36 EKV 6800.1M

UK

ENGLISH

TECHNICAL CHARACTERISTICS . . . . .35

1. DESCRIPTION . . . . . . . . . . . . . . . . . . . .37

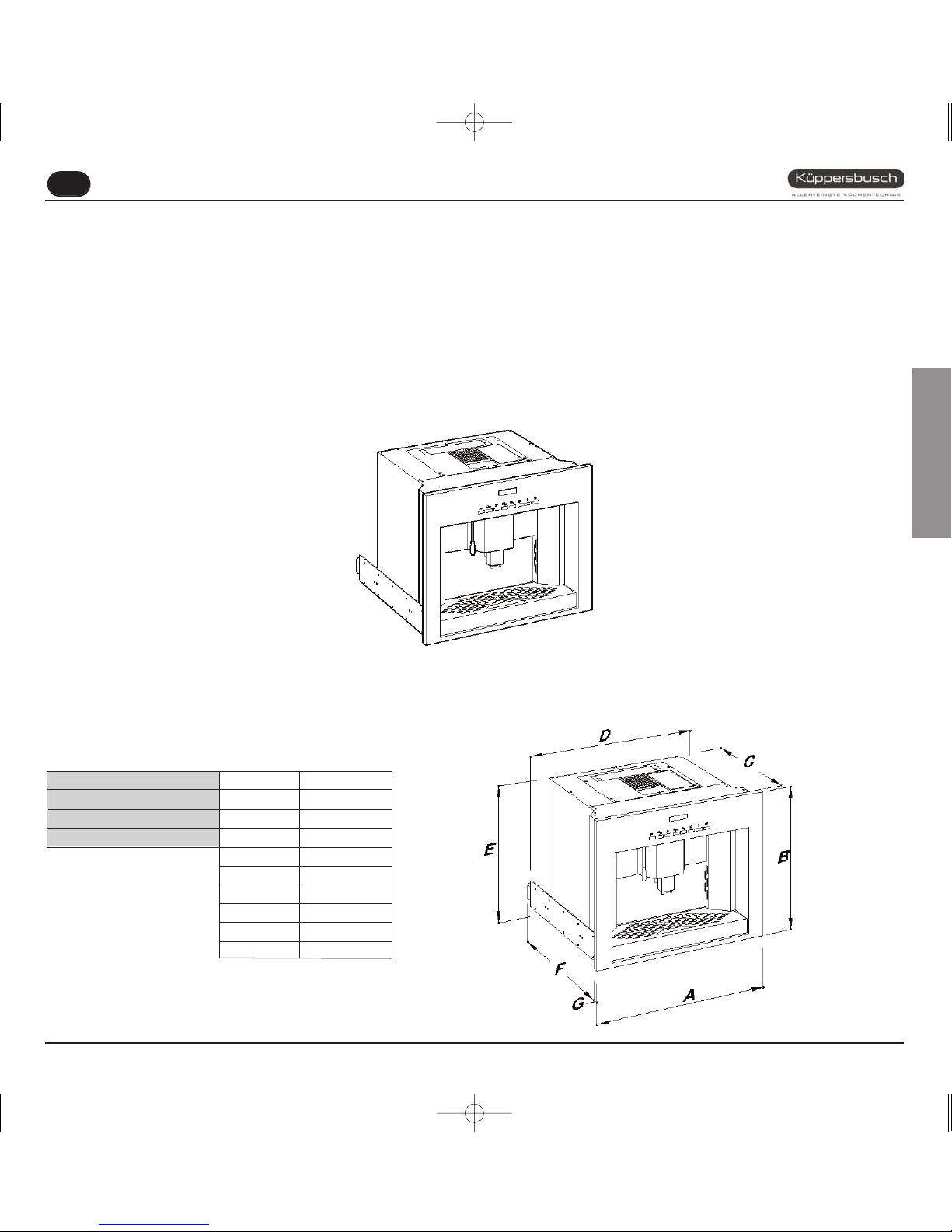

