VEHICLE TUBING INSTALLATION

1. Mount all components in a suitable location, preferably in a high area above the air system .

Do not mount in engine compartment or near any source of heat or dirt . The system may be

connected to any point in the vehicle's air system .

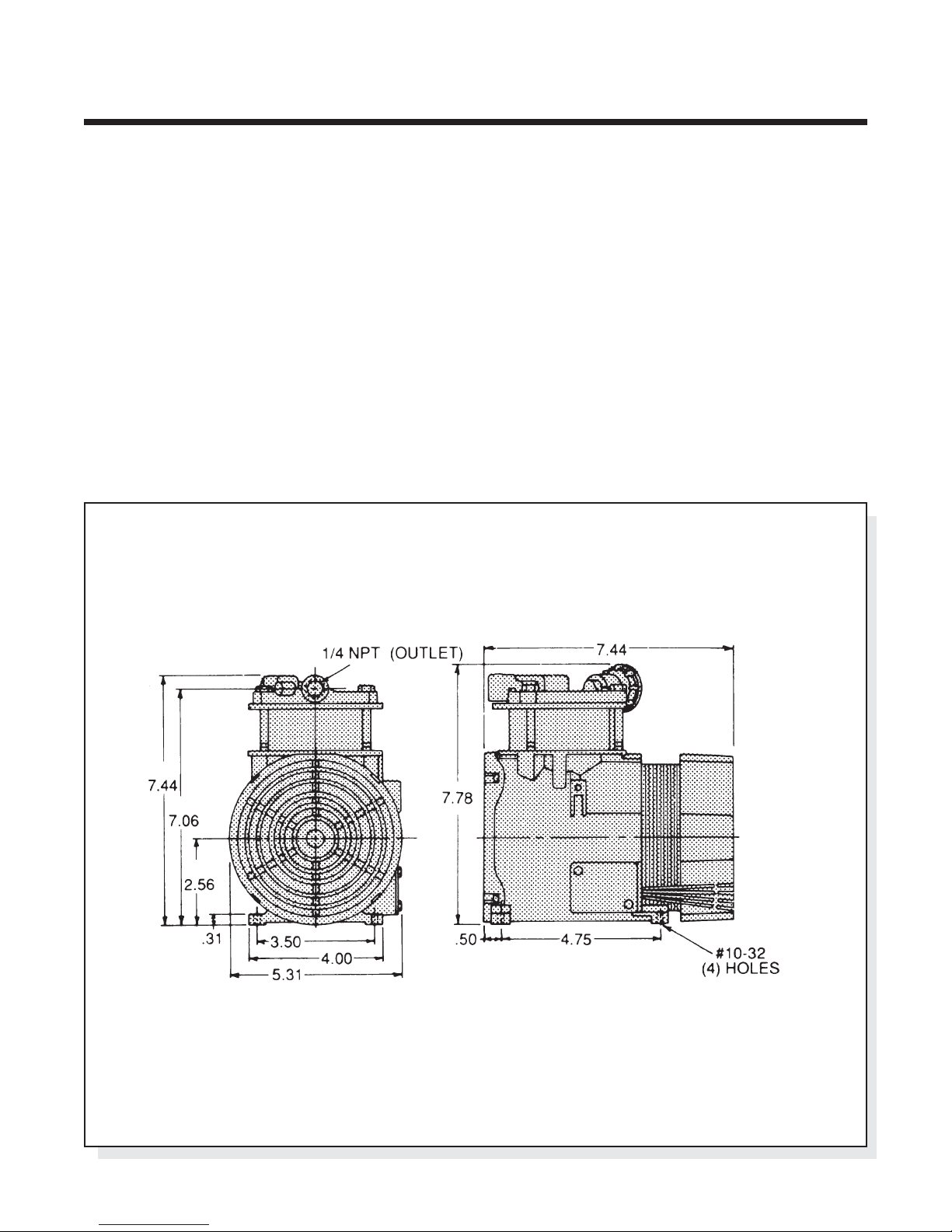

2. Mount air compressor in a vertical position as shown.

3. CAUTIONno condensate or water must be allowed to enter or accumulate in the output of the

AutoPump. RouteoutputpressurelinedownwardfromAutoPumptopermitmoisturetodrain

away . Water in the pump outlet will induce failure .

4. All connection for air lines are 1/4" NPT . Use Teflon tape, or equivalent on all connections to

insure no leakage of air.

5. The recommended installation of the Auto Pump air compressor system is shown below.

6. Note that an external check valve is located beteen the compressor and the pressure switch.

no additional check valve is required.

7. Mount the air compressor. Connect a suitable piece of flexible tubing from the outlet port of

compressor to the air tank . (Tubing and connectors are not supplied .)

8. An optional Mounting Plate 091-9H-1 is available to reduce any vibration and noise from Auto

Pump and to simplify pump mounting.

NOTE: Compressor must be mounted above air

tank to assure that moisture will flow away from

compressor.