1.4.1 Hazard Information

1.3.4.Setting of Warning Sign for Safety

This sign indicates a hazardous situation which, if not avoided,

could result in death or serious injury!

This sign shows danger of hot surface!

Refer to the operating instructions.

The E8KT/E10KT/E12KT must not be touched or put into service until

5 minutes after it has been switched off or disconnected to prevent an

electric shock or injury.

During instruction, maintenance and repair, follow the instructions below to prevent

non-specialist personnel from causing misuse or accident:

Obvious signs should be placed at front switch and rear switch to prevent accidents caused

by false switching.

Warning signs should be set near operating areas.

The system must be reinstalled after maintenance or operation.

To ensure the electrical parameters to match requirements, related measuring equipment are

required when the system is being connected or tested.

Ensure that the connection and use matched specification to prevent electric arcs or shocks.

It is very likely that moisture may cause damages to the system. Repair or maintaining

activities in wet weather should be avoided or limited.

The battery system is part of the energy storage system which stores life-threatening high

voltage even when the DC side is switched off. Touching the battery outlets is strictly

prohibited. The inverter can keep a life-threatening voltage even after disconnecting it from the

DC and / or AC side. Therefore, for safety reasons, it must be tested with a properly calibrated

voltage tester before an installer works on the equipment.

Exempt from classification according to Australian WHS regulations.

Classification of the hazardous chemical

Other hazards

This product is a Lithium Iron Phosphate Battery with certified compliance under the UN

Recommendations on Transport of Dangerous Goods, Manual of Tests and Criteria, Part III,

subsection 38.3. For the battery cell, chemical materials are stored in a hermetically sealed

metal case, designed to withstand temperatures and pressures encountered during normal

use. As a result, during normal use, there is no physical danger of ignition or explosion and

chemical danger of hazardous materials' leakage. However, if the product is exposed to a fire,

added mechanical shocks, decomposed, added electric stress by misuse, the gas release

vent will be operated. The battery cell case will be breached at the extreme. Hazardous

materials may be released. Moreover, if heated strongly by the surrounding fire, acrid or

harmful fume may be emitted.

5min

1.3.5 Measuring Equipment

1.3.6 Moisture Protection

1.3.7 Operation After Power Failure

05 06

1.4 Battery Safety Datasheet

1.4.2 Safety Datasheet

For detailed information please refer to the provided battery safety datasheet.

User Manual User Manual

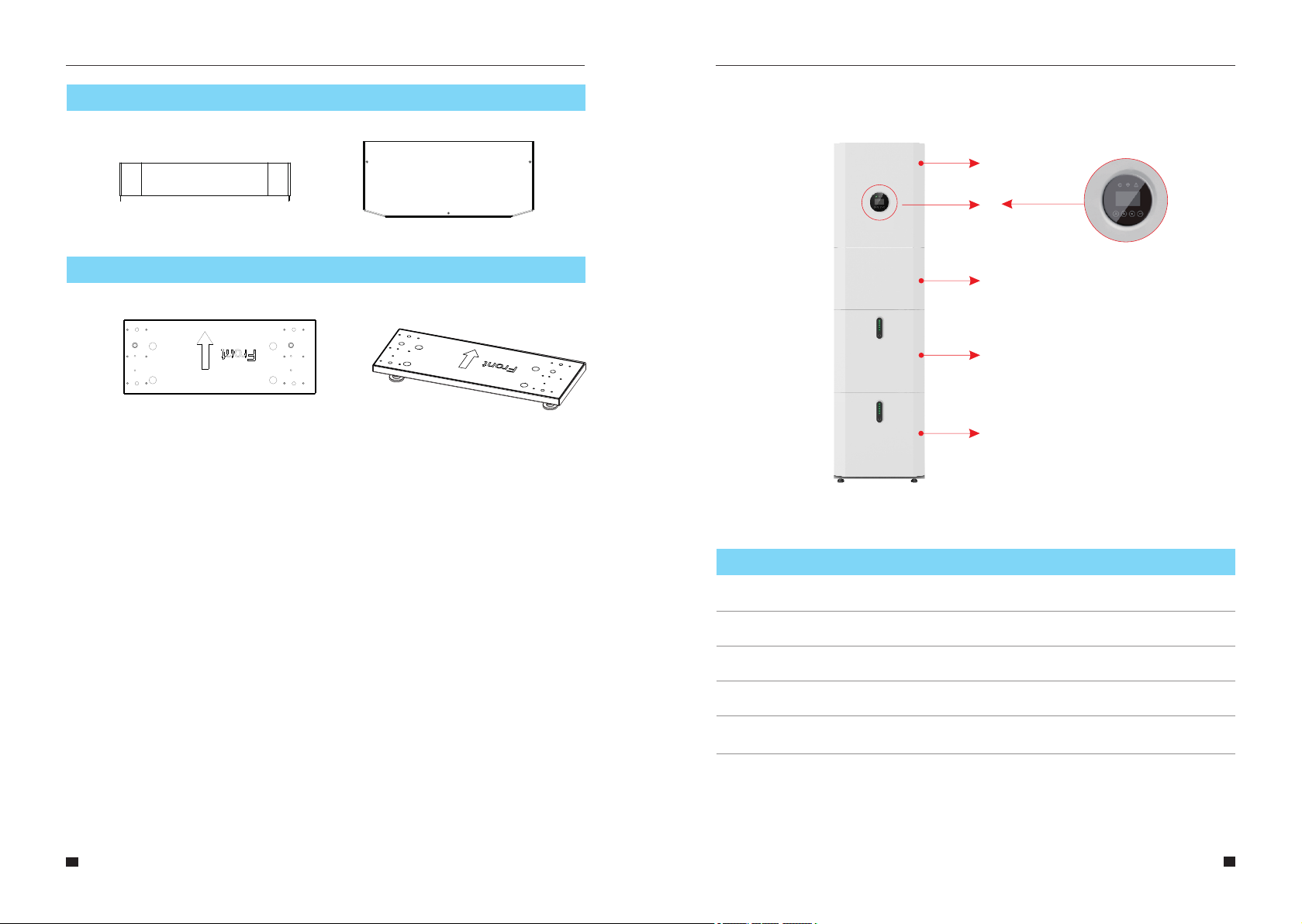

1.3.8. Information on environmental conservation and recycling

This Symbol indicates that the marked device must not be disposed of as normal

household waste. It must be disposed of at a collection center for the recycling of

electric and electronic equipment.