SETUP 3

2.1Unpacking and setting up the vehicle

C00103-01

Packaging 2

–Remove the box and the plastic packaging.

Info

To avoid damaging the motorcycle during the setup, leave the protective

film on the vehicle until you have finished.

–Remove the separate enclosure and unpack it. Check that the scope of delivery

is complete on the basis of the enclosed packing list.

–Have a lift stand available.

Lift stand (54829055000)

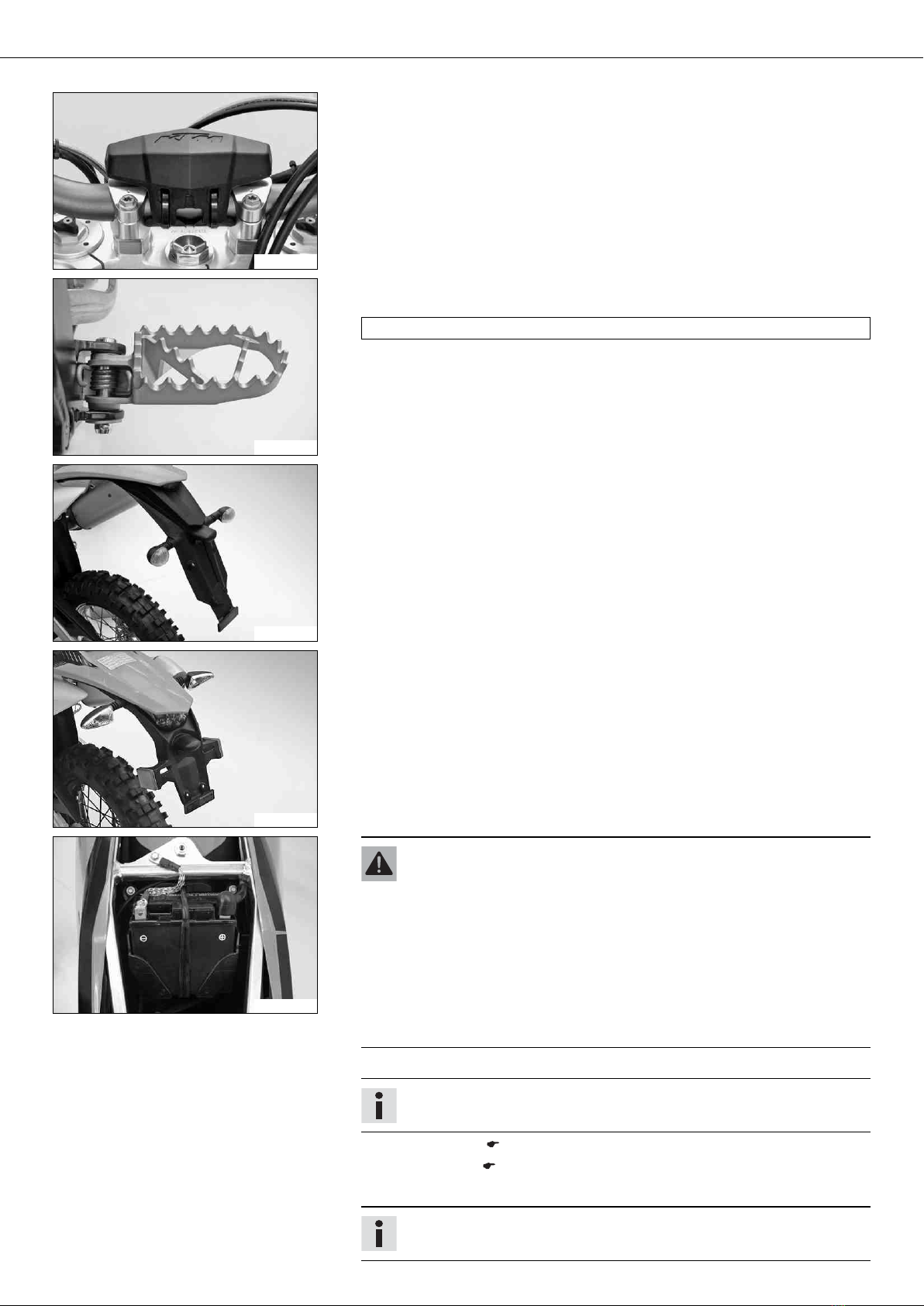

–Carefully loosen and remove the footrest mount.

Info

An assistant prevents the motorcycle from falling over.

601706-01

–Together with an assistant, take the vehicle off the palette.