1.1 KEYBOARD DESCRIPTION (Standard configuration) . . .38

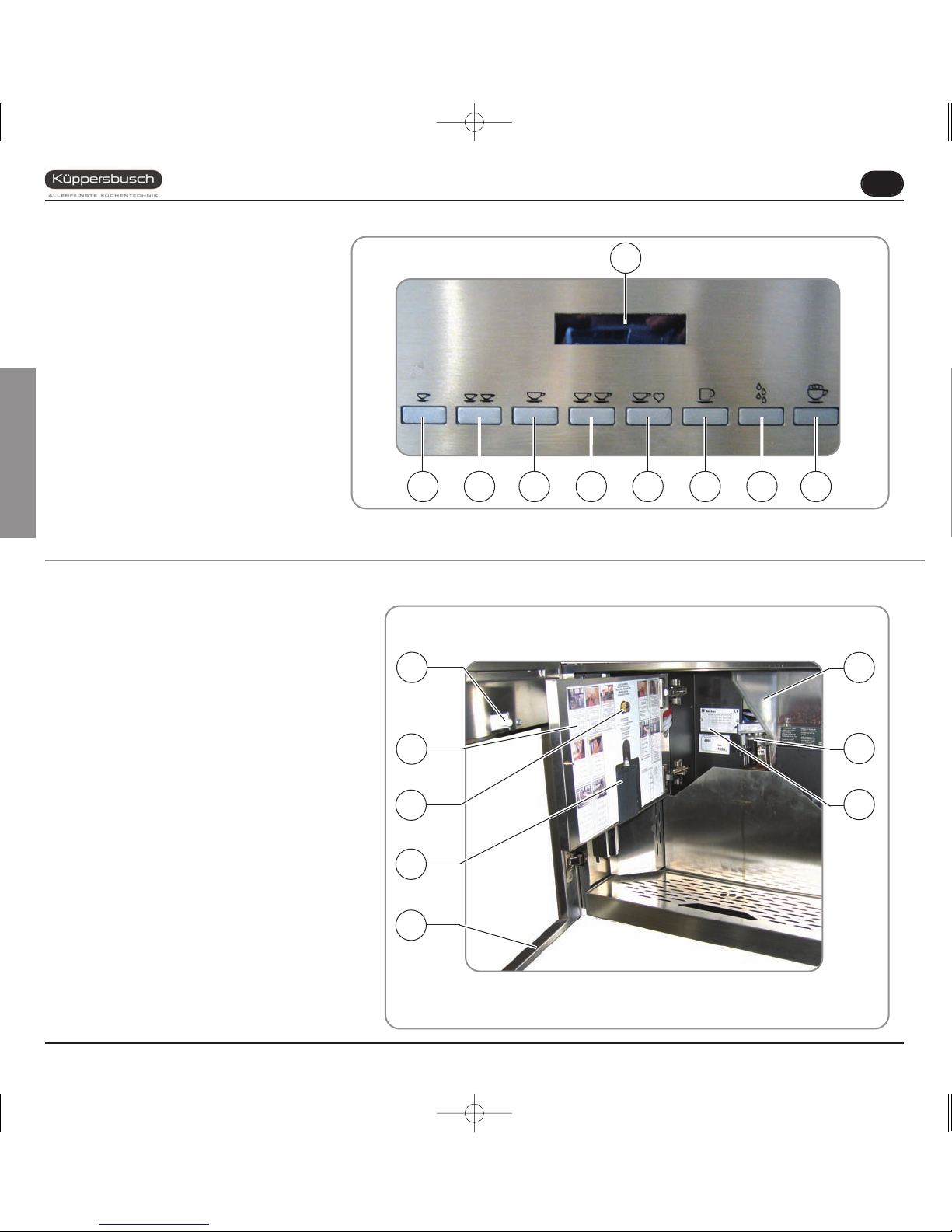

1.2 MICROBAR INTERNAL DESCRIPTION . . . . . . . . . . . . .38

2.

