When attaching the tongue to the back of the tow vehicle, tighten the screw pin

shackle clevis firmly. Property damage or bodily injury may occur if the screw pin

shackle clevis unturns and the wing mower becomes unattached from the tow

vehicle.

The hitching system is designed so that the wing mower can be pulled directly behind a tow

vehicle without a mower deck or as a left or right wing mower when towed behind a tow vehicle

with or without a mower deck.

Note: When pulling the wing mower directly behind, it is most maneuverable when the hitch

pivot is fastened on the left carrier arm. See Figure 1.When pulling the wing mower in

the offset position, it is most maneuverable to have the hitch pivot fastened on the right

carrier arm. See Figure 1.

The tongue is designed to adjust from left to right within the hitch pivot. This allows the wing

mower and tow vehicle, with a mower deck, to have proper overlap. Overlap is more critical in

tight areas where a lot of maneuvering is required. This overlap will eliminate most skips between

the tow vehicle and wing mower. In large open areas the overlap is not as critical and should be

adjusted to the user’s preference.

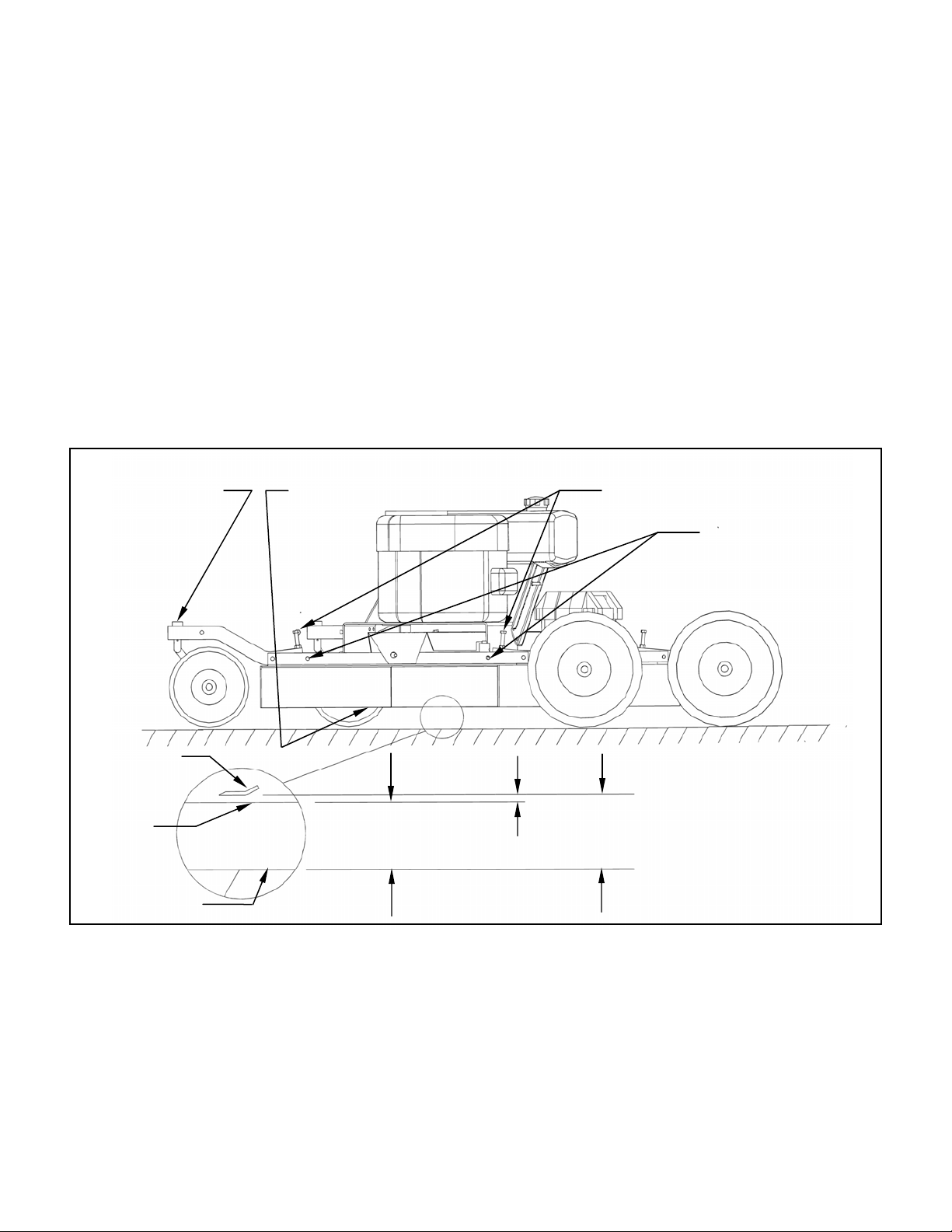

B. ADJUSTING CUTTING HEIGHT

Shut off all engines and allow the mower blades to come to a complete stop on the

wing mowers and on the tow vehicle before adjusting the cutting height.

The cutting height can be adjusted in a range from 1.0" to 4.0". This is accomplished by adjusting

the height adjusting bolts on each of the four corners of the wing mower. See Figure 3. Turn the

bolts clockwise to raise the mower cutting height and counter-clockwise to lower the mower

cutting height.

When more than one mower is used at a time, it is very important to have all the mowers adjusted

as close to the same cutting height as possible to obtain a high quality cutting job.

Adjust the mowers as follows:

1. Pull the mowing unit on to a smooth, level surface.

2. Adjust the tow vehicle mower deck (If applicable) to the desired cutting height and level both

fore and aft and side to side.

3. Measure the distance from the level surface to the mower blade cutting edge on the tow

vehicle.

Shut off tow vehicle engine and allow mower blades to stop completely before

attempting to measure the cutting height.

3