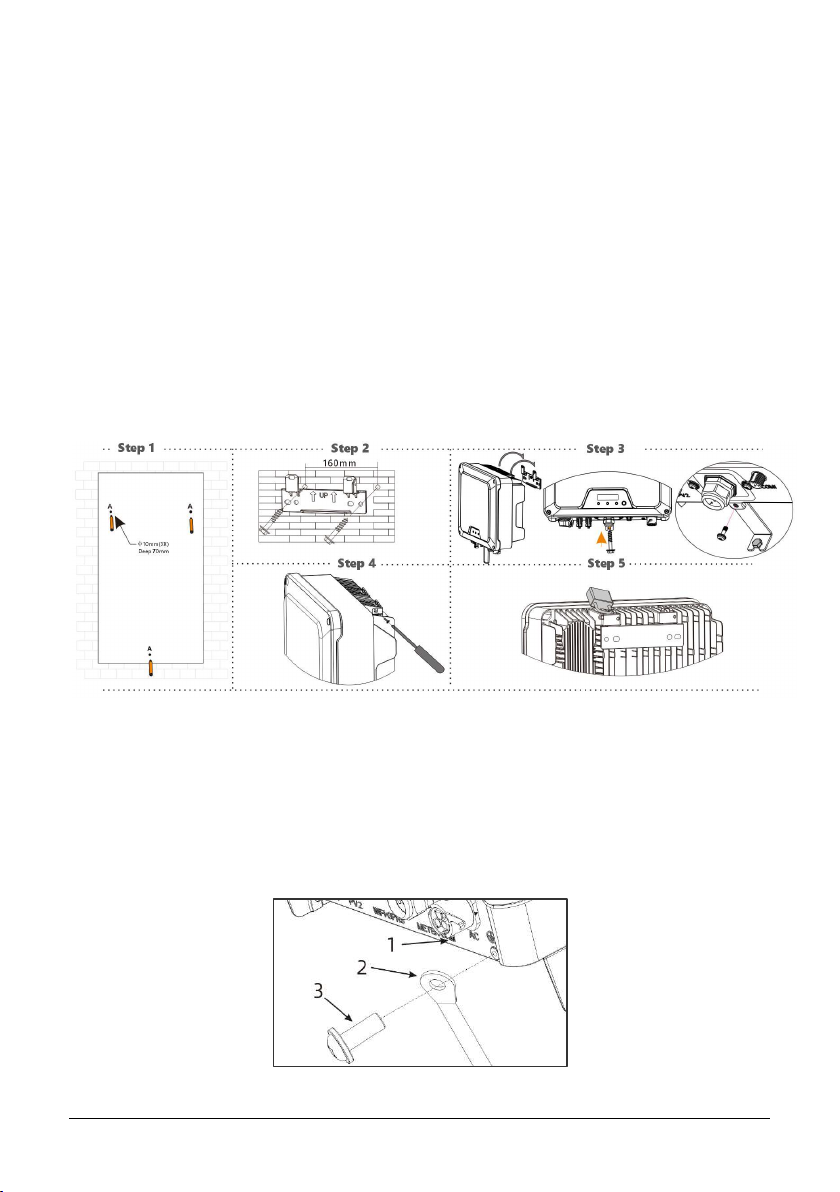

4.3 Mounting ...........................................................................................................................8

4.4 Installing the PE cable ......................................................................................................8

5. COMMISSIONING .............................................................................................9

5.1 Safety Instructions ..........................................................................................................9

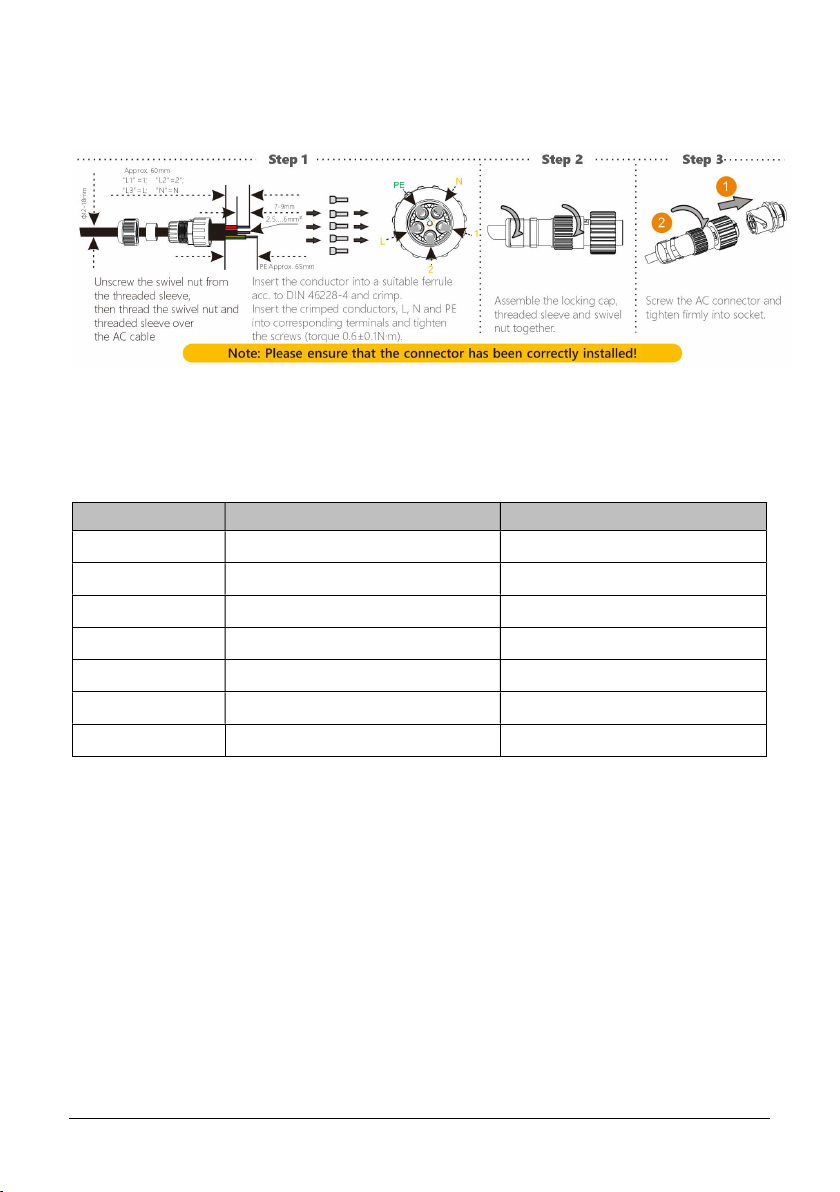

5.2 AC Wire Assembly and Connection ..............................................................................10

5.3 DC Wire Assembly and Connection ..............................................................................11

5.4 Residual Current Protection ...........................................................................................11

6. COMMUNICATION ...........................................................................................12

6.1 System monitoring via Datalogger - RS485/Wi-Fi /GPRS (Optional) ........................12

7. START UP AND OPERATION ...........................................................................14

7.1 Safety Check Before Start Up .........................................................................................14

7.2 Inverter LED Indicators ...................................................................................................15

8. DISCONNECTING FROM VOLTAGE RESOURCES .........................................16

10.

SYSTEM MAINTENANCE ..............................................................................19

9. Fault Finding ..............................................................................17