K U N S T S T O F F –V E R B I N D U N G S –T E C H N I K G M B H Stand: Okt-12

Werkering 6 –33609 Bielefeld –Tel. 0521 / 93207-0 –Fax 0521 / 93207-11 Kap. 7 –Seite 2

7.1 Introduction

7.1.1 Purpose

Qualified staff must be able to correctly interpret and implement safety in-

structions and warnings. In addition, they must be familiar with the safety

concepts for automation technology and have obtained a corresponding

training. Use by unqualified staff or non-observance of the warnings in this

manual or the warning signs applied to the system components can result in

material damage or injuries to people.

Proper use means

Work on the EWS components is performed by specialists or appropri-

ately trained persons.

The EWS system components are in a technically fault-free condition.

The EWS system components are used in compliance with this product

manual.

It is recommended to thoroughly work through these instructions before using

the EWS system components.

7.1.2 General

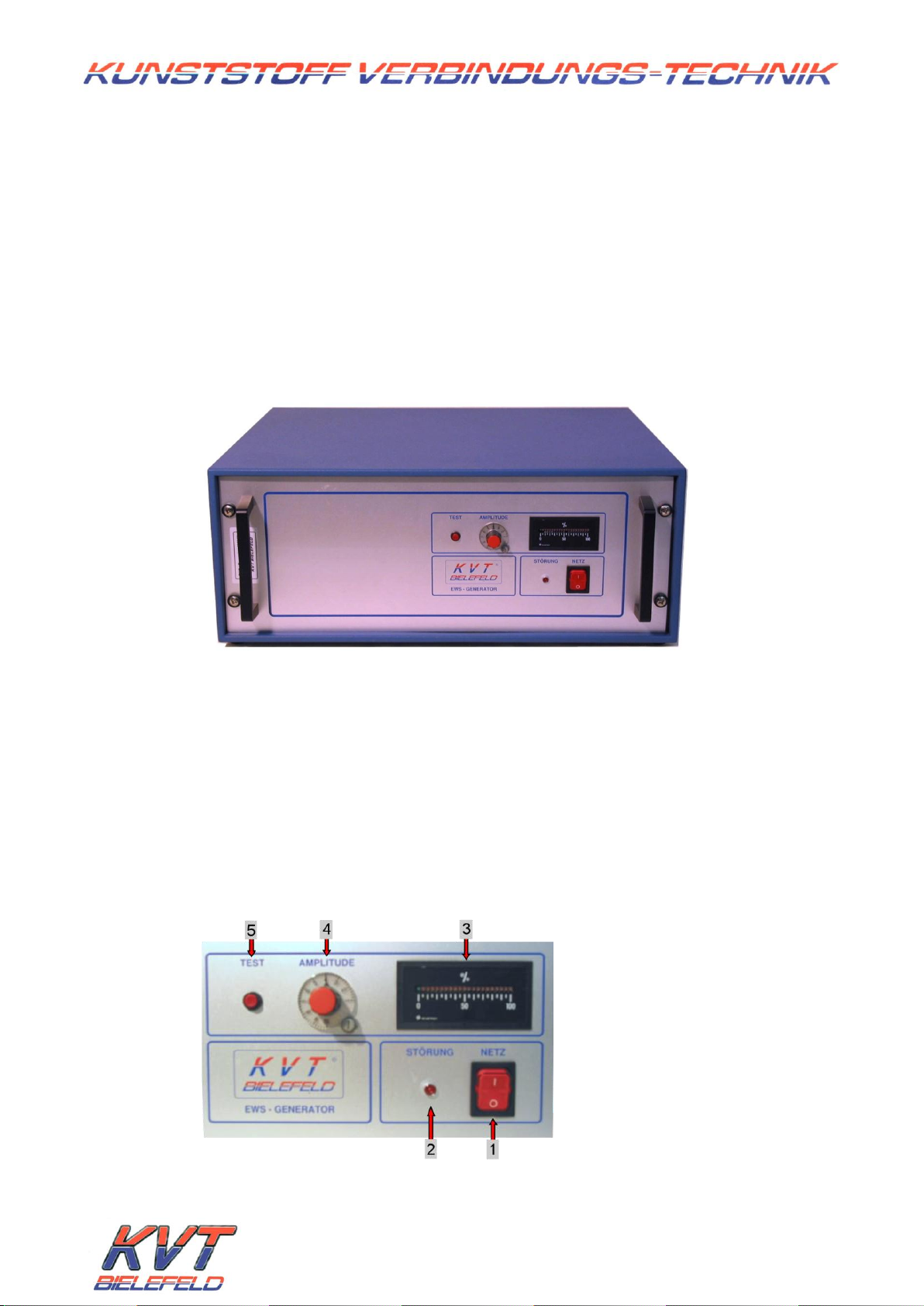

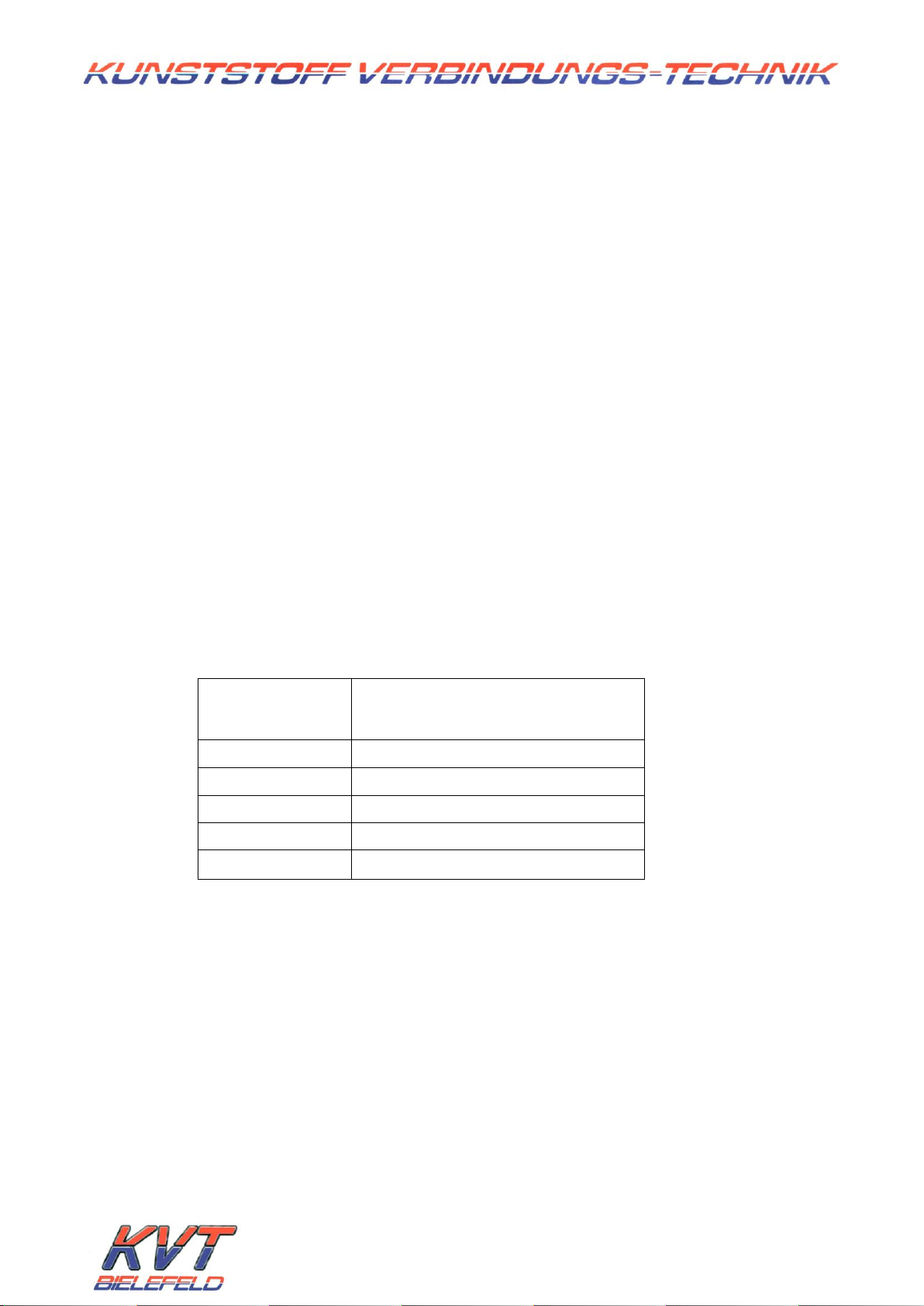

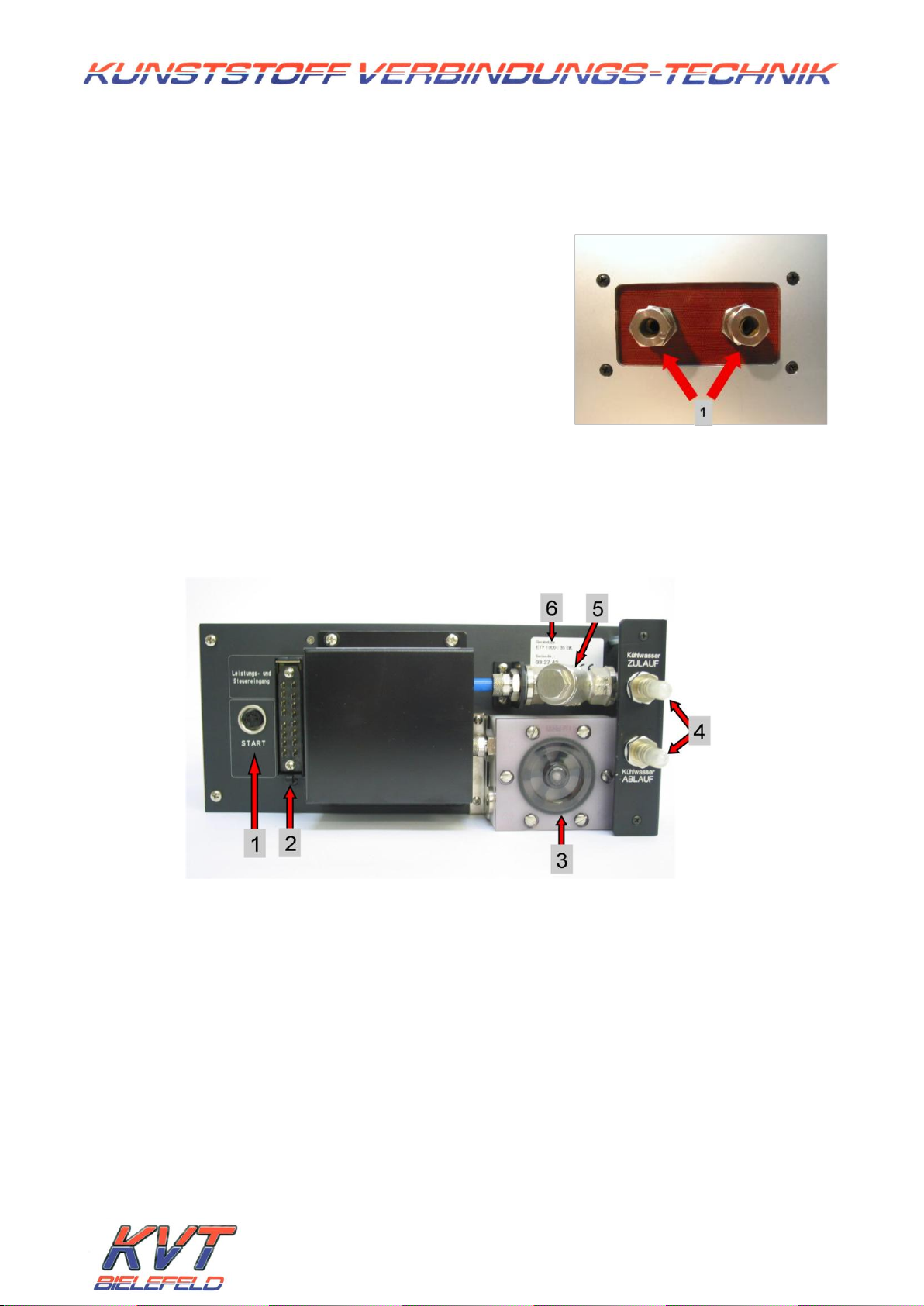

The requirement for a cutting edge joining technology has been achieved

by KVT Bielefeld with the development of EWS generators and electromag-

netic converters. It specifically concerns the installation of metallic compo-

nents and thread inserts in plastic parts.