–Position the vehicle on a lift stand.

–Check the vehicle for transport damage.

–Remove the headlight mask with the headlight. ( p. 8)

C00104-01

Package 12

–Remove the box and the plastic packaging.

Info

An assistant prevents the motorcycle from falling over.

To avoid damaging the motorcycle during the setup, leave the protective

film on the vehicle until you have finished.

–Remove the separate enclosure and unpack it. Check that the scope of delivery

is complete on the basis of the enclosed packing list.

C00105-01

–Have a lift stand available.

Lift stand (54829055000)

–Together with an assistant, take the vehicle off the palette.

–Position the vehicle on a lift stand.

–Check the vehicle for transport damage.

–Install the shock absorber. ( p. 9)

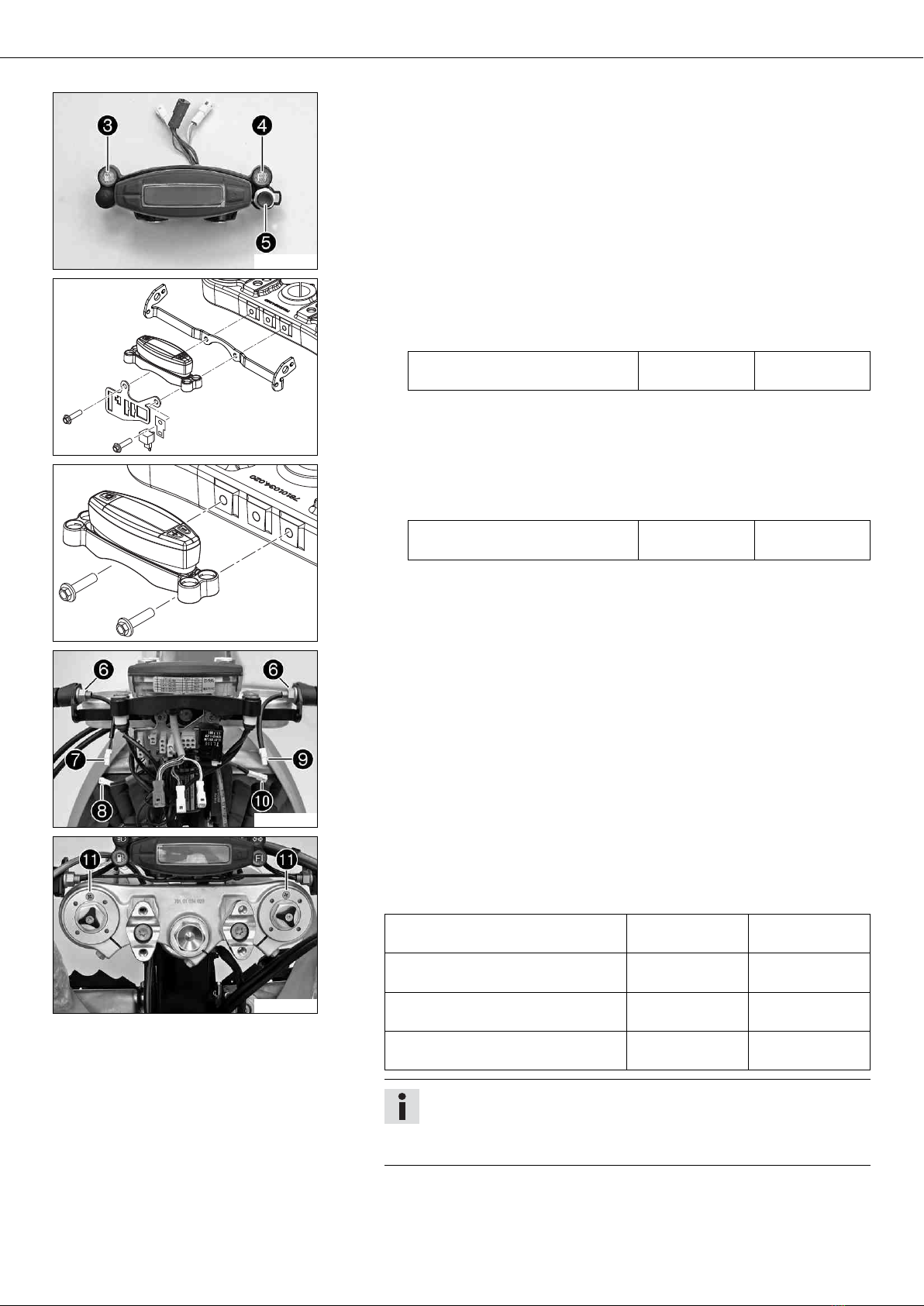

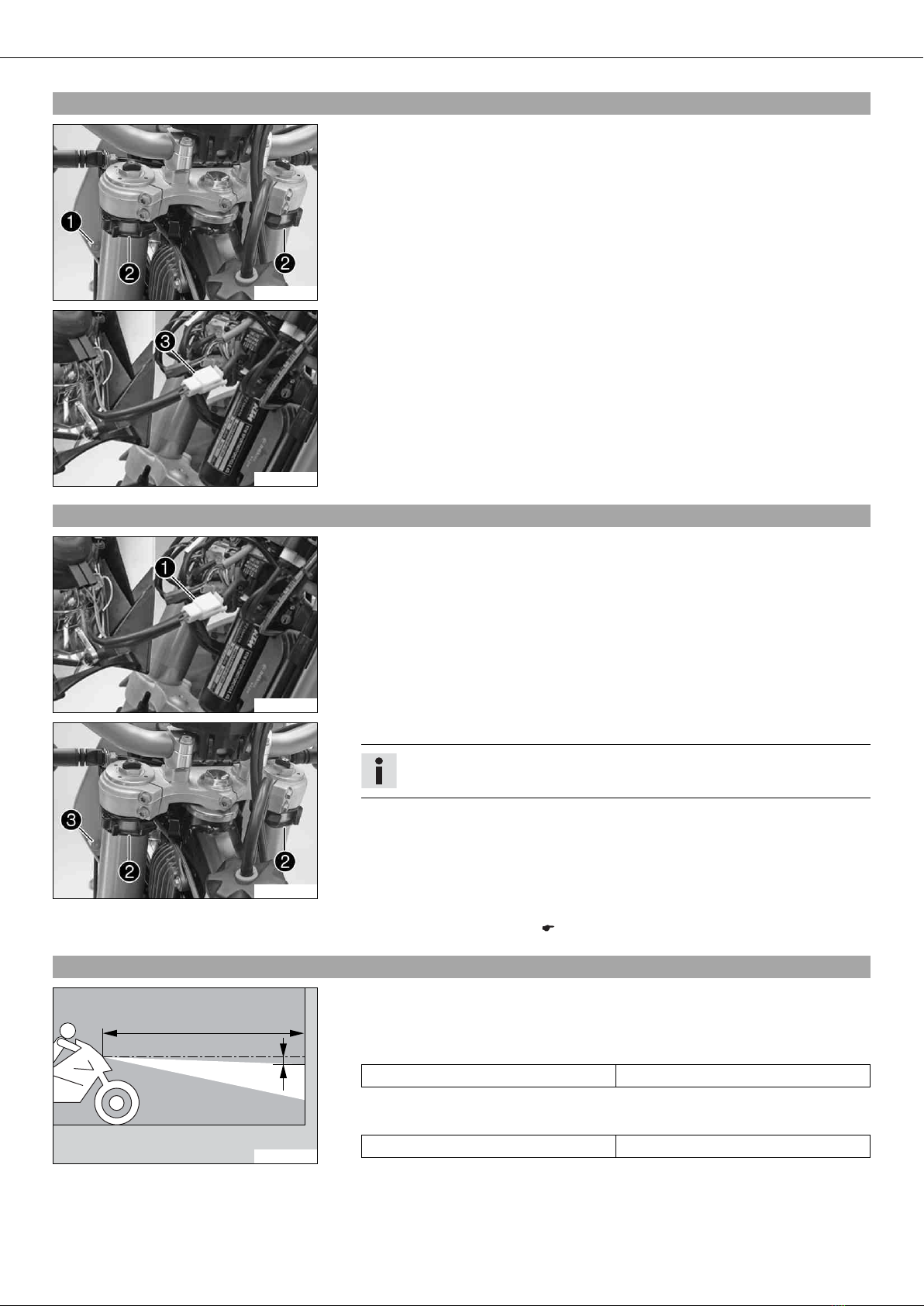

601704-10

(All EXC‑F models)

–Insert the indicator lamp with the blue and brown cable colors into

socket 1.

–Insert the indicator lamp with the blue and violet cable colors into

socket 2.

–Insert the indicator lamp with the brown/red and yellow/blue cable colors

into socket 3.

–Insert indicator lamp LED with the white and orange cable colors into

socket 4.