SAFETY INSTRUCTIONS . . . . . . . . . . . .39

3. TRANSPORT AND HANDLING . . . . . . . .41

3.1 MACHINE IDENTIFICATION . . . . . . . . . . . . . . . . . . .41

3.2 TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.3 HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

4.

PRELIMINARY OPERATIONS . . . . . . . . .42

4.1 FILLING THE APPLIANCE . . . . . . . . . . . . . . . . . . . .42

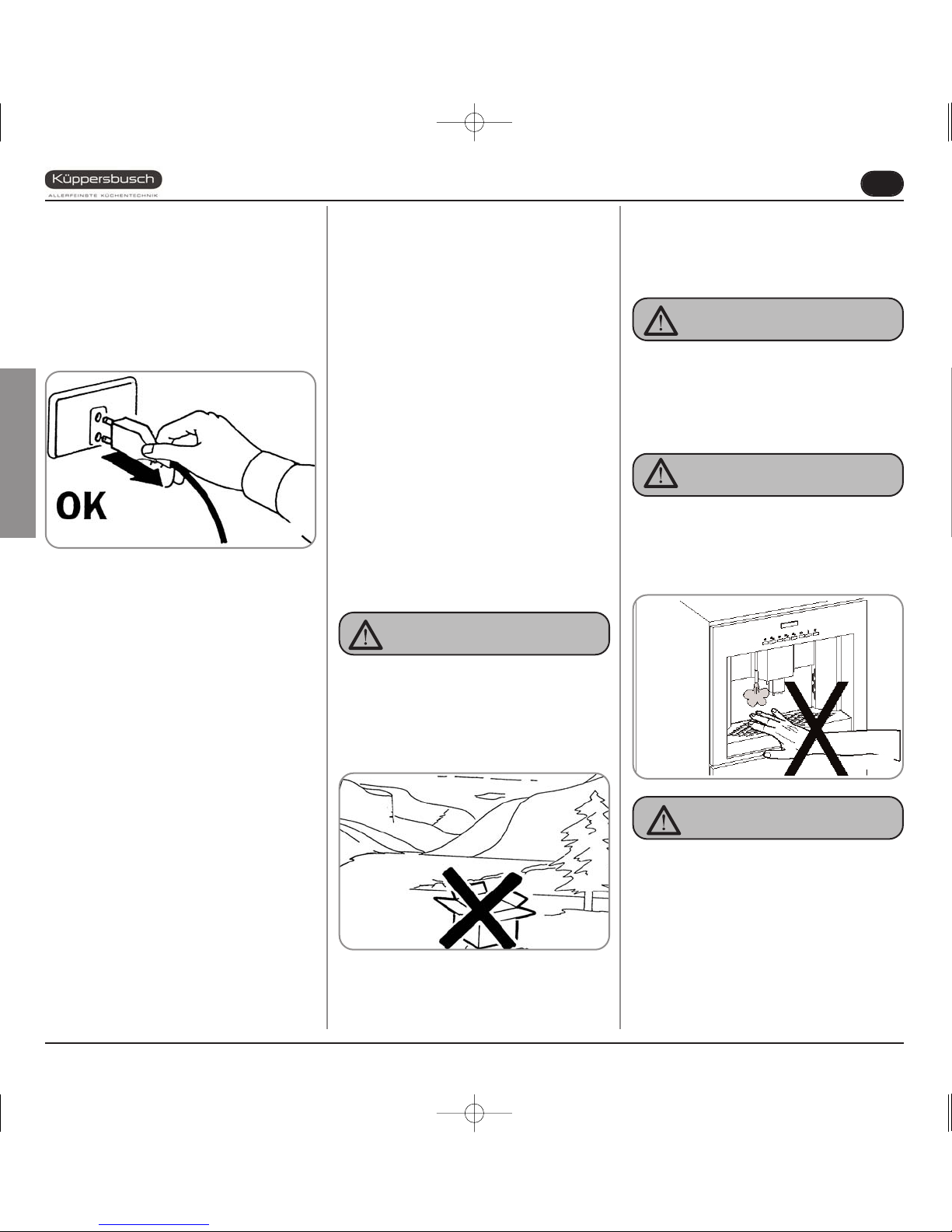

4.2 MACHINE INSTALLATION

(VERSION FOR DIRECT CONNECTION) . . . . . . . . . .42

4.3 SWITCHING ON . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4.4 SWITCHING OFF . . . . . . . . . . . . . . . . . . . . . . . . . . .44

5.