High requirements with regard to strength and precision can be attained

with the EWS processes from KVT Bielefeld.

The EWS process is characterised by the following properties:

Contactless heating of the metal parts

Exact application of the necessary

energy requirement

Exact reproducibility of the assembly

temperature

Low thermal load on metal and plas-

tic

Shortest heating-up times

Shortest cooling-down times using

cold pressfit tool

Installation tolerances smaller than

0.05 mm

No material damage due to over-

heating

No hot machine parts

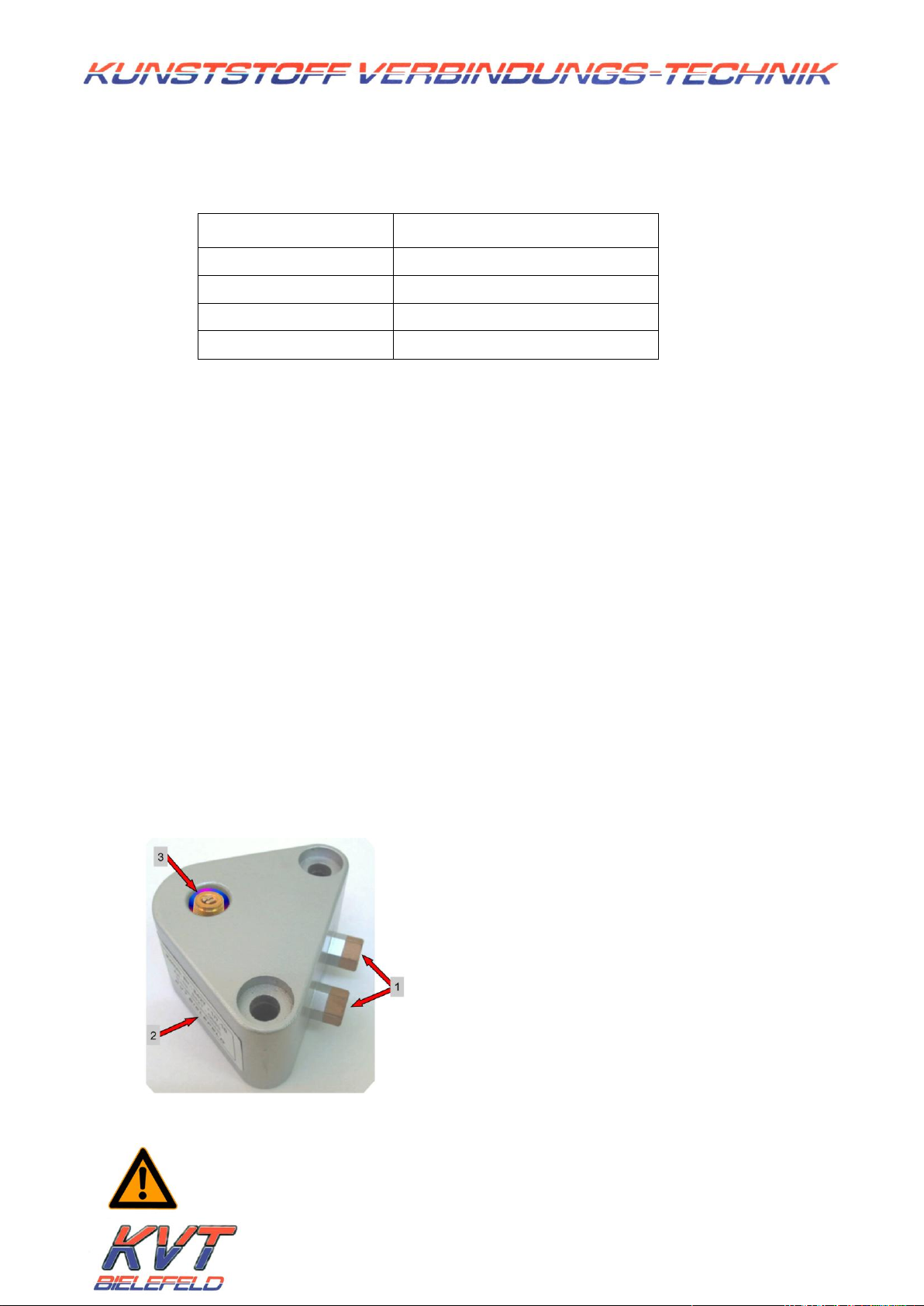

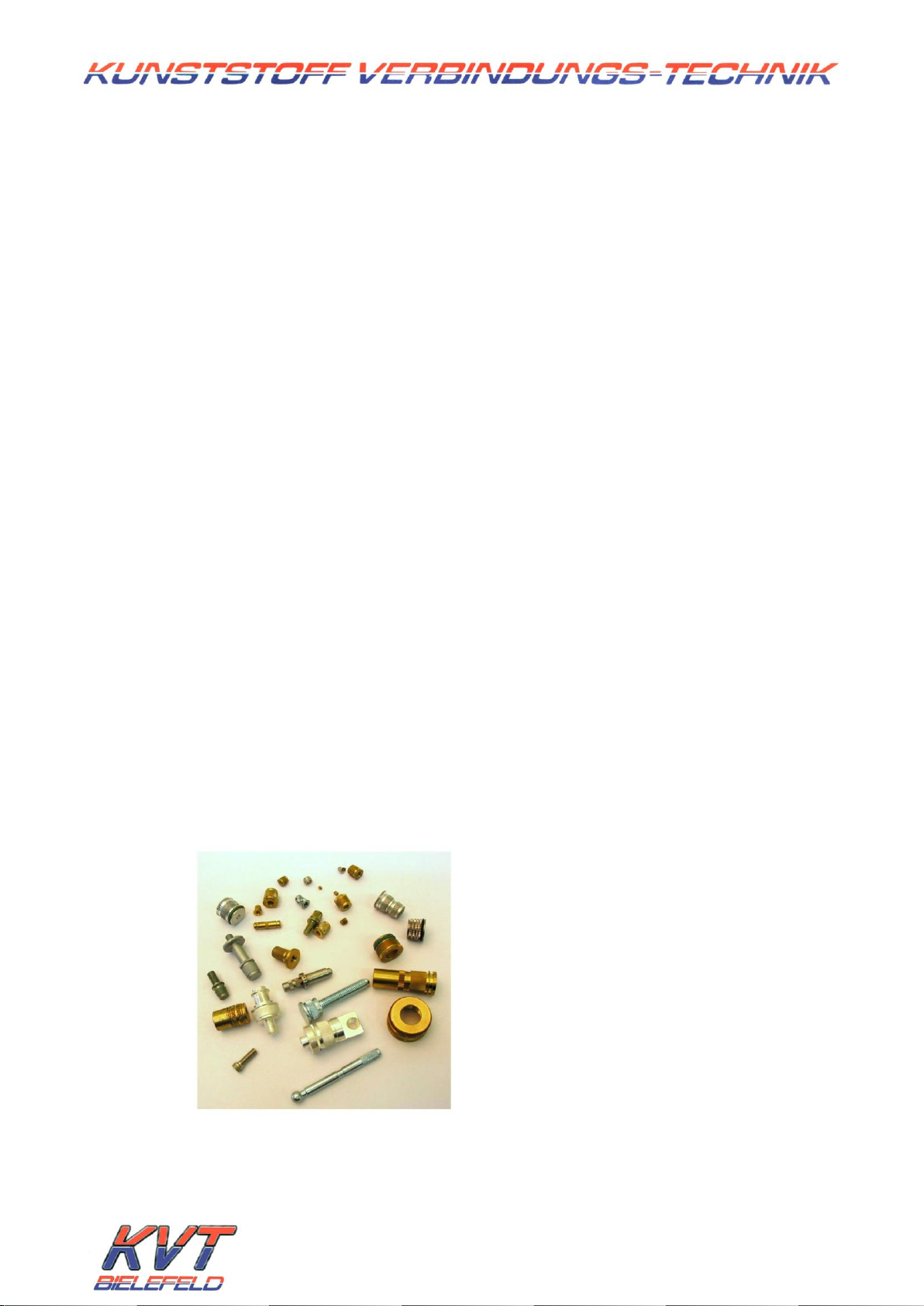

Photo 1: metallic assembly components