ASSEMBLY INSTRUCTIONS FOR

QUALIFIED PERSONS . . . . . . . . . . . . . . .45

5.1 INSTRUCTIONS FOR BUILT-IN ASSEMBLY . . . . . . . .45

5.2 EKV 6800 .1M BUILT-IN UNIT DIMENSIONS . . . . . . .45

5.3 BUILT-IN INSTALLATION . . . . . . . . . . . . . . . . . . . . .45

5.4 NUMBER OF SPACER PLATES . . . . . . . . . . . . . . . . . .46

5.5 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

5.6 TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.

ADJUSTMENTS TO BE MADE

BY A QUALIFIED TECHNICIAN ONLY . .48

6.1 GRINDING ADJUSTMENT . . . . . . . . . . . . . . . . . . . . .48

6.2 CAPPUCCINO MAKER AIR ADJUSTMENT

(foam amount and density . . . . . . . . . . . . . . . . . . . .48

6.3 MILK FLOW ADJUSTMENT

(Temperature adjustment) . . . . . . . . . . . . . . . . . . . .48

7.

USE . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

7.1 STANDARD CONFIGURATION . . . . . . . . . . . . . . . . .49

7.2 SWITCHING ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

7.3 SWITCHING OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

7.4 HEIGHT-ADJUSTABLE COFFEE DISPENSER . . . . . . . .50

7.5 HOW TO MAKE COFFEE . . . . . . . . . . . . . . . . . . . . . .50

7.6 HOW TO MAKE 2 COFFEES . . . . . . . . . . . . . . . . . . .50

7.7 PREPARING DECAFFEINATED COFFEE IN POWDER 51

7.8 PREPARING LONG COFFEE . . . . . . . . . . . . . . . . . . . . .51

7.9 HOW TO MAKE CAPPUCCINO . . . . . . . . . . . . . . . . .51

7.10 DISPENSING HOT WATER . . . . . . . . . . . . . . . . . . . . . .52

8.

PROGRAMMING . . . . . . . . . . . . . . . . . . .53

8.1 LEGENDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

8.2 PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

8.3

EXITING PROGRAMMING

. . . . . . . . . . . . . . . . . . . . .54

8.4 PROGRAMMING CYCLE

USER MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

8.5

PROGRAMMING CYCLE

TECHNICIAN MODE . . . . . . . . . . . . . . . . . . . . . . . . . . .56

9. SPECIAL MACHINE

SCALING FUNCTIONS . . . . . . . . . . . . . .60

9.1 RESETTING THE CLEANING FILTRE

LITRE COUNTER . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

9.2 RESETTING WASHING CYCLES . . . . . . . . . . . . . . . .60

9.3 RESETTING MACHINE PARAMETRES . . . . . . . . . . .60

9.4

HANDLING MANUAL COFFEE DELIVERY GROUP

’. .60

10. CLEANING AND MAINTENANCE . . . . . .61

10.1 CLEANING THE OUTSIDE OF THE MACHINE . . . . . .61

10.2 CLEANING THE DELIVERY UNIT

AND THE MILK FOAMER . . . . . . . . . . . . . . . . . . . . . .62

10.3 REINSTATING AN INTERRUPTED

WASHING CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . .63

10.4 CLEANING THE MILK FOAMER . . . . . . . . . . . . . . . .63

11. STANDARD SETTING TABLE . . . . . . . .64

12. MACHINE FUNCTIONS MESSAGES . . . .65

13. MACHINE BLOCK

ALARM MESSAGES . . . . . . . . . . . . . . . .67

INDEX